Pile body longitudinal multipoint grouting device

A grouting device and longitudinal technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of many sections, poor controllability of grouting quality, large engineering volume and difficulty in work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

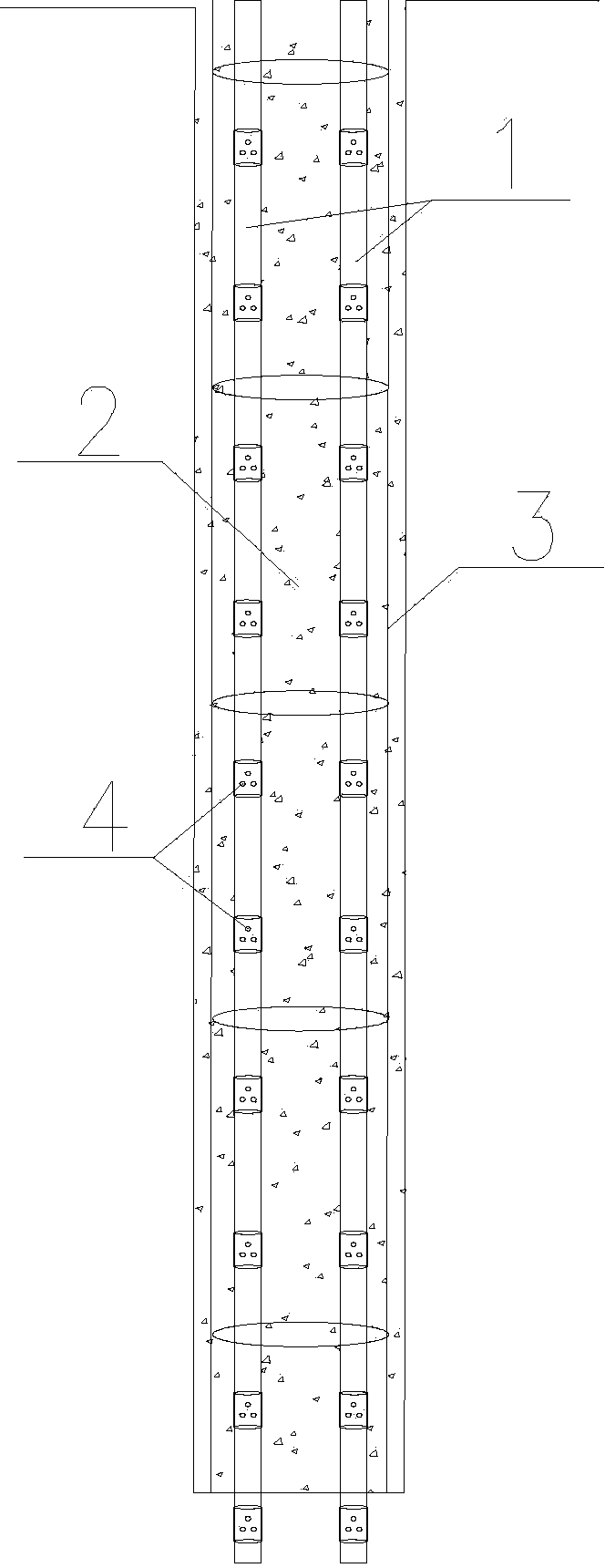

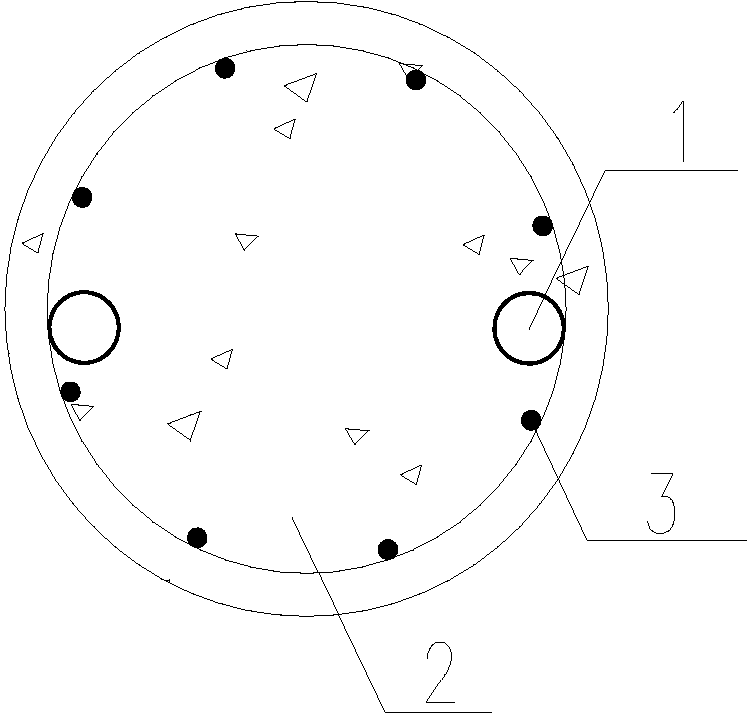

[0017] Such as figure 1 , figure 2 As shown, the pre-embedded grouting conduit 1 is a steel pipe coaxially attached to the inner side of the reinforcement cage 3 of the cast-in-place pile 2. The inner diameter of the steel pipe is not smaller than the diameter of the grouting core pipe, and usually the inner diameter of the steel pipe is greater than 60mm. The top elevation of the grouting conduit 1 is about 200mm higher than the ground elevation, and the bottom elevation of the pipe is 200-500mm lower than the end elevation of the cast-in-place pile 2. The grouting conduit is provided with grouting holes 4 at intervals of 1 to 2 m in the longitudinal direction.

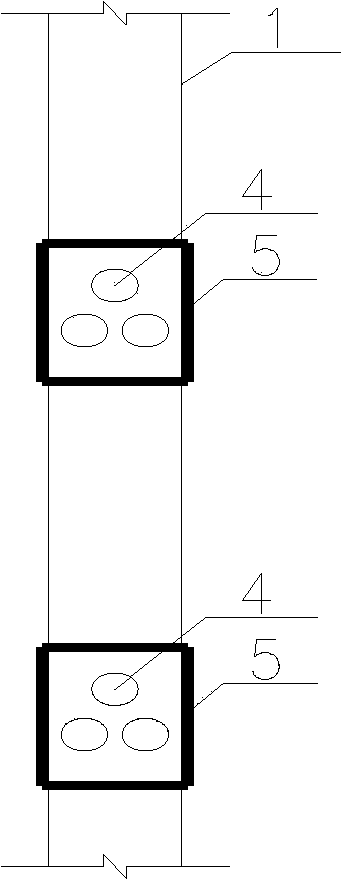

[0018] Such as image 3 As shown, the grouting holes 4 are arranged symmetrically along the circumference of the pipe, and can be arranged in a quincunx shape. The outside of the grouting hole can adopt the mode of wrapping rubber skin 5, realizes the protection to hole.

[0019] Such as Figure 4 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com