Threshing device

A technology of threshing device and conveying device, which is applied in the direction of threshing equipment, application, agricultural machinery and implements, etc., and can solve the problems of large size and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

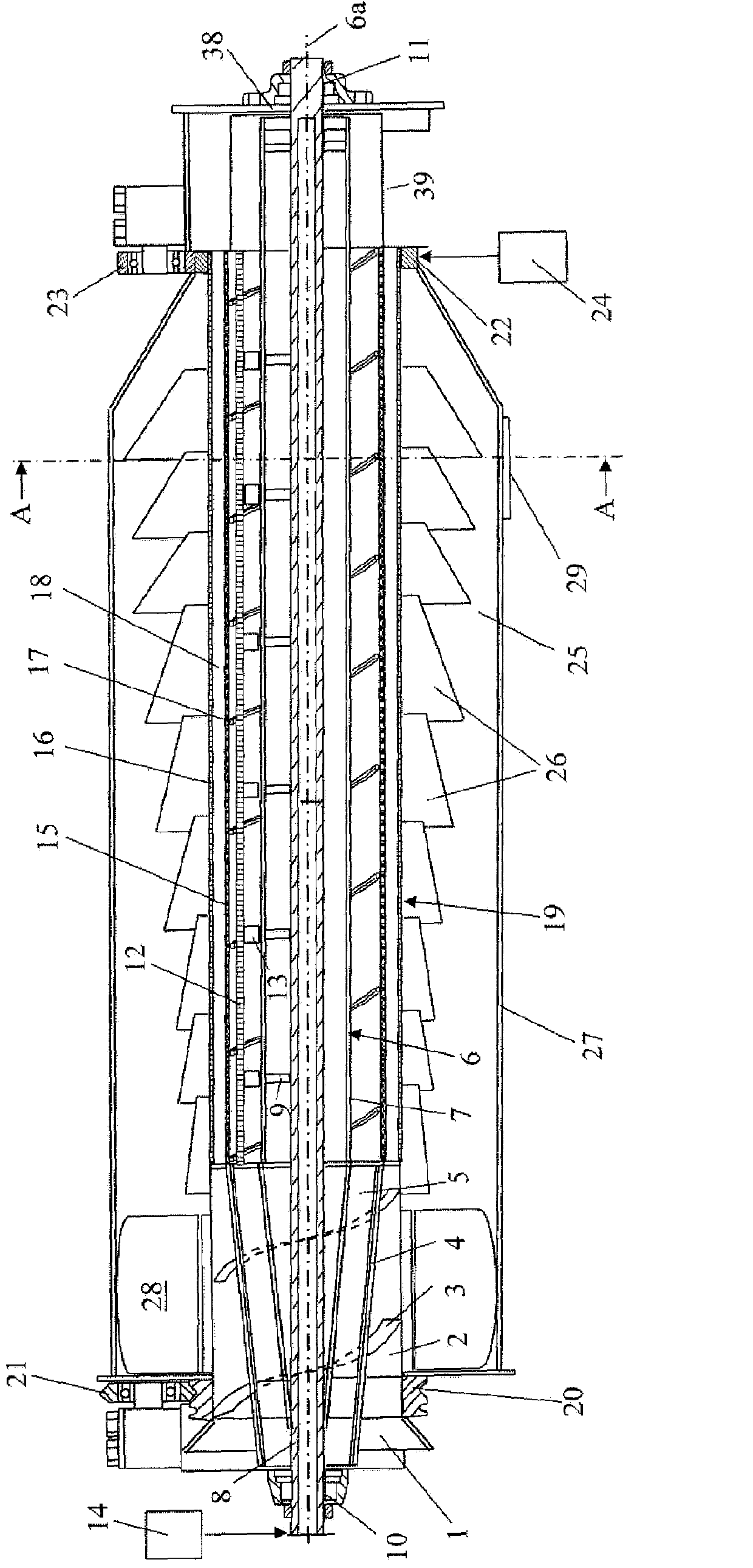

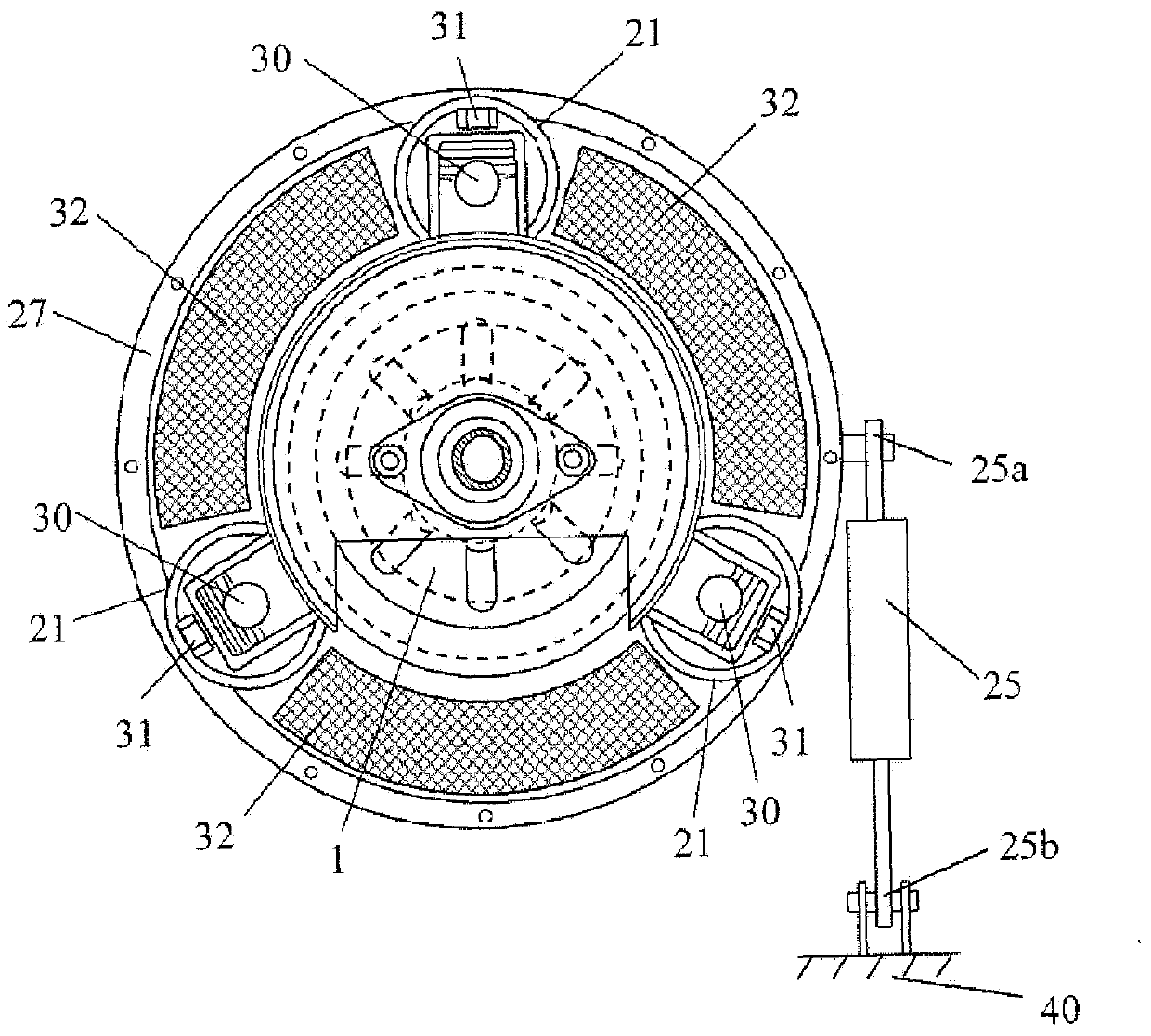

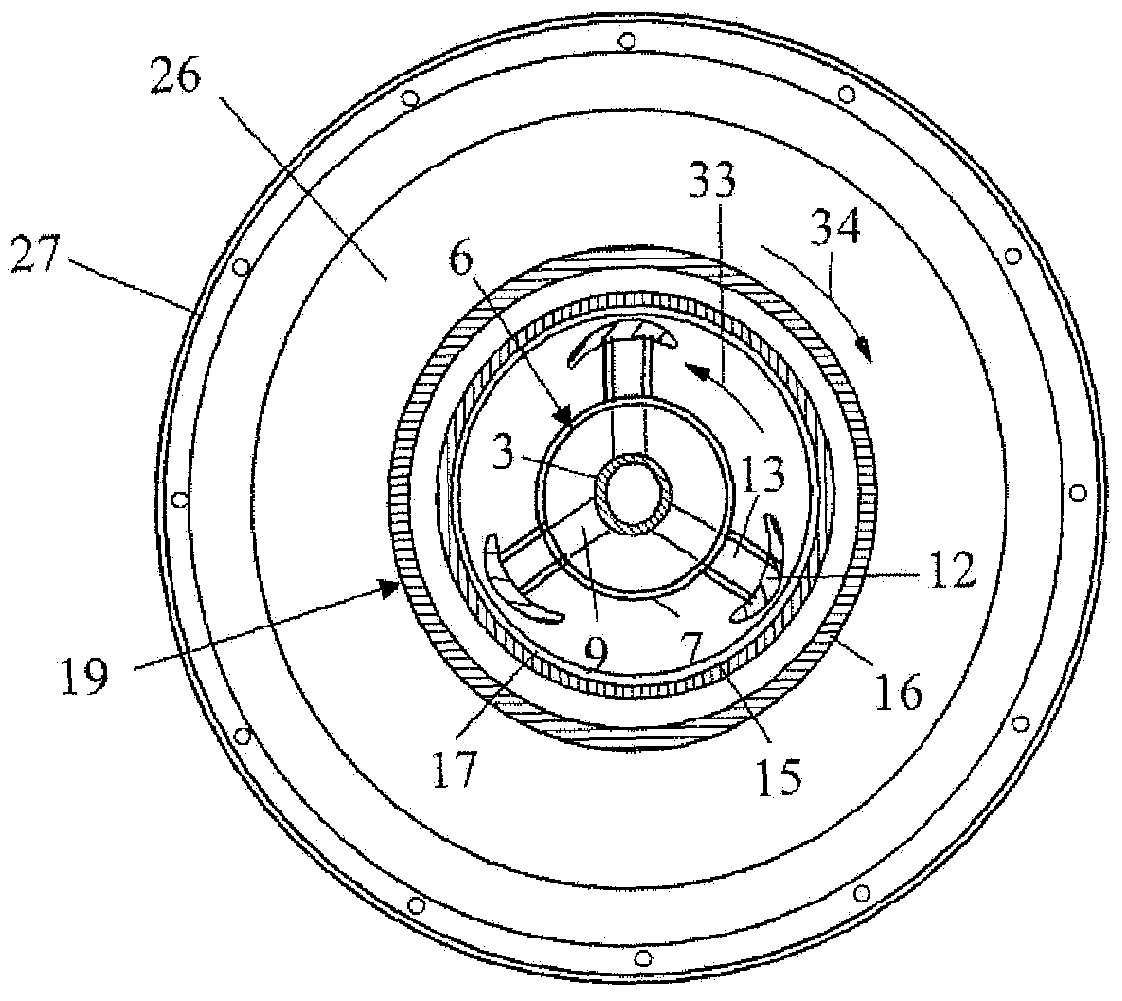

[0019] figure 1 A threshing device according to the invention is shown. The material, which is advantageously seed straw, is fed into the threshing device through an inlet 1 located on a first gable side of the threshing device. The threshing device comprises an outer space 2 connected to the inlet 1, in which a screw feeder 3 is arranged. Several inclined elongated elements 4 form a conical section between the outer space 2 and the inner space 5 . The threshing device comprises a first rotatable unit 6 which is rotatably arranged around a central axis 6a. The first rotatable unit 6 comprises a shaft 8 connected to the radially outward cylindrical portion 7 by a plurality of first connection elements 9 . The shaft 8 is rotatably mounted in a first bearing 10 on the first end face side of the threshing device and a second bearing 11 on the second end face side of the threshing device. The cylindrical portion 7 is connected to three elongated flails 12 by a plurality of seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com