Substrate, liquid crystal display panel and display device

A liquid crystal display panel and display device technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven cell thickness, bad phenomenon, large amount of compression deformation of spacers, etc., and achieve the effect of uniform cell thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An embodiment of the present invention provides a substrate for a liquid crystal display panel, on which a plurality of spacers are provided for supporting the thickness of the liquid crystal display panel.

[0029] In a specific example:

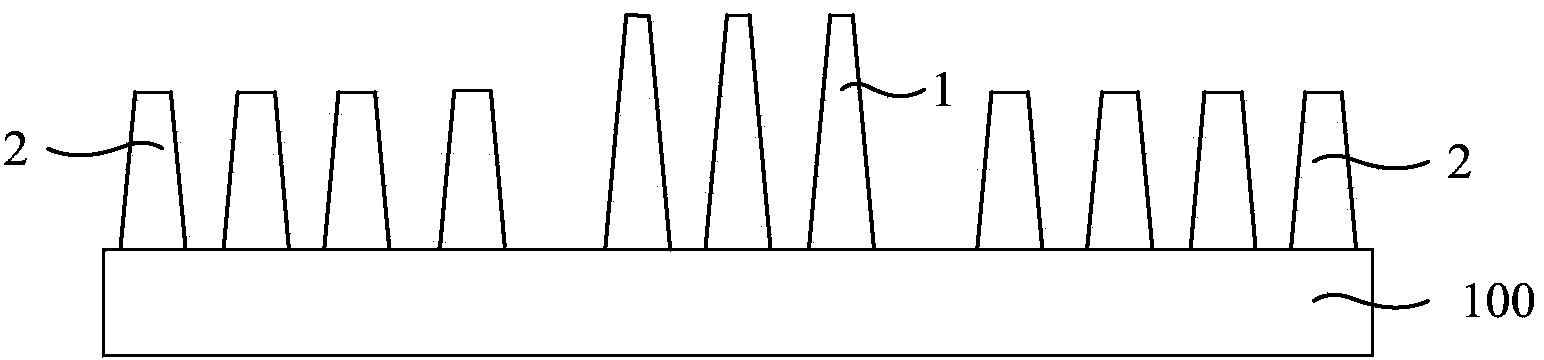

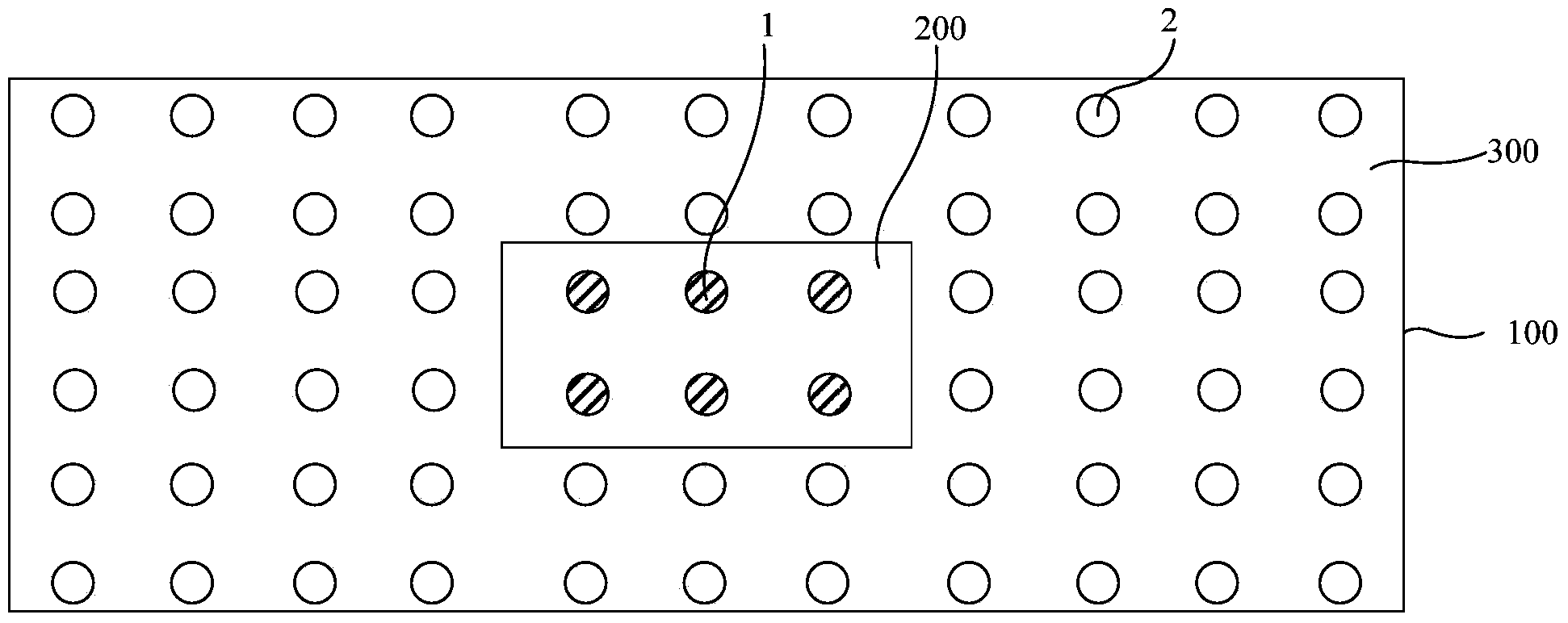

[0030] combine figure 2 and image 3 As shown, when the liquid crystal display panel is small, the substrate 100 can be configured to include a central region 200 and a first peripheral region 300 , wherein the first peripheral region 300 surrounds the periphery of the central region 200 without overlapping each other.

[0031] A plurality of first spacers 1 with the same height and a plurality of second spacers 2 with the same height are arranged on the substrate 100, wherein the first spacers 1 