Non-ionic compound gas hydrate anti-agglomerant

A gas hydrate and composite technology, which is applied in the direction of drilling composition, gas/liquid distribution and storage, pipeline system, etc., can solve the problems of insignificant anti-polymerization effect, poor biodegradability, high price, etc., and achieve good Application prospect, low addition amount, high supercooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example provides a nonionic composite gas hydrate antipolymerization agent, which is composed of alkyl glycoside nonionic surfactant APG1214 and polyol type nonionic surfactant Span20 in a mass ratio of 1:1 Than obtained by mixing.

[0045] Apply the above-mentioned non-ionic composite gas hydrate antipolymerization agent to the oil-gas-water three-phase mixed transportation system with a water content of 10% (calculated based on the sum of the volumes of water and oil), and analyze the The use effect of non-ionic composite gas hydrate antipolymerization agent was evaluated.

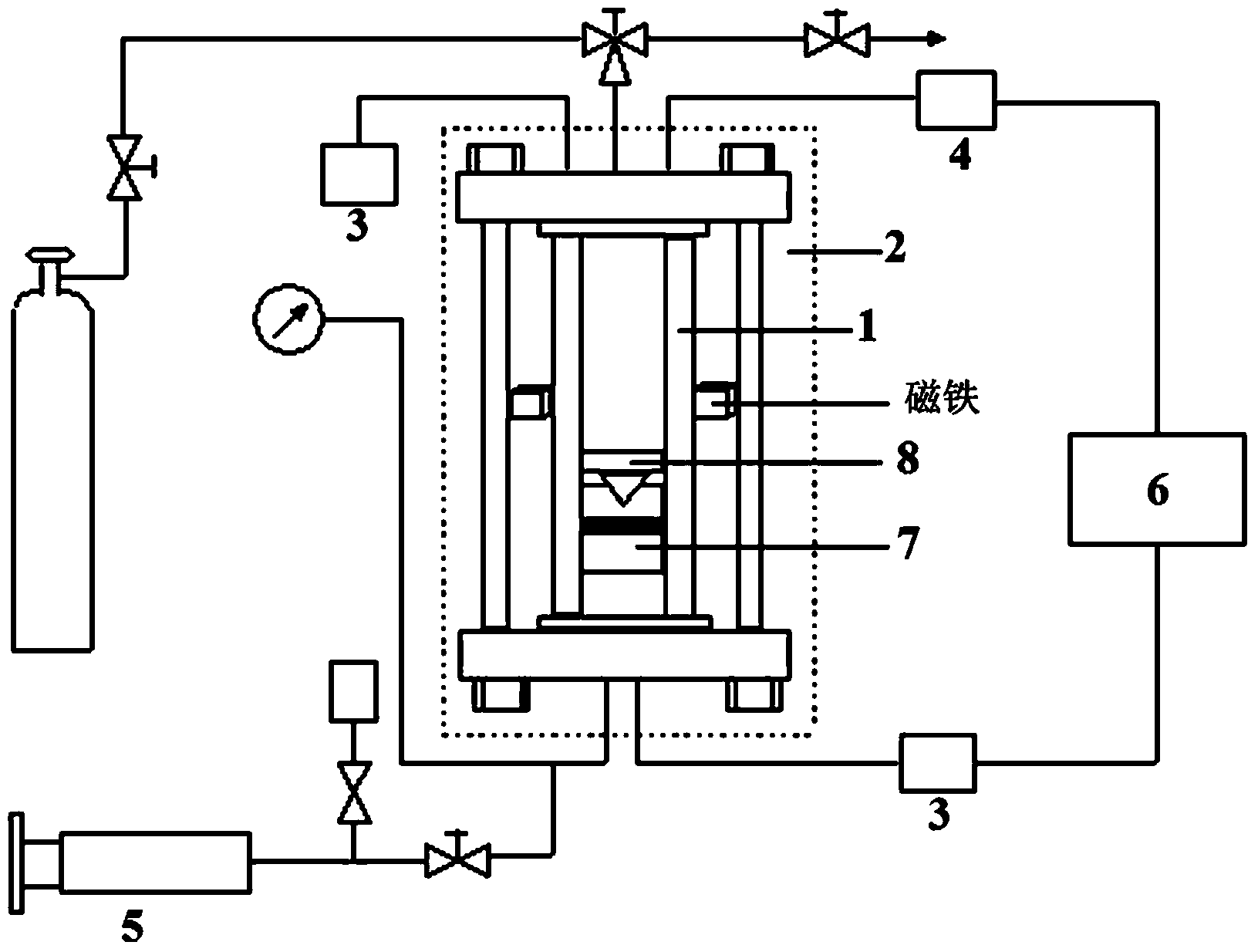

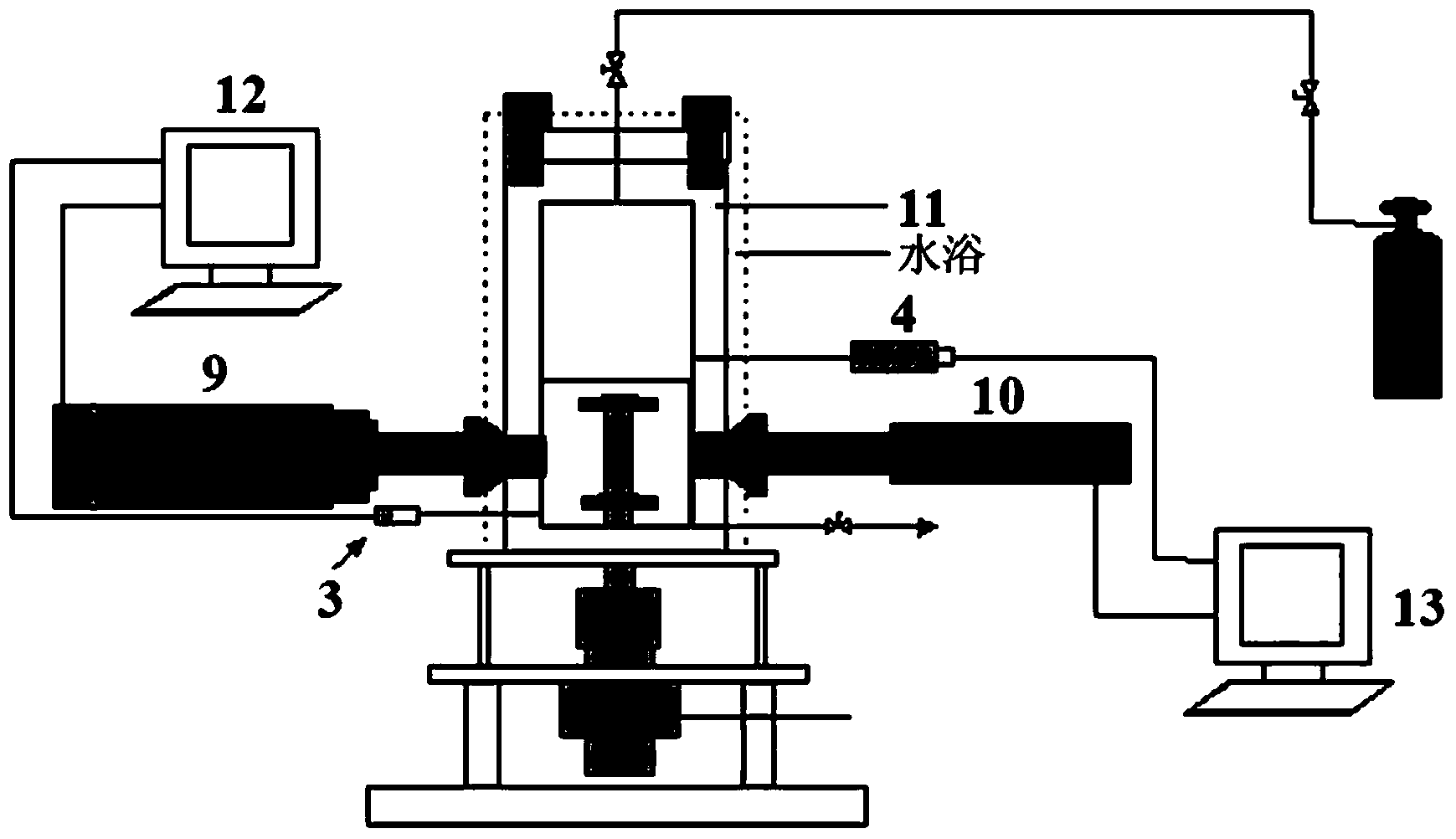

[0046] In this example, a high-pressure fully transparent sapphire reactor is used for the application evaluation experiment. The structure of the high-pressure fully transparent sapphire reactor is as follows figure 1 shown. The reactor is a common equipment for evaluating the inhibitory effect of gas hydrate antipolymerization agent, mainly including high-pressure sapphire reactor body 1,...

Embodiment 2

[0059] This embodiment provides a nonionic composite gas hydrate antipolymerization agent, which is composed of alkyl glycoside nonionic surfactant APG1214 and polyol type nonionic surfactant Span20 in a mass ratio of 0.25:1 Than obtained by mixing.

