Phosphorite decarburization calcination device

A calcination device and phosphate rock technology, applied in the direction of fluidized bed furnace, furnace, lighting and heating equipment, etc., can solve the problem of no energy saving, low heat recovery rate of high-temperature flue gas and high-temperature phosphate rock clinker, equipment and replacement The heat method is outdated and other problems, and the effect of high phosphorus recovery rate is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

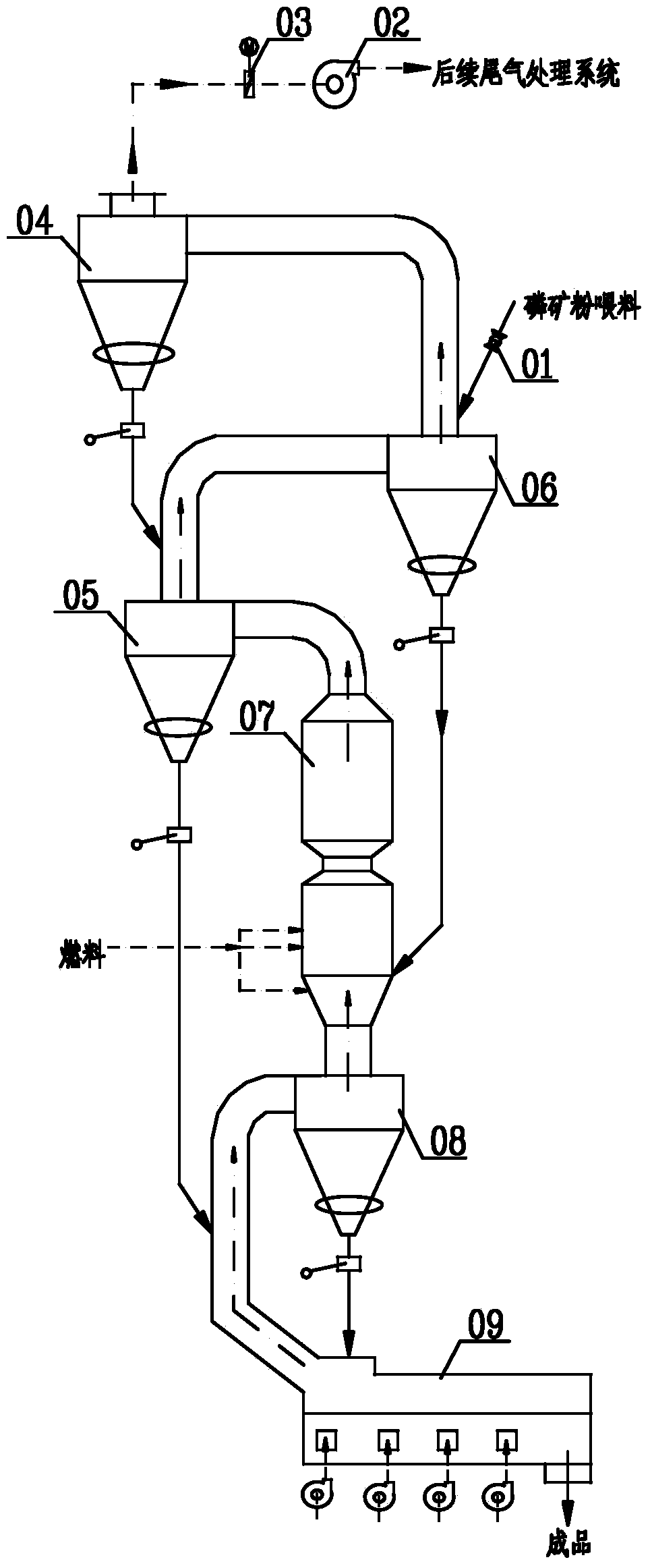

[0039] Such as figure 1 As shown, the solid line with arrows in the figure indicates the material flow, and the dotted line with arrows indicates dusty gas or gas-solid mixture. A decarbonization and calcination device for phosphate rock, including a flue gas heat recovery and phosphate rock powder preheating section, a phosphate rock powder fluidized calcination decomposition section, and a phosphate rock clinker cooling and heat recovery section connected in sequence, flue gas heat recovery and phosphorus The mineral powder preheating section is composed of connected three-stage gas-solid separators, the fluidized calcination and decomposition section of phosphate rock powder is a fluidized calciner, and the phosphate rock clinker cooling and heat recovery section is composed of connected low-speed convective heat exchangers It is composed of a first-stage gas-solid separator.