are located in the central area 200, and the second spacers 2 are located in the second spacer. A peripheral area 300 , and the height of the first spacer 1 is greater than the height of the second spacer 2 .

[0032] In another specific...

Embodiment 2

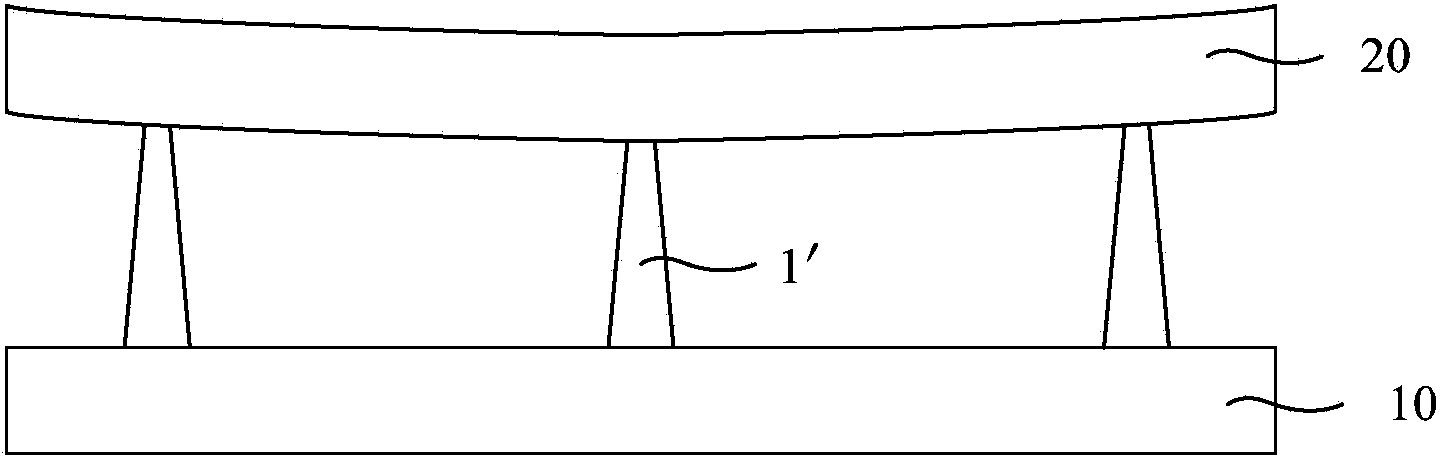

[0038] This embodiment provides a liquid crystal display panel, which includes the substrate in the first embodiment, which solves the problem of inconsistent compression and deformation of spacers supporting the thickness of the liquid crystal display panel box due to the influence of its own gravity, resulting in inconsistent box thickness of the liquid crystal display panel. average problem.

[0039] The substrate may be a color filter substrate of a liquid crystal display panel, or may be an array substrate of a liquid crystal display panel.

Embodiment 3

[0041]This embodiment provides a display device, which adopts the liquid crystal display panel in the second embodiment. Since the cell thickness of the liquid crystal display panel is ensured, the display quality and product yield of the display device are improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com