3D three-dimensional painting production process

A technology for making crafts and three-dimensional pictures, which is applied in decorative art, optics, instruments, etc., and can solve problems such as insufficient three-dimensional sense, weak recognition, dizziness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below in conjunction with accompanying drawing:

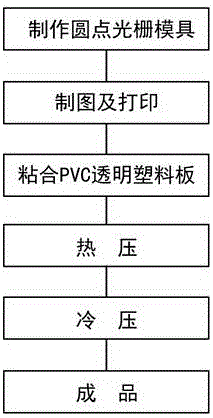

[0014] Such as figure 1 Shown, a kind of 3D three-dimensional painting manufacturing process comprises the following steps:

[0015] (1) Making a dot grating mold: According to whether the final retroreflective sheeting has square-corner round pyramids, cube-corner depressions, or both, the master mold is made first, and the structure surface of the master mold corresponds to the surface of the final retroreflective sheeting. The geometry of the required cube corner elements is then replicated using the technique of nickel plating to make retroreflective sheeting molds that resemble square cubes;

[0016] (2) Drawing and printing: use PSDTO3D software to make images, adjust the resolution of the images to 2400PPI, make 32 images, use PSDTO3D software to merge, and form a complete image after merging, and then print with coated paper Come out, wait for the ink to cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com