Motorized spindle rigidity test device

A technology for testing devices and electric spindles, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as the inability to simulate the influence of electric spindles, and achieve easy assembly and maintenance, and a simple and compact device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

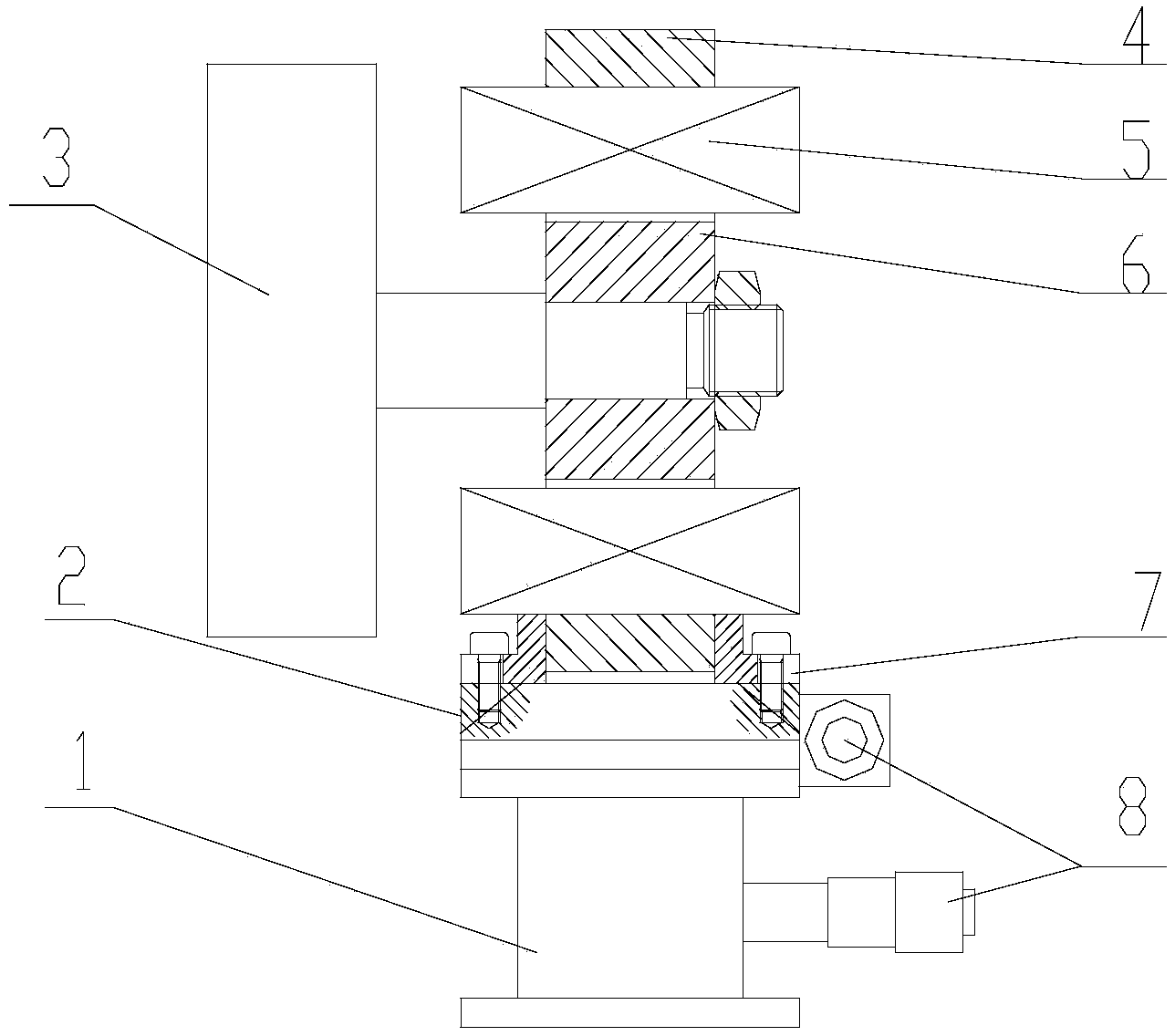

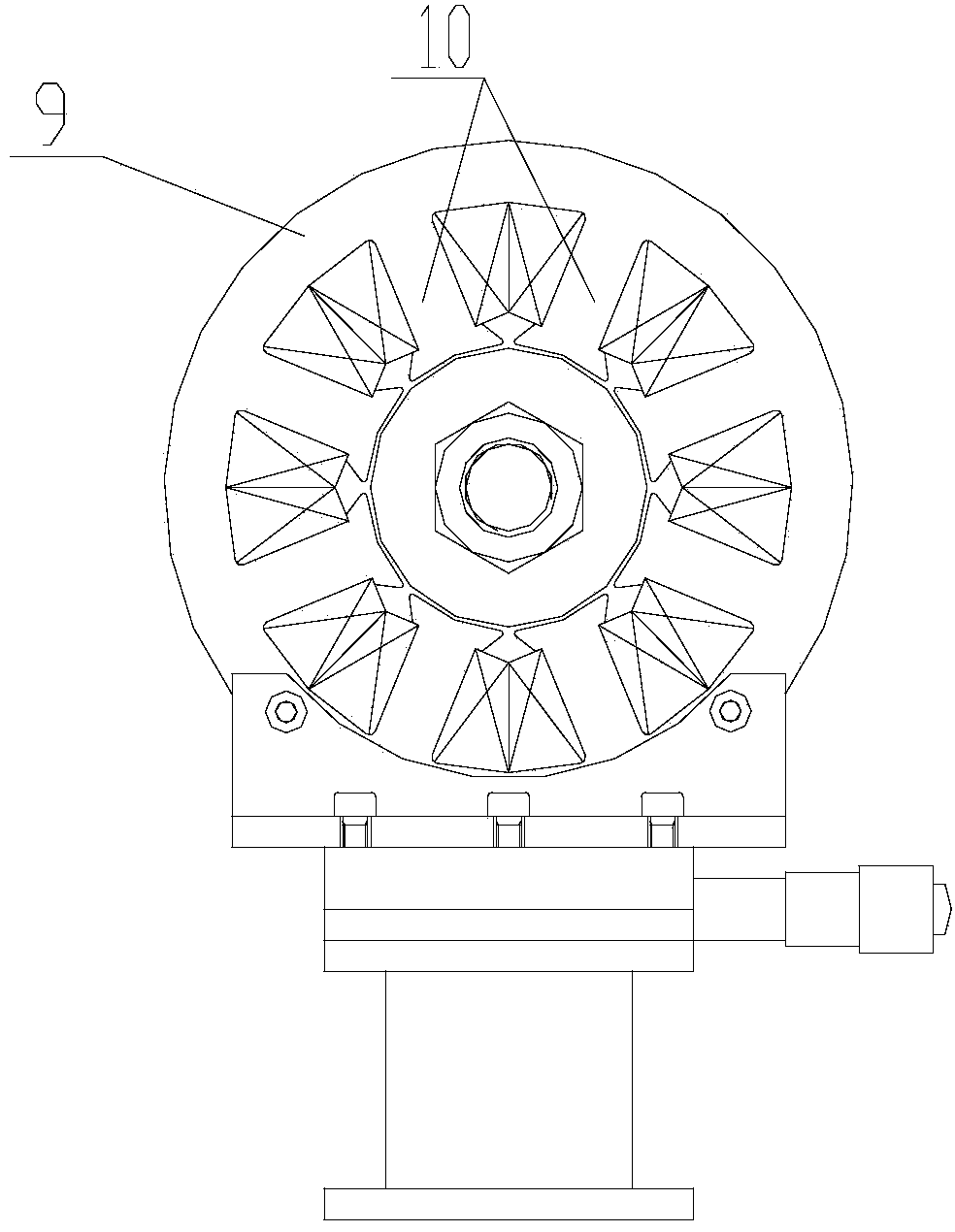

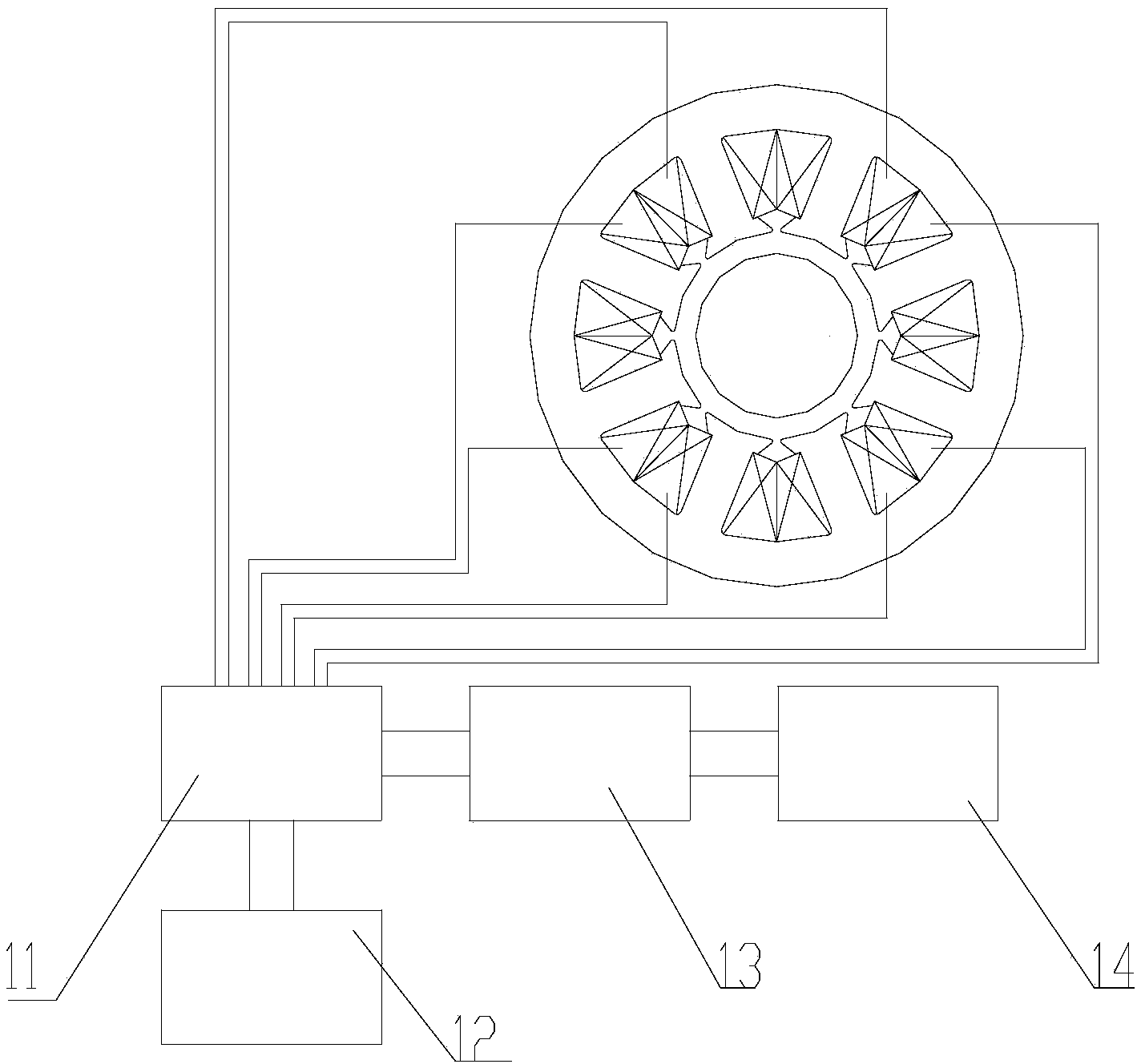

[0018] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 right view of the image 3 It is a schematic diagram of the structure of the circuit control module. As shown in the figure, the electric spindle 3 stiffness testing device in this embodiment includes an electromagnetic loading device and a circuit control module. The electromagnetic loading device includes a magnetically conductive ring 6 coaxially fixedly connected with the electric spindle 3 and a magnetically conductive ring 6 sleeved on the magnetically conductive ring. 6 Outside the excitation device, the circuit control module is used to control the circuit in the excitation device.

[0019] In this embodiment, the excitation device includes an iron core 4 and a coil 5 wound around the iron core for providing magnetic flux to it along the radial direction of the magnetic conduction ring 6, and the iron core 4 includes an outer ring coaxially arranged with the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com