High-efficiency energy-saving heating base

A heating base, high-efficiency and energy-saving technology, applied in the direction of heating devices, etc., can solve the problems of energy waste and the inability of the heater to keep warm, and achieve the effect of increasing the heating area, reducing the loss of heat, and increasing the heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

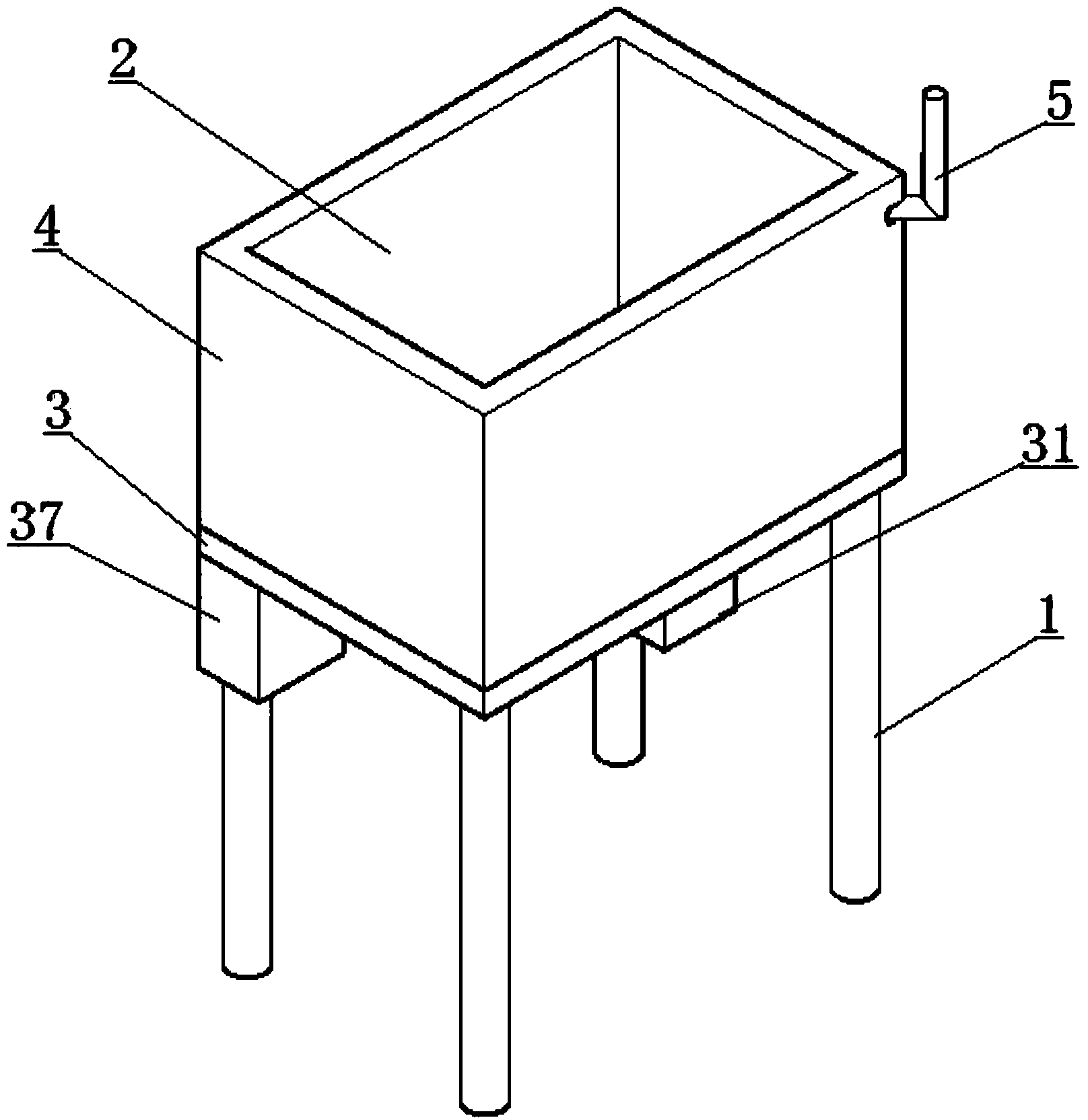

[0026] Such as figure 1 The high-efficiency and energy-saving heating base shown includes a support 1, a heat preservation seat 2 and a smoke exhaust pipe 5. The heat preservation seat 2 is installed on the support 1, and the smoke exhaust pipe 5 is fixed on the heat preservation seat 2. The heat preservation seat 2 includes the bottom of the seat body 3 and side walls 4,

