Real-time monitoring method and monitoring system for pavement thickness of high-grade highway

A real-time monitoring and high-level technology, which is applied in the field of monitoring system and paving thickness of pavement structure layer, can solve the problems of measuring laser scanner, cannot be high-precision, cannot intuitively and accurately indicate the absolute position of the road surface, etc., to reduce one-sidedness , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

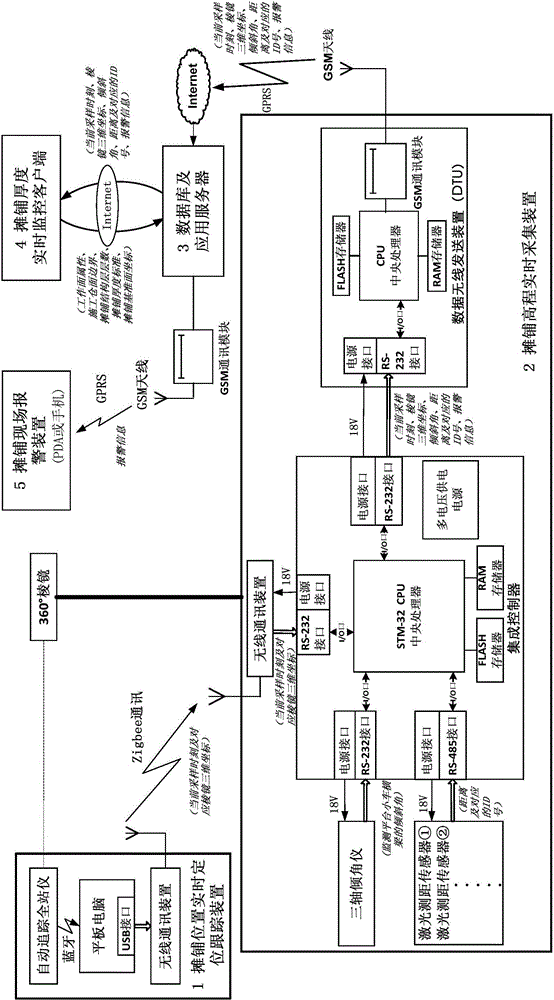

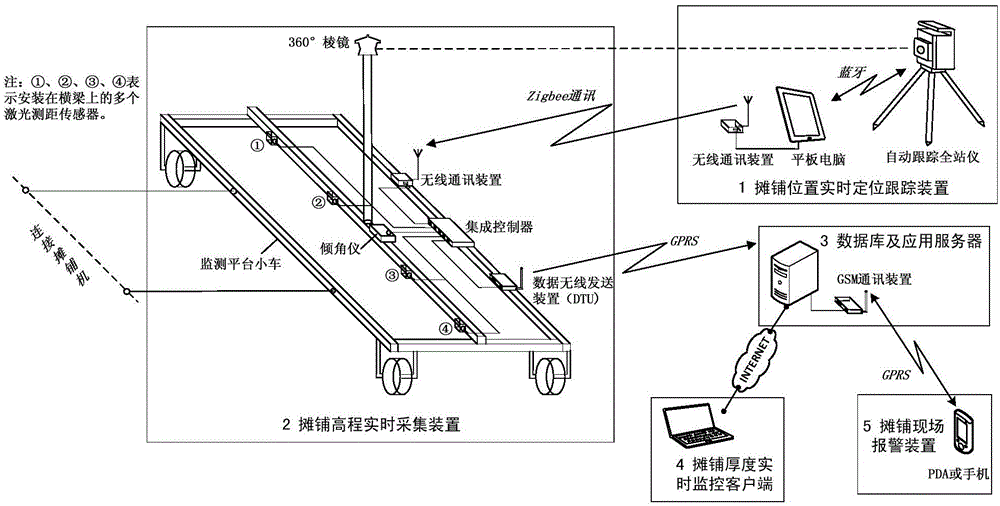

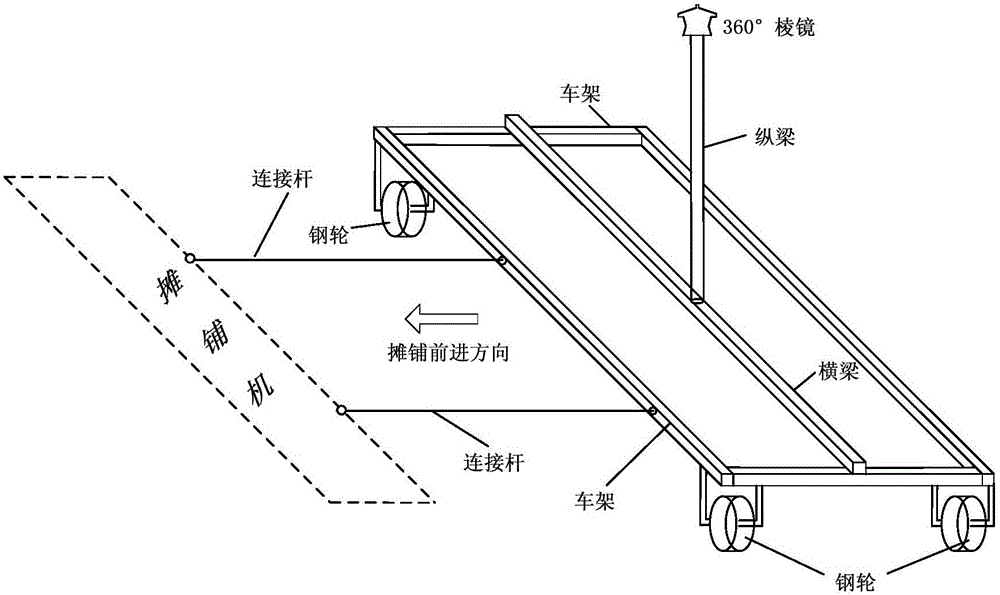

[0029] See the composition structure of this system figure 1 , Including: real-time positioning and tracking device of paving position, real-time acquisition device of paving elevation, database and application server, real-time monitoring client of paving thickness, and five parts of paving scene alarm device.

[0030] Real-time positioning and tracking devices for paving positions include automatic tracking total stations, tablet computers, and wireless communication devices. The automatic tracking total station is installed near the paving site, and the position of the erection point can be measured through the rear intersection according to the known point coordinates (by measuring the distance and angle to at least two known coordinate points, and inverting the coordinates of the station). The method is determined. It locates and tracks the 360° prism in the paving elevation real-time acquisition device at a sufficiently small time interval, and obtains the three-dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com