PDM (Positive Displacement Motor) drill cleaning system

A screw drilling tool and cleaning device technology, which is applied to cleaning methods and tools, cleaning methods using liquid, filtration and separation, etc., can solve the problems that the inner cavity parts cannot be cleaned, affect the maintenance work, and the cleaning efficiency is low, so as to achieve saving Reduce the labor intensity of human resources and employees, improve the HSE management level, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

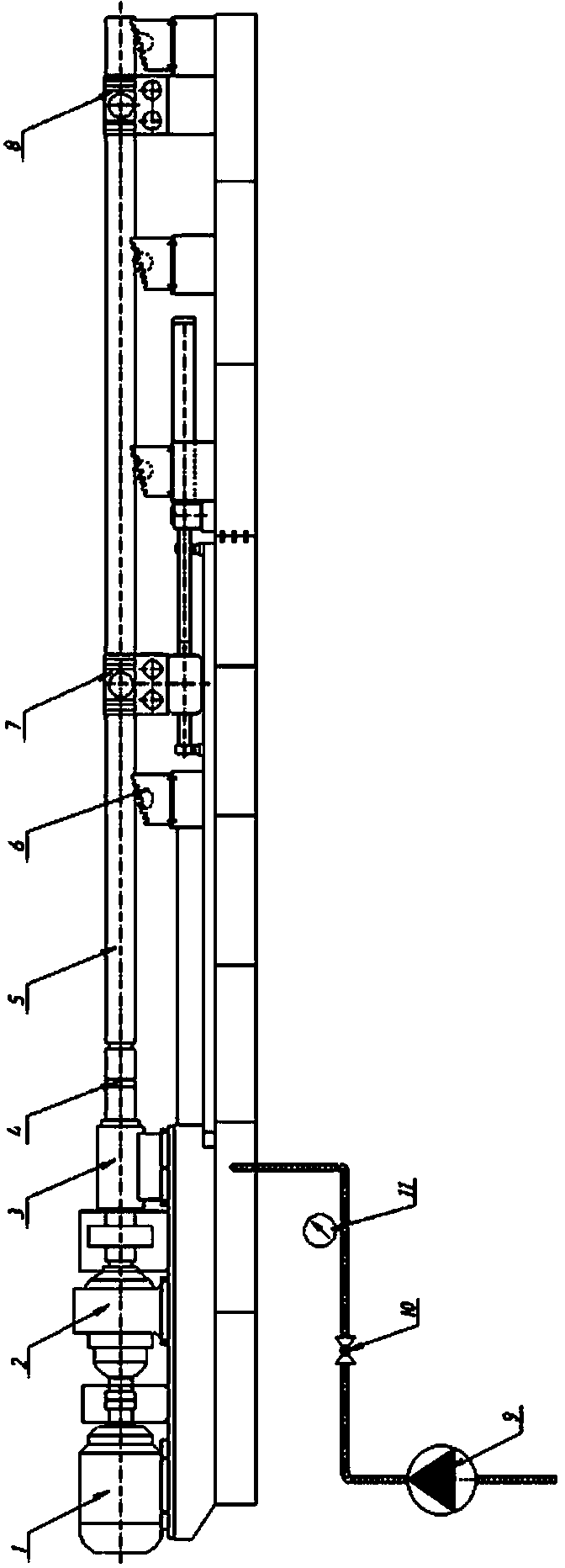

[0017] In order to further disclose the technical solution of the present invention, the following will be described in detail in conjunction with the accompanying drawings in the description:

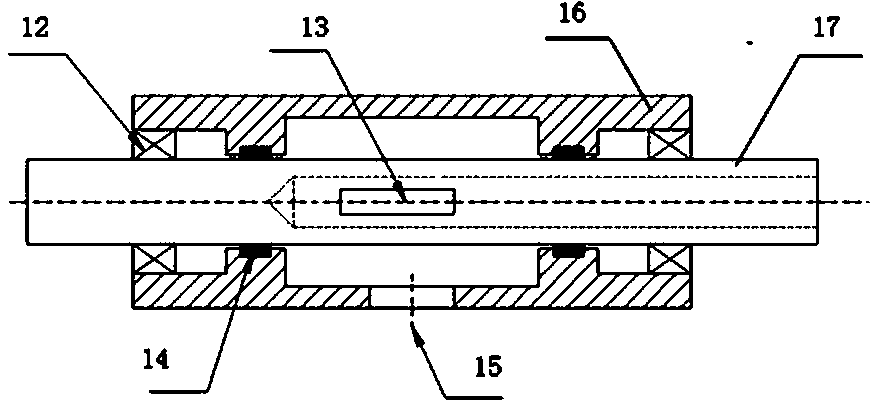

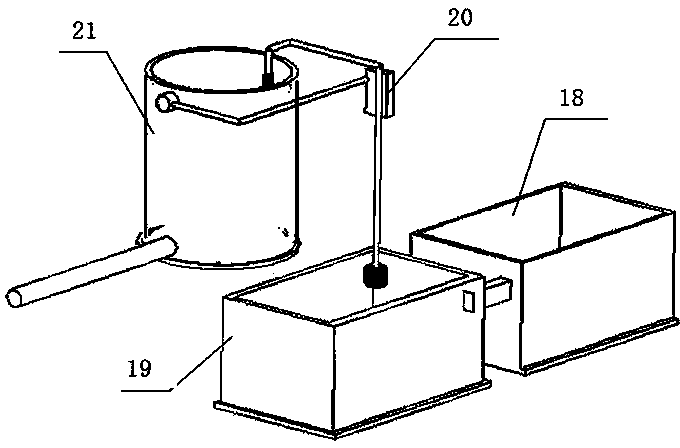

[0018] The present invention includes six parts: a driving mechanism, a water dividing mechanism, a clamping and righting mechanism, a water circulation purification system, a hydraulic station and a cleaning seat; the driving mechanism includes a frequency conversion control cabinet, a driving motor 1 and a reducer 2; the water dividing mechanism includes a centrifugal water pump 9, Electric valve 10, pressure sensor 11, water delivery pipe, transmission shaft shaft head 17, water distribution mechanism housing 16, housing water inlet 15 of water distribution mechanism, transmission shaft shaft head water inlet 13 and bearing 12; the clamping and righting mechanism includes The mobile righting gripper 7, the righting gripper 8 and the support roller 6 arranged on the cleaning seat; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com