Efficient concrete spacer block machine

A concrete and block machine technology, applied in the field of building materials manufacturing, can solve the problems of unadjustable capacity of the distribution box, short service life of the pallet, poor vibration effect, etc., and achieve good vibration effect, long service life and adjustable capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

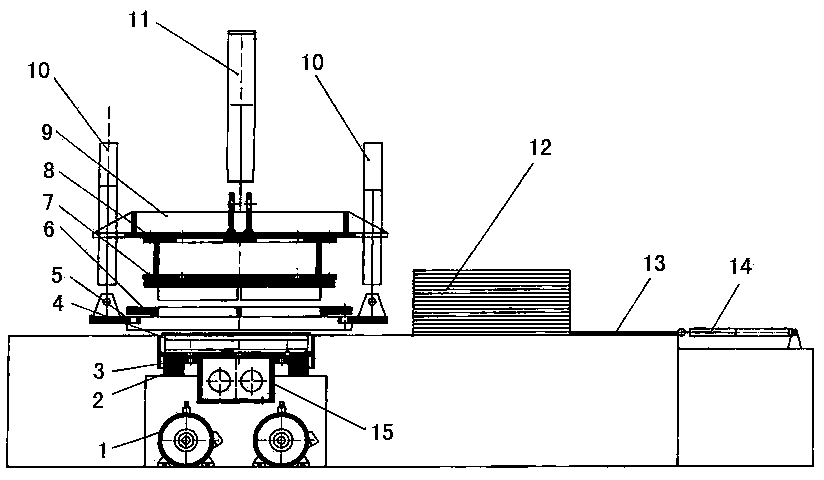

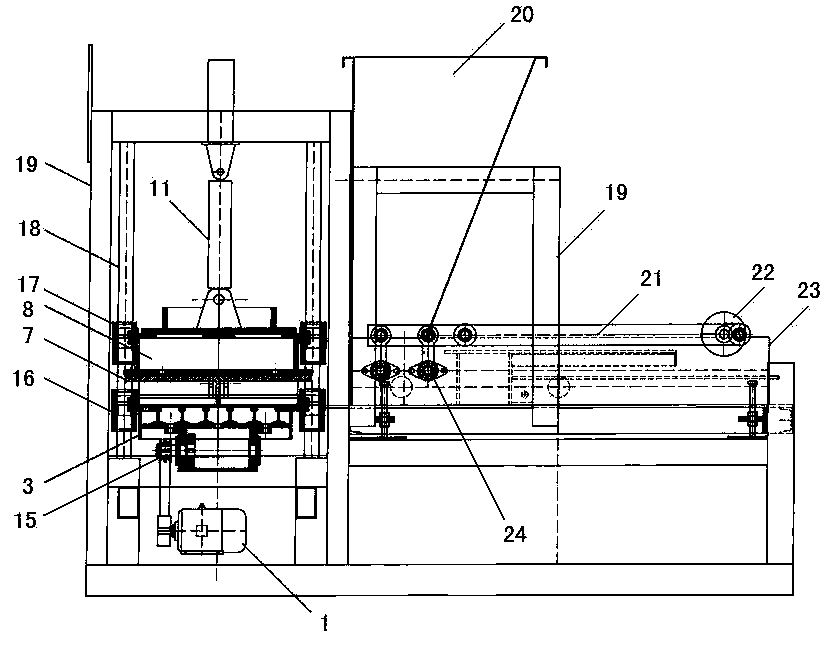

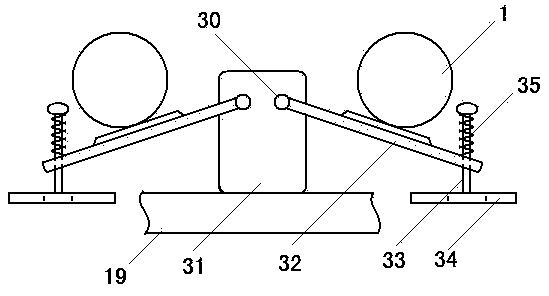

[0024] Such as figure 1 , 2 , 3, 4 shown.

[0025] The forming host includes: the upper mold box 8 and the upper mold 7 are arranged on the lower part of the upper connecting plate 9, the upper connecting plate 9 is connected to the upper hydraulic cylinder 11, and the upper hydraulic cylinder 11 is arranged on the top of the frame 19; the upper hydraulic cylinder 11 can lift / Put down the upper mold box 8 and the upper mold 7, the upper hydraulic cylinder 11 is provided with a pressure control device, the pressure of the upper hydraulic cylinder 11 can be reduced from high pressure (usually set to 6.5-7.5MPa) to low pressure (usually set to 0 -0.5MPa); the pressure control device includes a pressure pump and a solenoid valve controlled by a computer; four upper sliding sleeves 17 are set at the four corners of the upper mold box 8 and the upper mold 7, and the upper sliding sleeves 17 are set on the sliding rod 18; the lower mold 6 Placed in the lower mold frame 5, the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com