Angular contact ball bearing dynamic parameter tester

A technology of angular contact ball bearing and dynamic parameters, applied in the direction of mechanical bearing testing, etc., can solve the problem of not being able to test the dynamic parameters of bearings, and achieve the effects of reducing research costs, high positioning accuracy, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

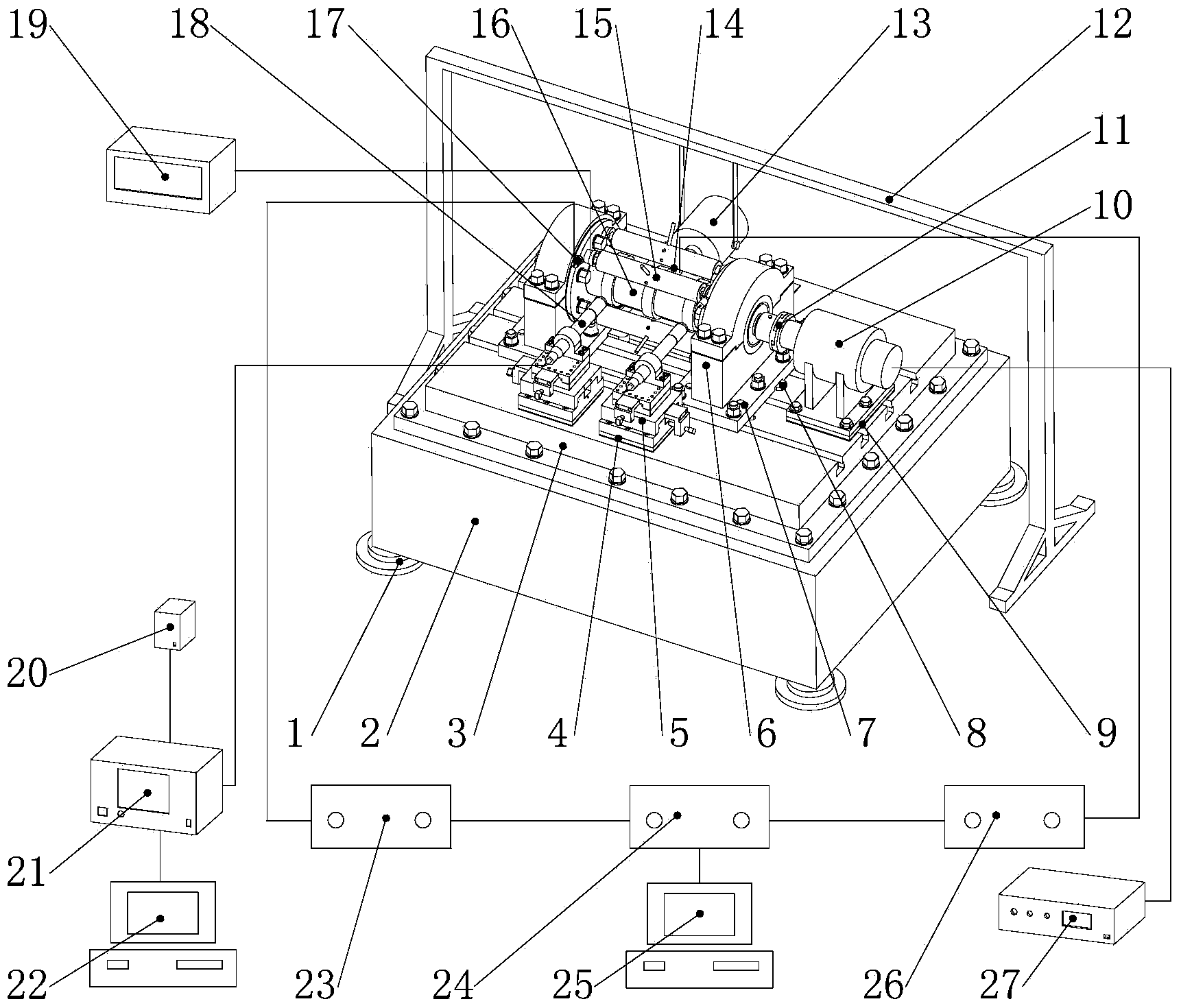

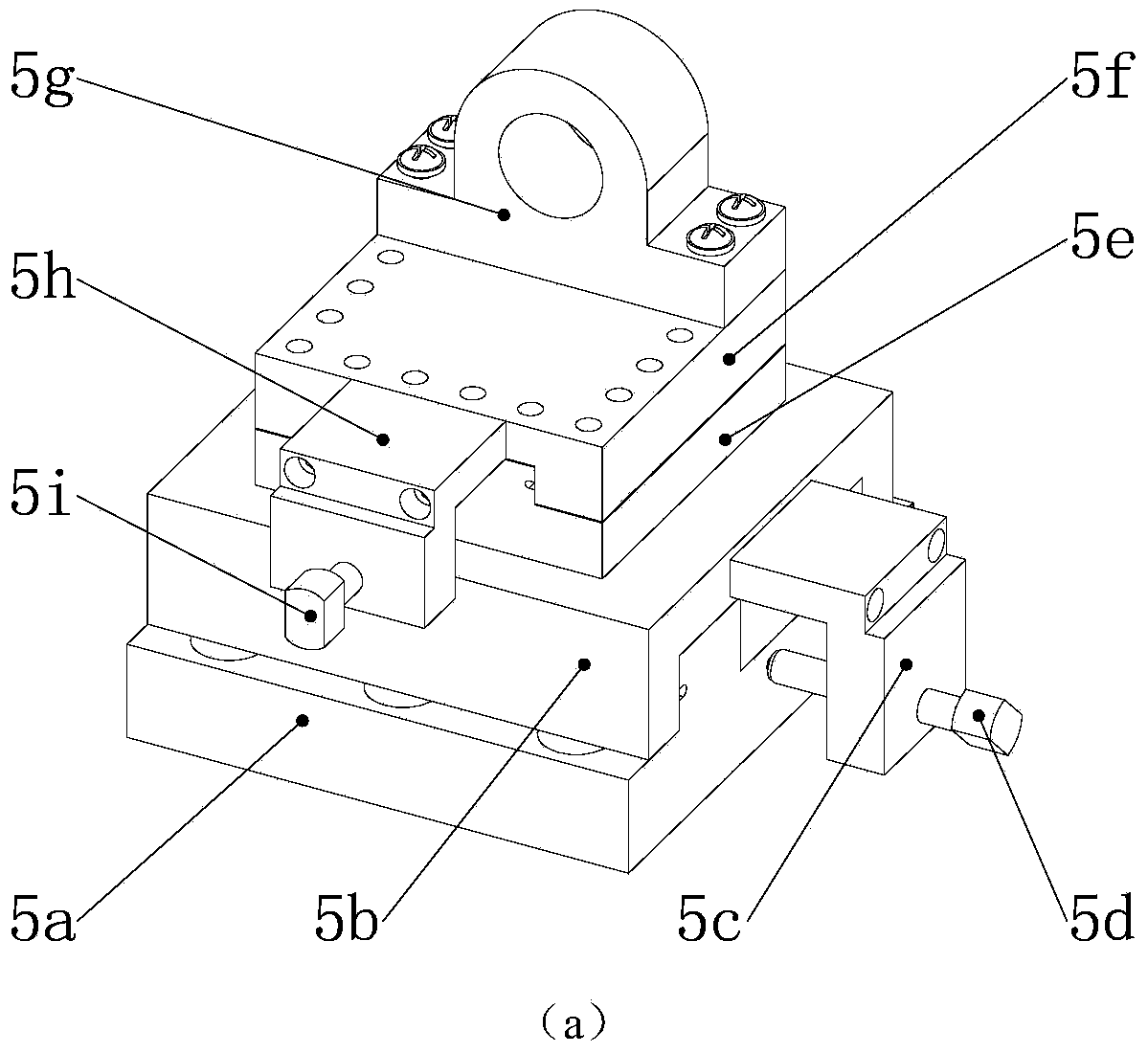

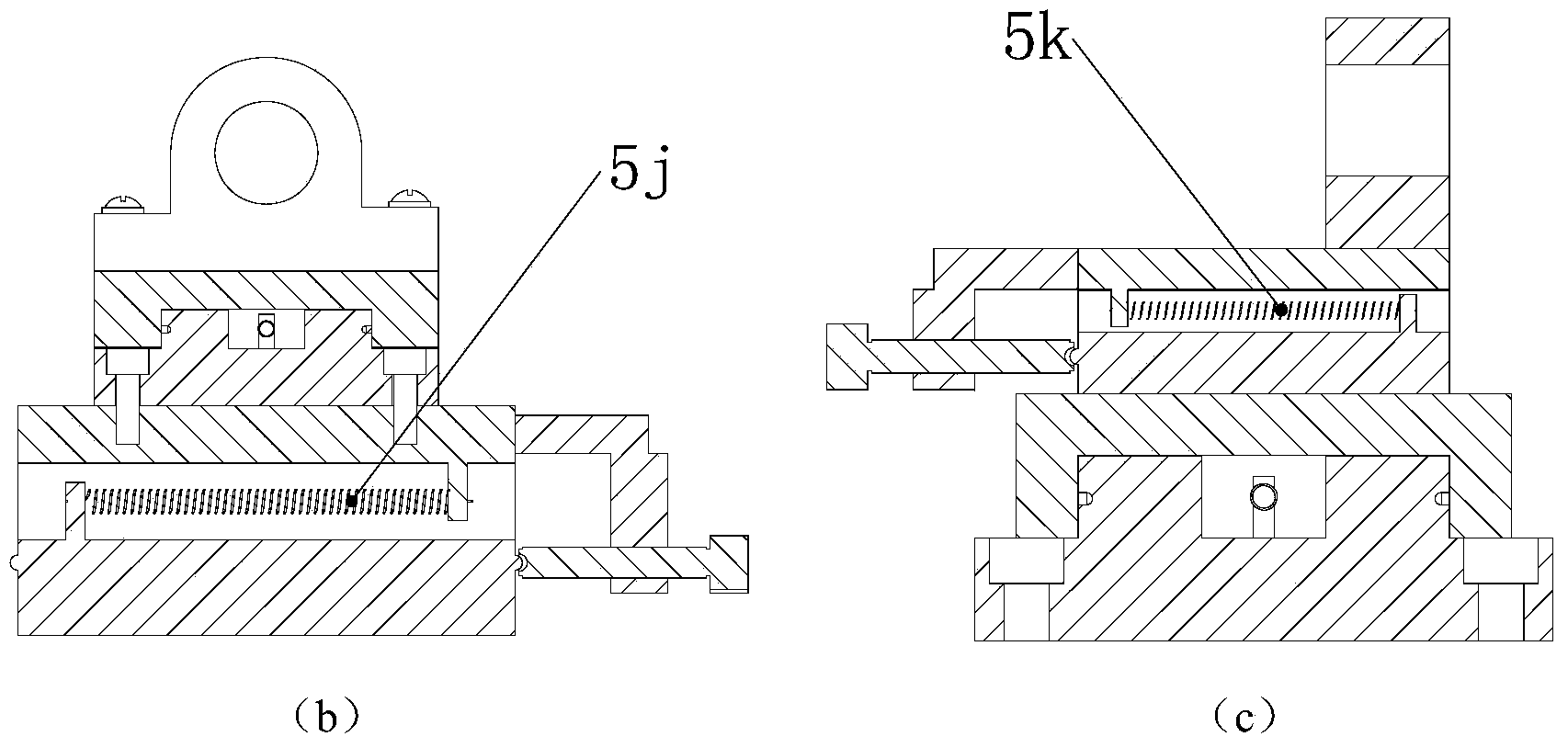

[0031] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , The invention discloses an experimental device for testing dynamic parameters of angular contact ball bearings, which is used for testing the dynamic parameters of angular contact ball bearings with an inner diameter of Φ30 to Φ60 and an outer diameter of Φ55 to Φ110 under different rotational speeds and axial loads. The device includes leveling pad iron 1, experimental platform 2, T-shaped base plate 3, displacement gauge IPN damping plate 4, displacement gauge bracket 5, bearing seat 6, positioning cylindrical pin 7, guide flat key 8, motor IPN damping plate 9. DC motor 10, TS-B type elastic coupling 11, exciter bracket 12, exciter 13, impedance head 14, axial loading mechanism 15, bearing assembly 16, acceleration sensor 17, optical pen 18, CHB Type digital display instrument 19, 24V DC power supply 20, CCS type controller 21, first computer 22, signal conditioner 23, data collector 24, second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com