[0040] 1. High temperature flue gas heat recovery and phosphate rock powder preheating section: ...

Embodiment 2

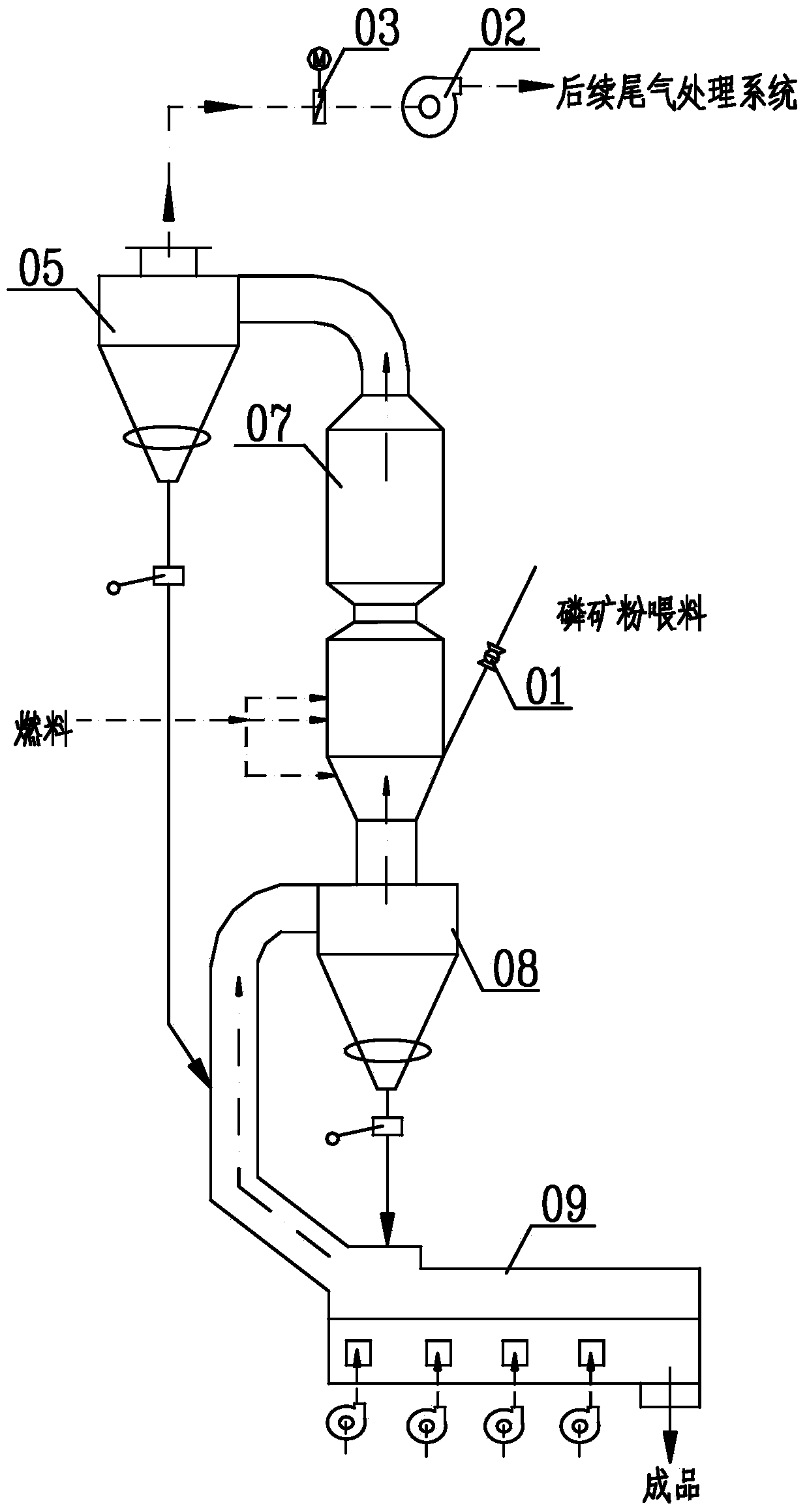

[0050] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1, the difference being that the flue gas heat recovery and phosphate rock powder preheating section is composed of a first-stage gas-solid separator. At this time, the phosphate rock powder raw material does not undergo flue gas heat recovery and The phosphate rock powder is preheated in the preheating section, and is directly put into the fluidized calciner 7 for pre-calcination, but the heat of the high-temperature phosphate rock clinker after calcination is recovered through cooling of the phosphate rock clinker and heat recovery.