[0060] In this example, the high-pressure fully transparent sapphire reactor described in Example 1 is used to conduct an application evaluation experiment, and the specific experimental process is as described in Example 1.

[0061] In this example, the oil-water system in the reactor is composed of 1.5mL of deionized water and 13.5mL of -20# diesel oil, that is, a mixed transportation system with a water content of 10% (calculated based on the sum of the volumes of water and oil) , the amount of antipolymerization agent added in this embodiment is 3.0% of the water mass in the system, and the composition of the gas introduced is shown in Table 1.

[0062] During the whole experiment process of this example, the gas hydrate par...

Embodiment 3

[0064] This example provides a nonionic composite gas hydrate antipolymerization agent, which is composed of alkyl glycoside nonionic surfactant APG1214 and polyol type nonionic surfactant Span20 in a mass ratio of 0.5:1 Than obtained by mixing.

[0065] In this example, the high-pressure fully transparent sapphire reactor described in Example 1 is used to conduct an application evaluation experiment, and the specific experimental process is as described in Example 1.

[0066] In this example, the oil-water system in the reactor is composed of 1.5mL of deionized water and 13.5mL of -20# diesel oil, that is, a mixed transportation system with a water content of 10% (calculated based on the sum of the volumes of water and oil) , the amount of antipolymerization agent added in this embodiment is 3.0% of the water mass in the system, and the composition of the gas introduced is shown in Table 1.

[0067] During the whole experiment process of this example, the gas hydrate particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com