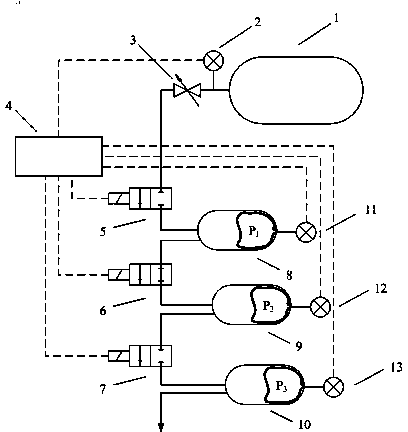

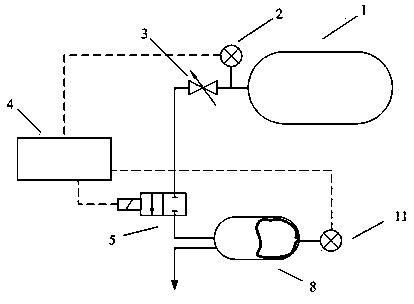

Constant pressure high-pressure gas decompression system

A high-pressure gas, high-pressure gas storage tank technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as reducing system energy utilization, gas energy loss, gas energy loss, etc., to increase Gas internal energy, reducing energy loss, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The high-pressure gas storage tank 1 is high-pressure gas. At the initial setting, the gas pressure in the high-pressure gas storage tank 1 is 30Mpa. The gas pressure is P 1 =10MPa, P 2 =4MPa, P3 =1MPa, the gas pressure after decompression by the first stage decompression system is 10-11MPa, the gas pressure after decompression by the second stage decompression system is 4-4.5MPa, after decompression by the first stage decompression system The gas pressure is 1-1.2MPa. When the gas pressure in the high-pressure gas storage tank 1 is higher than 10MPa, the gas entering the first-stage decompression system from the high-pressure gas storage tank 1 expands in the first accumulator 5 and pushes The air bag of the first accumulator 5 shrinks, reducing the pressure to 10-11MPa, and the gas decompressed by the first-stage decompression system enters the second accumulator 6 of the second-stage decompression system to expand and push The air bag of the second accumulator 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com