U-shaped well hydraulic jet fracturing method

A hydraulic jet, U-shaped technology, applied in earth-moving drilling, wellbore/well components, production fluids, etc., can solve the problems of aggravating sand stuck pipe string, sand stuck pipe string, large fluid flow resistance, etc., reaching the application range Wide and avoid the effect of oil pipe sand stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

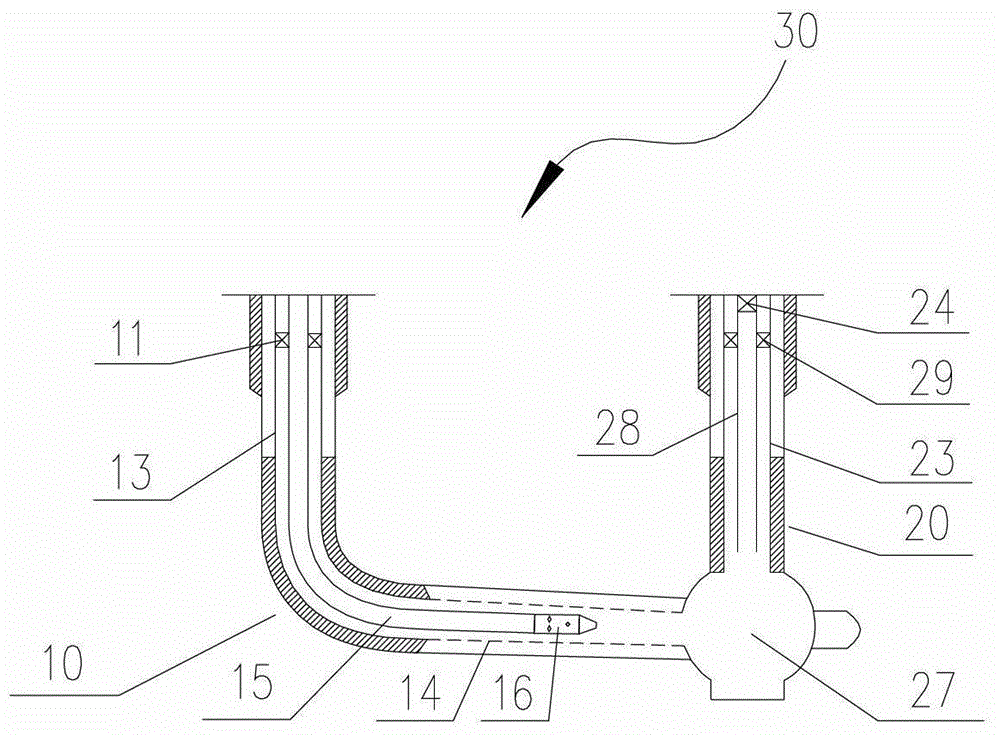

[0024] Such as figure 2 As shown, the U-shaped well 30 includes a horizontal well 10 and a diameter 20 , and the target end of the horizontal section of the horizontal well 10 communicates with the vertical well 20 to form a vertical well cave 27 .

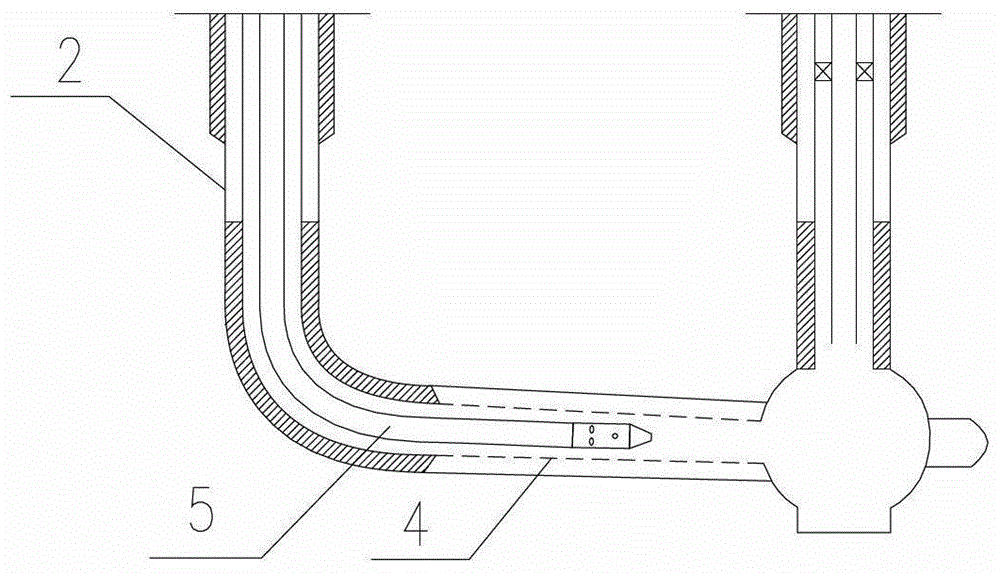

[0025] The following is based on Figure 2-5 Describe the hydrojet pressure process of a U-shaped well. Such as figure 2 As shown, after the horizontal well 10 is completed through the screen 14, the casing 13 is run into the wellbore. Then, the oil pipe 15 with the spray gun 16 is lowered into the casing pipe 13 until the spray gun 16 reaches the position to be fractured. A casing 23 is also run in the vertical well 20 . Finally, a casing gate 11 is set in the annular space between the tubing 15 and the casing 13 of the horizontal well 10 , and a drainage gate 24 is set in the casing 23 of the vertical well 20 . In a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com