A device for testing the tensile strength of embedded components of lightweight prefabricated wall panels

A prefabricated wallboard and strength testing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of small load bearing capacity and incompetence of the installation and connection components, and achieve reasonable structure, simple structure, strong and practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

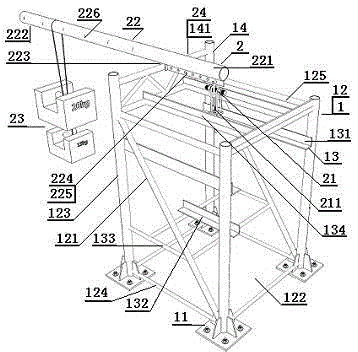

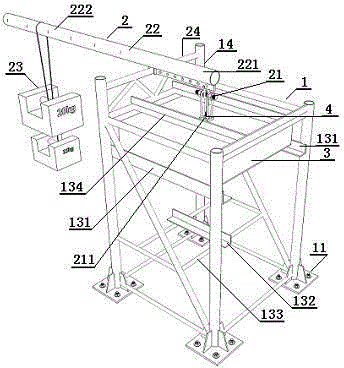

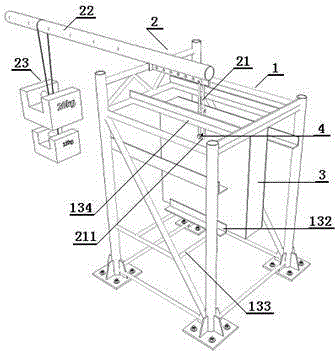

[0021] exist figure 1 , figure 2 with image 3 Among them, the main body of the device for detecting the pull-out strength of pre-embedded components of lightweight prefabricated wall panels is composed of a rigid support 1 and a measurement and force-measuring component 2, which is characterized in that the rigid support 1 is equipped with an upper belt anchor fixed The square frame 12 of the seat 11, the sample limiting member 13 and the weighing bracket 14 arranged on the square frame 12, the measurement and force measuring assembly 2 includes a scale hook 21 with a traction assembly end 211 underneath, and a scale hook 21 with a traction assembly end 211 underneath. The weight end 221, the measuring end 222 and the beam 22 formed by the branch ring 223 arranged at the junction of the weighing end 221 and the measuring end 222, the weighin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com