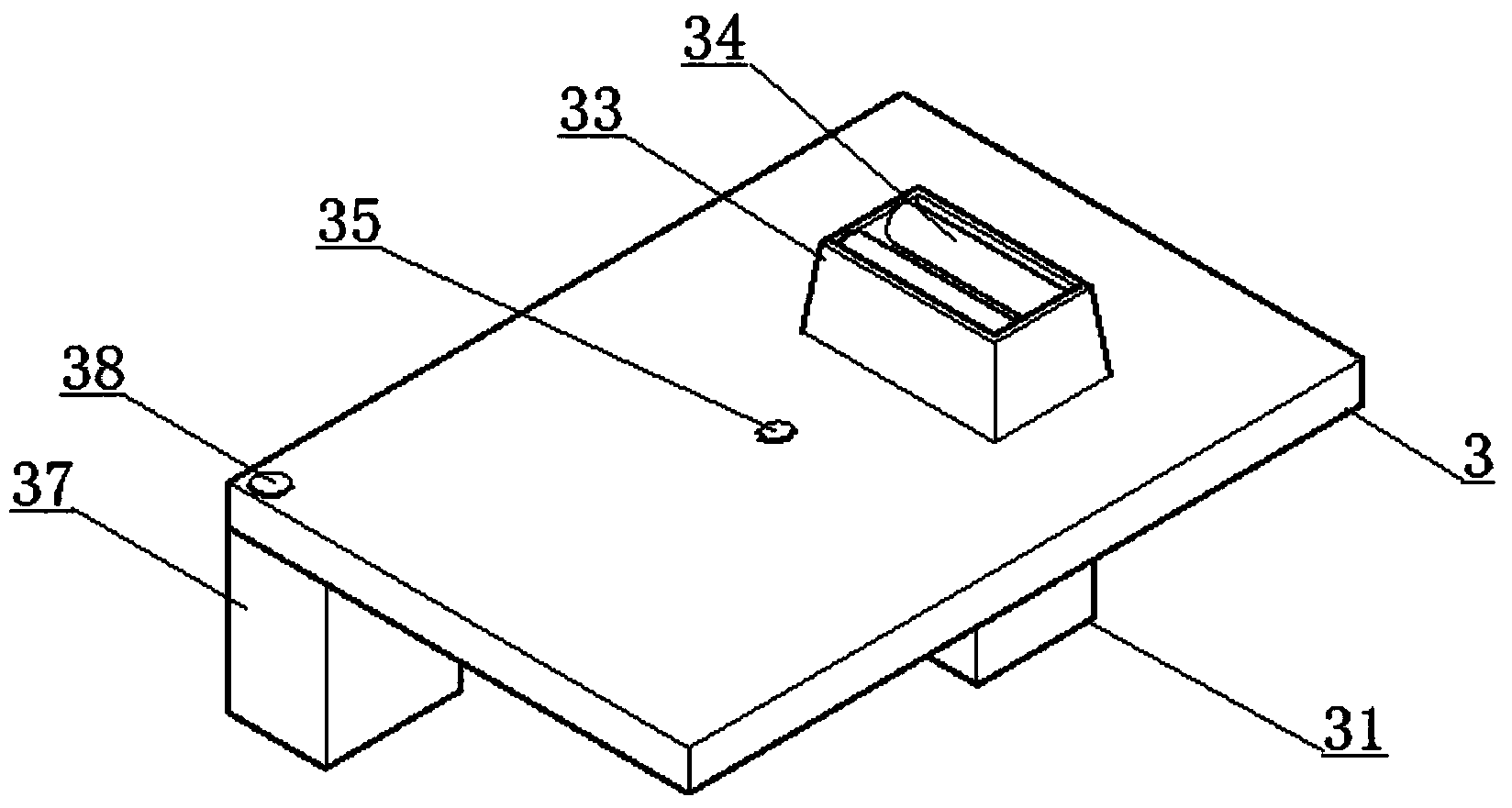

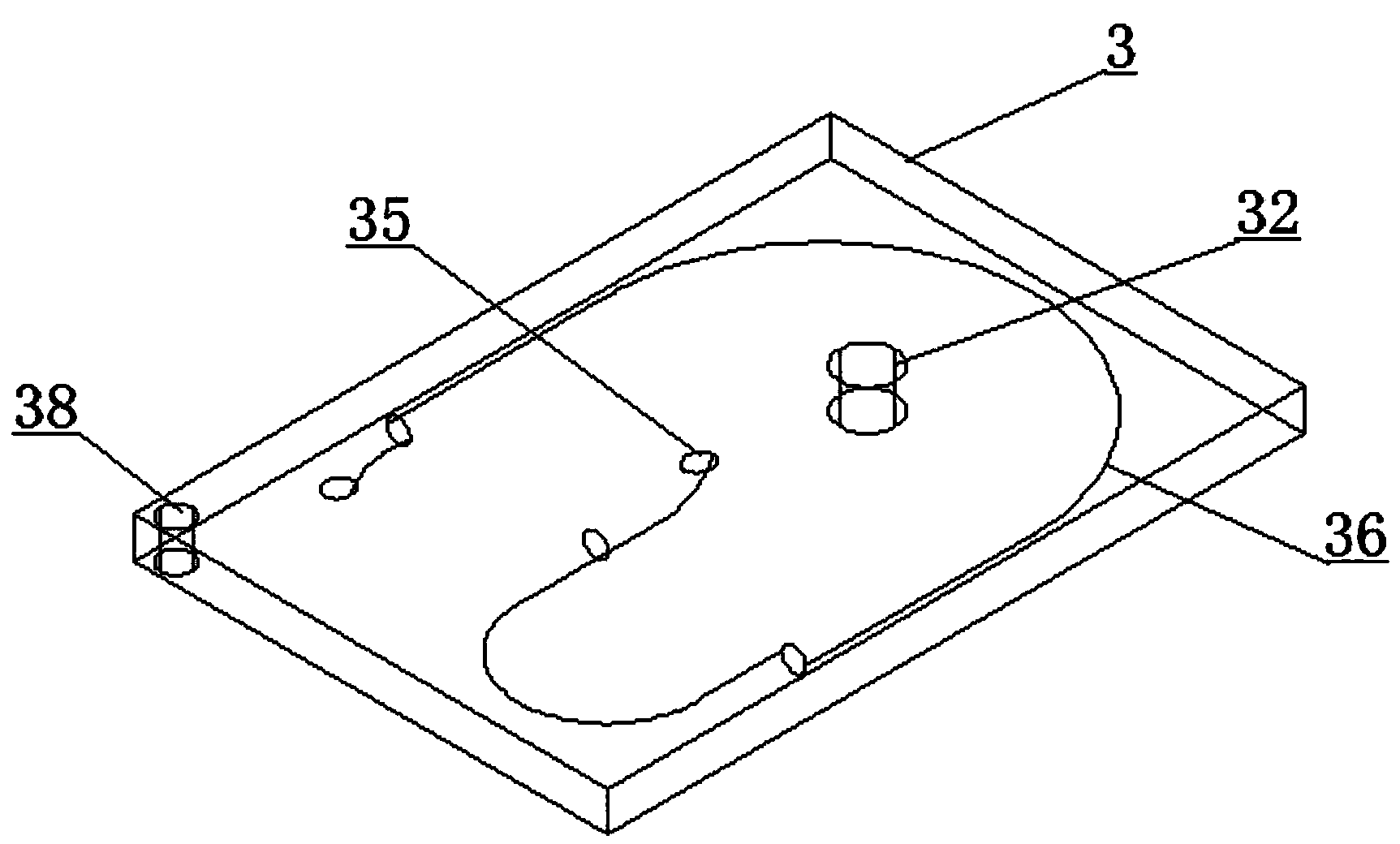

[0027] Such as Figure 2~3 Shown is a schematic diagram of the bottom 3 of the high-efficiency energy-saving heating base heat preservation seat 2. The bottom 3 of the base includes a burner 31, a furnace mouth 32, a heat receiver 33, a smoke inlet 35, a bottom flue 36, a smoking machine 37 and a bottom smoke outlet. Port 38, wherein burner head 31 and heat receiver 33 are respectively connected to the upper and lower sides of base body bottom 3, and the centers of burner head 31 and heat receiver 33 are on the same vertical line as the center of burner mouth 32; smoke inlet 35 is at the base body bottom ...

Embodiment 2

[0031] In order to increase the absorption conversion rate of the side wall 4 to the heat energy of the hot smoke in the side wall flue 41, the connection of the bottom smoke outlet 38 on the side wall 4 and the connection of the smoke exhaust pipe 5 on the side wall 4 are located at On the two opposite corners of the side wall 4, the side wall flues 41 can be 2, 4, 6, etc., which are respectively connected to the smoke exhaust port 38 and the smoke exhaust pipe 5, and the side wall flues 41 are on the side 4 Each side can be straight or curved.

Embodiment 3

[0033] In order to reduce soot remaining in the heat preservation flue, the heat preservation pipe 41 inside the side wall 4 forms an angle of 40° with the horizontal plane. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com