Pressurizer water level measurement method based on digitalization technology

A technology of water level measurement and voltage stabilizer, which is used in the display of liquid level indicators through pressure measurement, monitoring of nuclear reactors, reactors, etc. It can solve the problems of difficulty in calculating density and thermal expansion, complexity, and inconvenience in use, so as to reduce the burden. , the effect of improving the accuracy of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0023] A method for measuring the water level of a voltage stabilizer based on digital technology, which includes:

[0024] (1) Instrument system settings

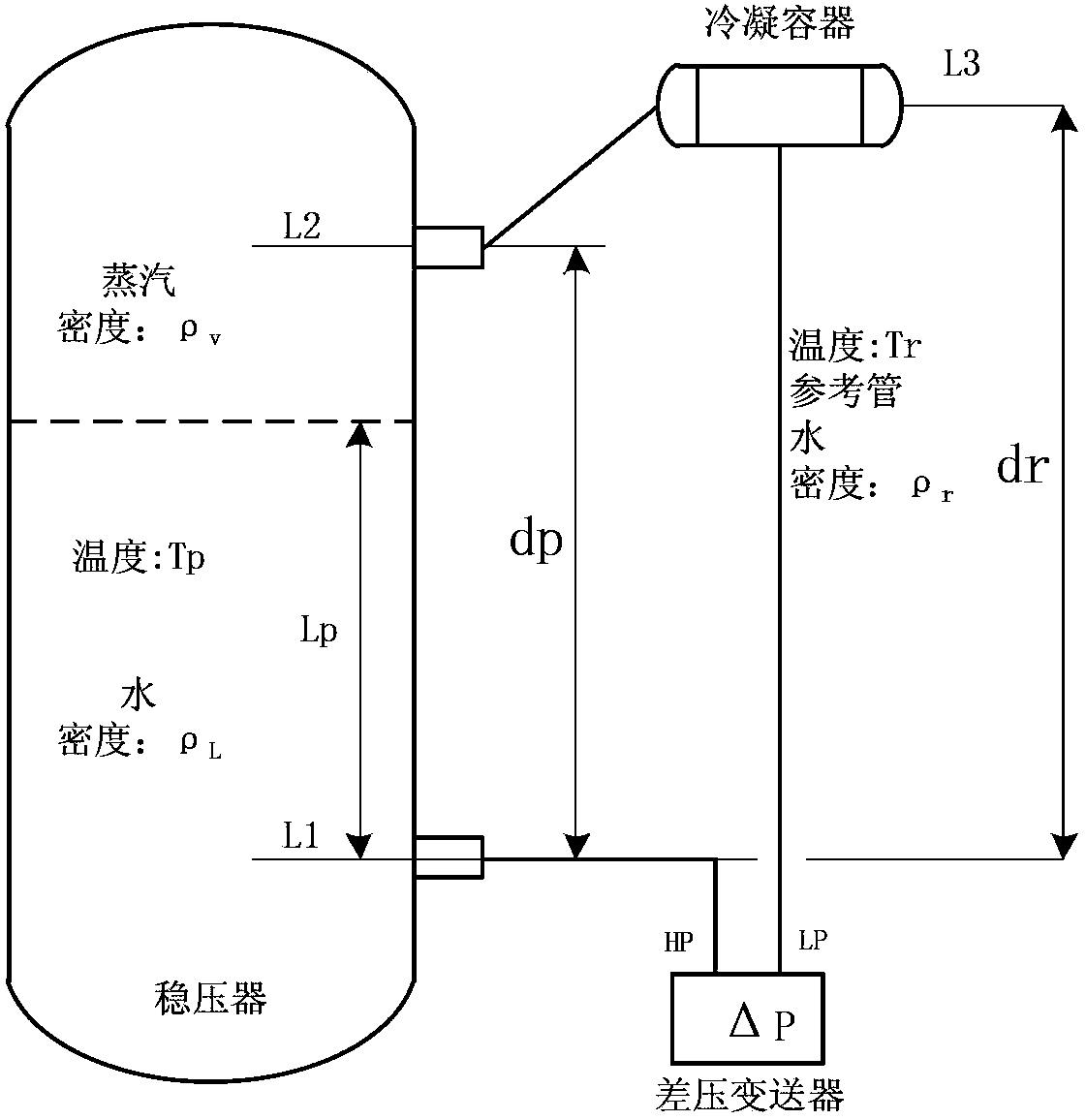

[0025] The barostat is equipped with 3 or 4 mutually independent redundant measurement channels, each channel includes a barostat pressure measurement, a barostat water level differential pressure measurement, and a thermometer can be set in the middle of the reference tube for the barostat water level measurement Instrument tube temperature (this thermometer can also be left unset).

[0026] The signal of each channel is collected by the signal processing equipment corresponding to the protection channel, and output to the control system through the isolated output module.

[0027] (2) Obtain basic parameters

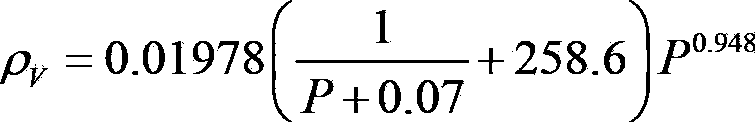

[0028] Under cold working conditions (around 25°C), measure the water level of the voltage sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com