Linear evaporation source device

A technology of linear evaporation source and detection device, applied in vacuum evaporation plating, ion implantation plating, metal material coating process, etc., can solve problems such as deterioration, nozzle clogging, film thickness uniformity, etc. Control the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

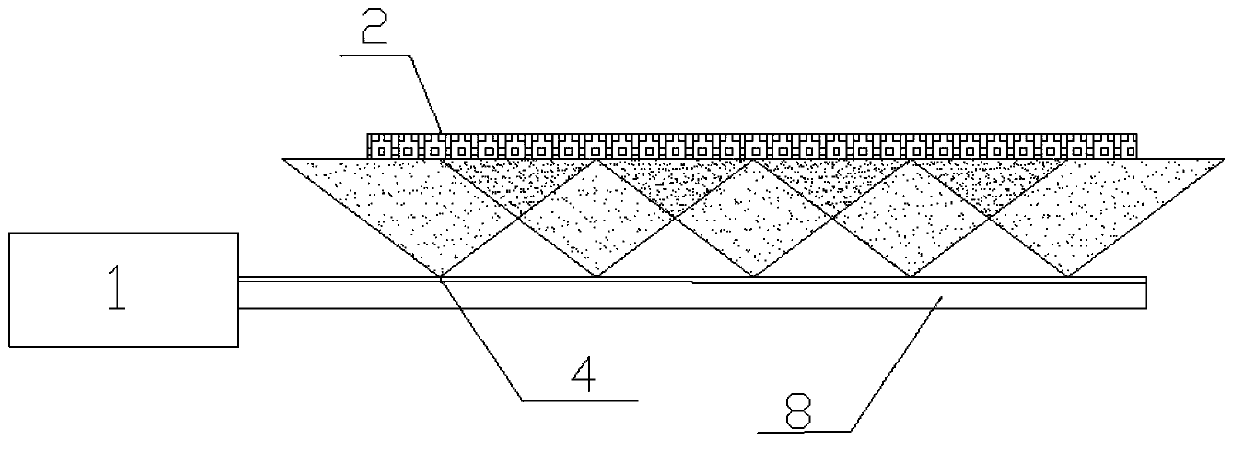

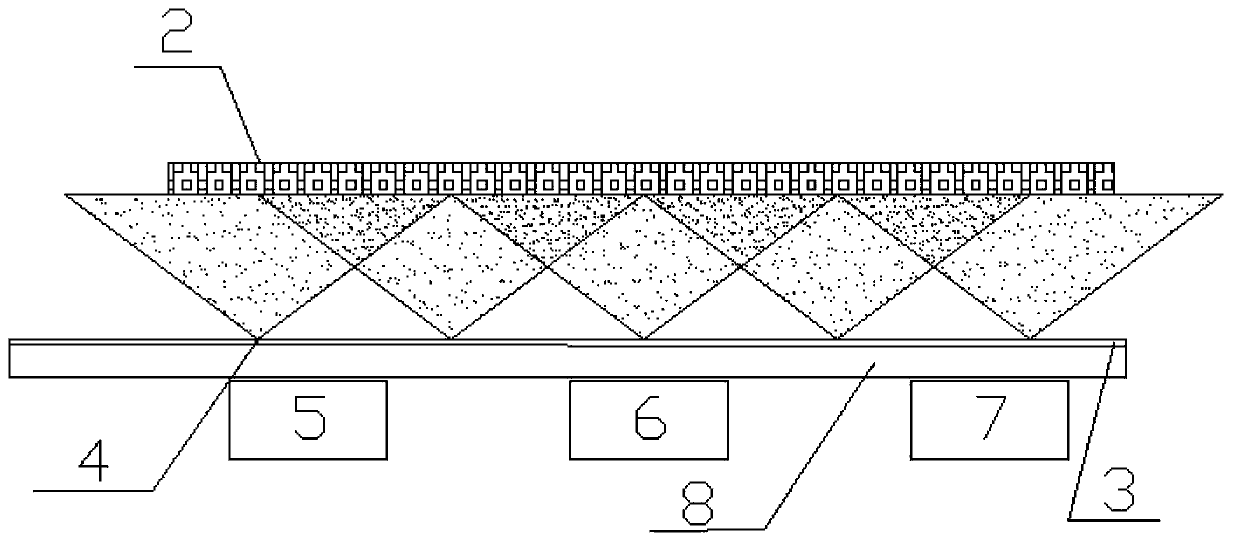

[0019] A linear evaporation source device such as figure 2 As shown, it is used to deposit a thin film on a glass substrate 2, including: a material chamber 8, a nozzle cover 3 and a heating source 5, 6, 7, wherein the nozzle cover 3 is located above the material chamber 8 and has a plurality of nozzles 4 , the nozzle 4 is hole-shaped and evenly distributed on the nozzle cover 3; the heating sources 5, 6, and 7 are evenly distributed under the material chamber 8, and each heating source is a heating wire, between two adjacent heating wires The spacing is 1 / 2 of the diameter of the heating wire, and each heating wire is connected to an independent voltage source and controlled by an independent operating system. The operator can adjust the output voltage of the voltage source through the operating system.

[0020] In actual operation, the uniformity of the film is detected by performing a film thickness test on the prepared film. When it is found that the film thickness in a ...

Embodiment 2

[0022] The technical content in this embodiment that is the same as or similar to that in Embodiment 1 will not be repeated here.

[0023] Different from Embodiment 1, in this embodiment, the nozzles 4 are slit-shaped, evenly distributed on the nozzle cover 3 , and protrude from the nozzle cover 3 . Each heating source is a heating wire array, and the distance between two adjacent heating sources is 1 / 2 of the width of the heating wire array. Each heating source is connected to an independent voltage source and is controlled by an independent operating system. The operator can The output voltage of the voltage source is adjusted by the operating system.

[0024] In this embodiment, the linear evaporation source device also includes three crystal oscillator sensors, and the crystal oscillator sensors correspond to the heating sources 5, 6, and 7 respectively, and are arranged above the nozzle cover 3 near the glass substrate 2 for real-time monitoring of the three crystal oscil...

Embodiment 3

[0026] The same or similar technical content as that of Embodiment 2 in this embodiment will not be repeated here.

[0027] Different from Embodiment 2, in this embodiment, the nozzles 4 are in two shapes of holes and slits, which are evenly distributed on the nozzle cover 3 and protrude from the nozzle cover 3 . In addition, the linear evaporation source device also includes three temperature sensors, and the temperature sensors correspond to the heating sources 5 , 6 , and 7 respectively, and are arranged on the inner wall of the material chamber 8 . The operating system of the heating source is electrically connected to the corresponding crystal oscillator sensor and temperature sensor, and automatically adjusts the voltage applied to the corresponding heating source according to the film thickness fed back by the crystal oscillator sensor and the temperature fed back by the temperature sensor.

[0028] The technical solution of this embodiment can automatically adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com