Embodiment 3

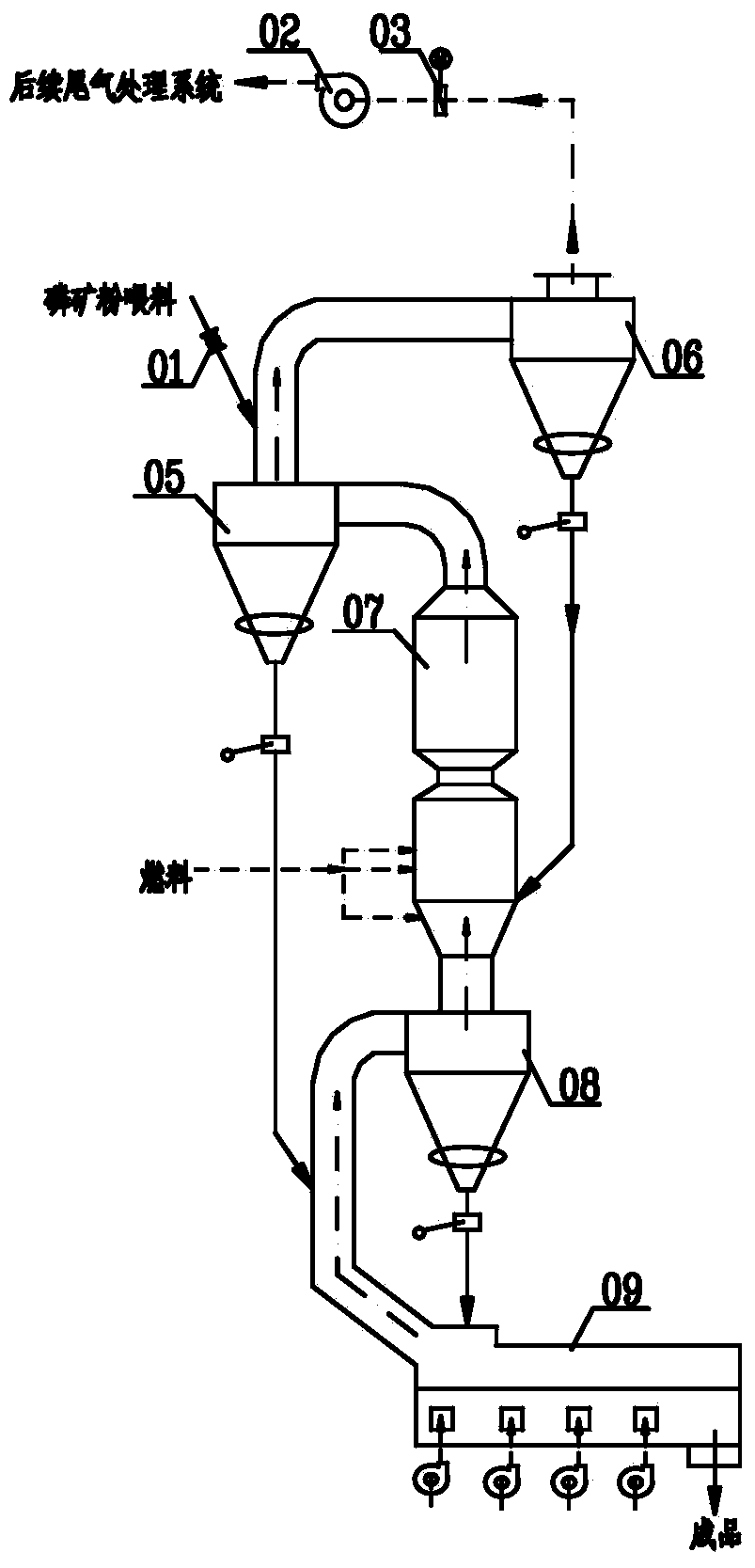

[0052] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that the flue gas heat recovery and phosphate rock powder preheating section is composed of two-stage gas-solid separators, and the phosphate rock powder raw material is only passed through flue gas heat recovery and rock phosphate powder preheating section. Preheating of primary suspension downstream heat exchange in the preheating section of phosphate rock powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com