Multifunctional general tool for curved surface coating

A multi-functional, curved surface technology, applied to labels, packaging, labeling machines, etc., can solve problems such as difficult positioning, color difference, and differences, and achieve the effects of avoiding air bubbles and pinholes, saving production costs, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

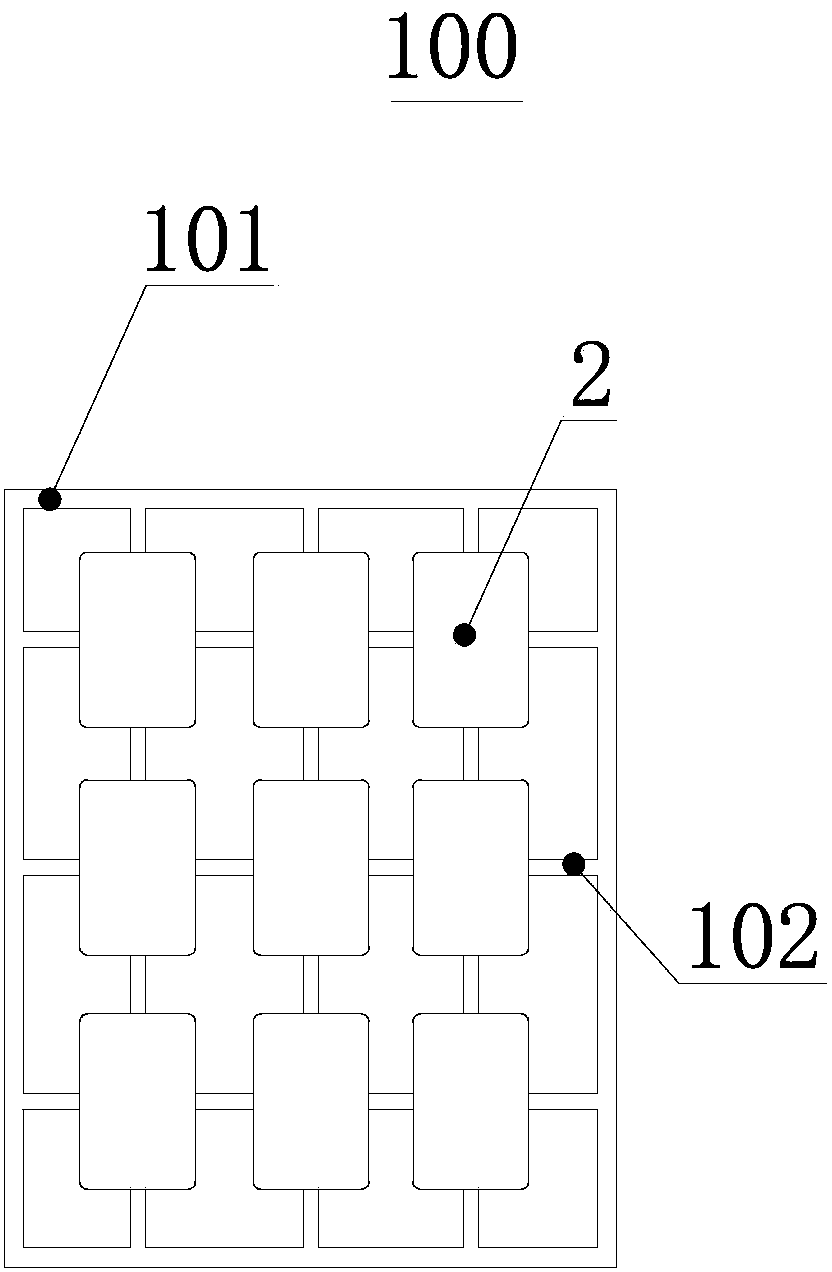

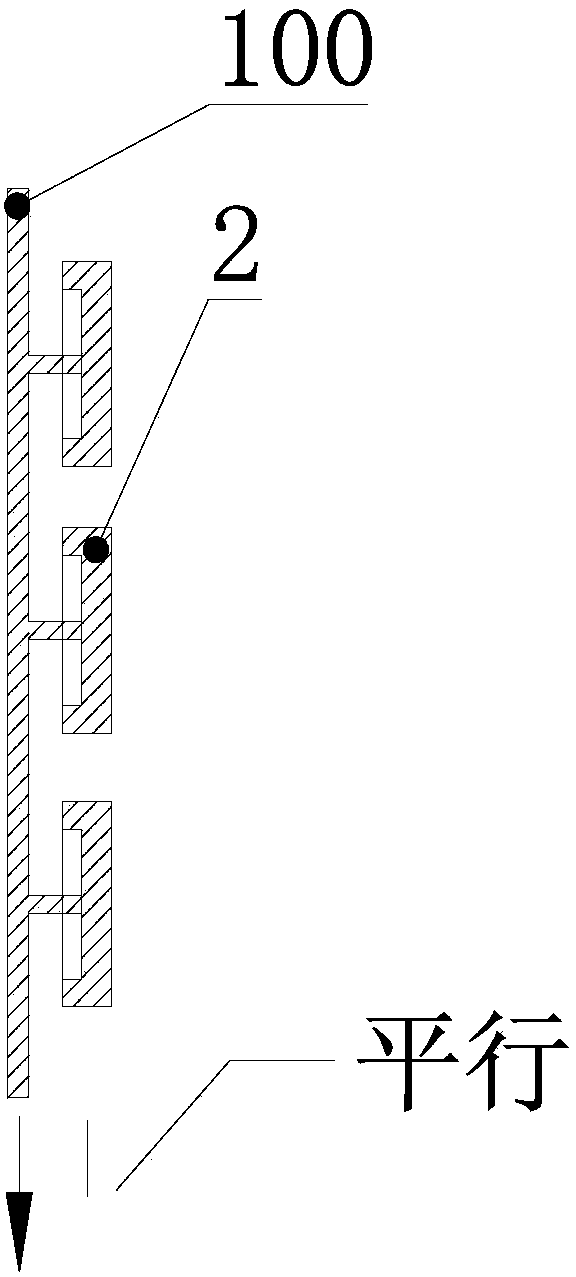

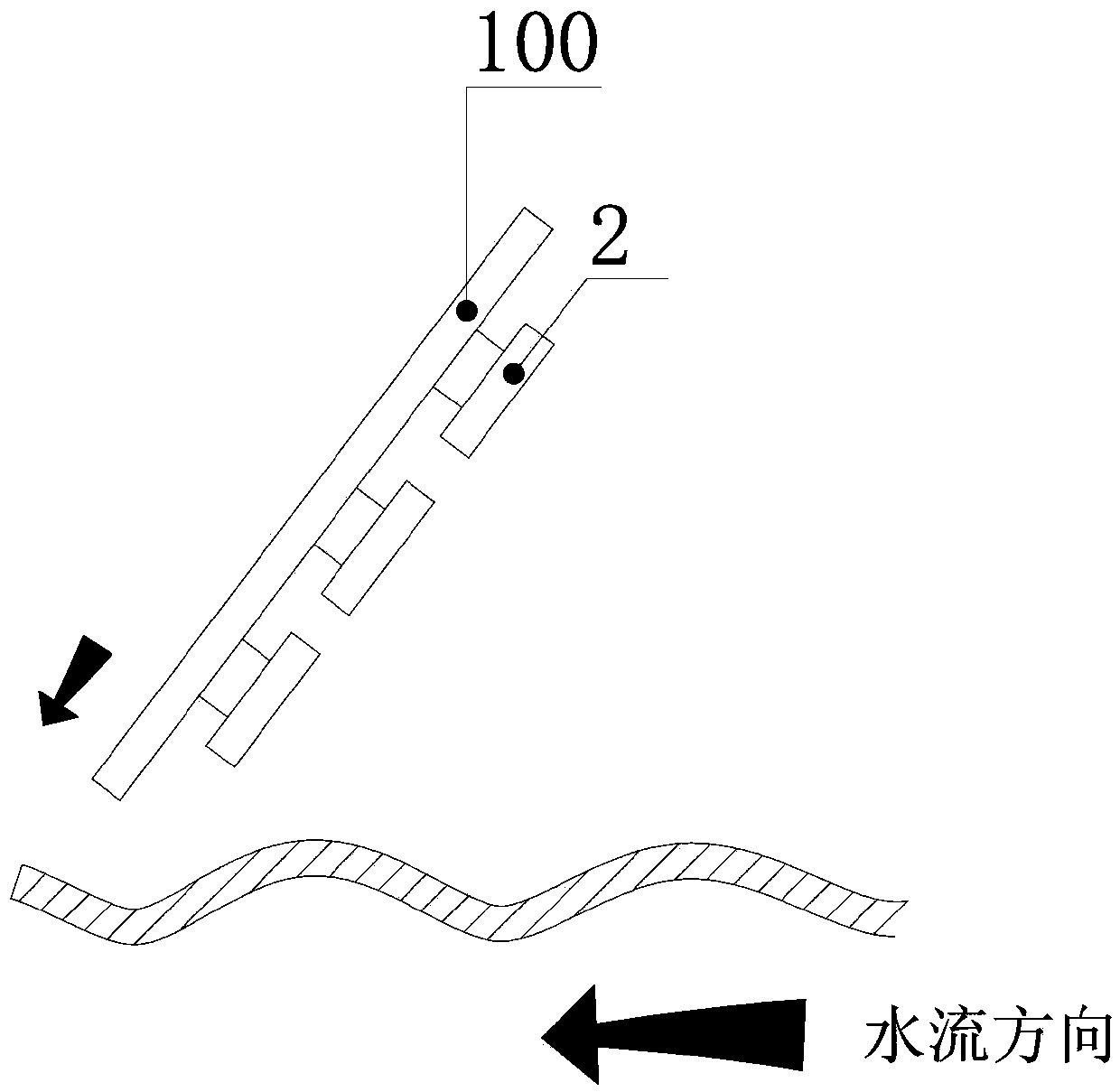

[0053] This embodiment discloses a multifunctional universal jig covered with a curved surface. The multifunctional universal jig includes:

[0054] an umbrella-shaped skeleton mechanism that can expand and contract in the vertical direction and expand and contract in the horizontal direction; and

[0055] A plurality of workpiece fixing mechanisms 204 for grabbing or installing the workpiece 2 are respectively connected to each lower end of the umbrella-shaped skeleton mechanism, and can be adjusted at any angle around the lower end.

[0056] Such as Figure 4 and 6 As shown, the umbrella skeleton mechanism includes a main shaft 201 , a first straight rod 202 and a second straight rod 203 . Wherein, the first straight rod 202 and the second straight rod 203 form a sub-axis, the first straight rod 202 and the main shaft 201 are connected together through a gear structure, one end of the second straight rod 203 is connected with the first straight rod 201, and the other end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com