Composite stainless steel pot

A stainless steel pot and stainless steel layer technology, which is applied in the direction of utensils with enlarged heating surfaces, special materials for cooking utensils, etc., can solve the problems of uneven heating, large temperature difference, poor thermal conductivity, etc. , the effect of preventing food from being burnt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

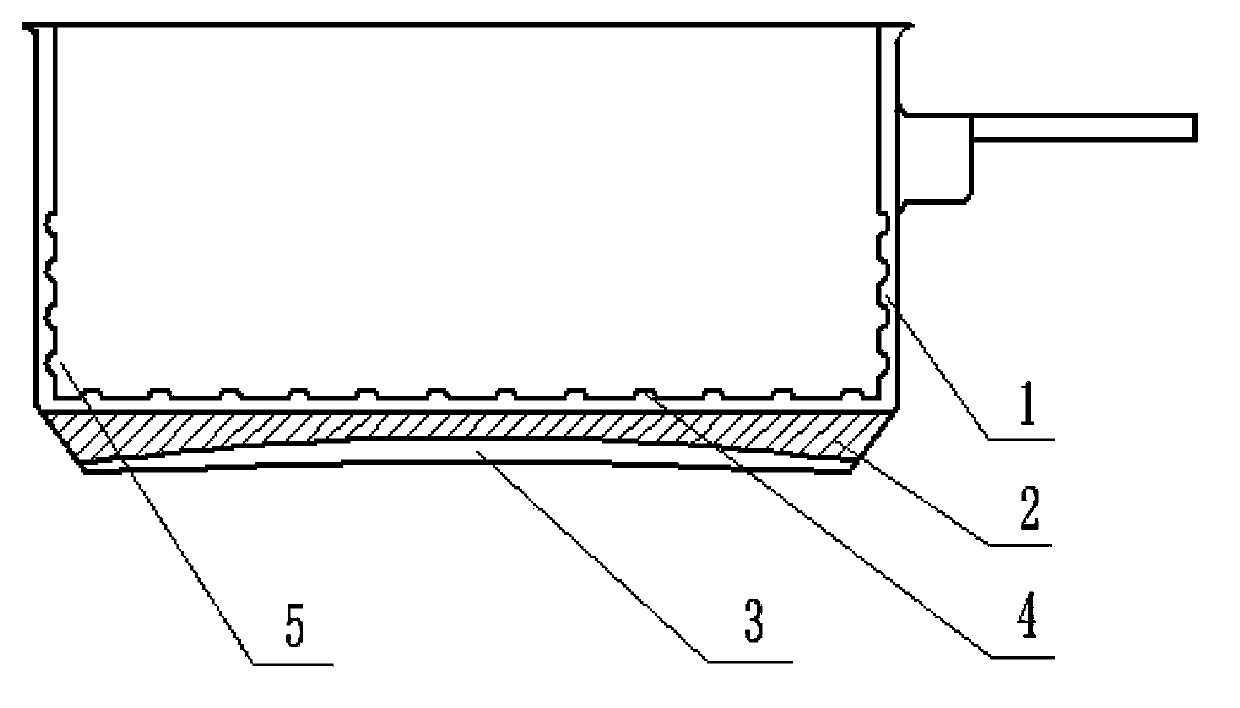

[0011] The invention consists of a stainless steel pot body 1 and a pot bottom. The pot bottom is divided into two layers, one layer is an aluminum-copper alloy layer 2 with better heat conduction and heat distribution performance, and the other is a supporting heating layer stainless steel layer 3 with good mechanical properties. , the two plates are pressed together to form the bottom of the pot. The curved design of the lower stainless steel layer 3 and the aluminum-copper alloy layer 2 increases the heating area of the bottom of the pot. The bottom of the stainless steel pot body 1 is covered with small protrusions 4, and each small protrusion Up to 4 is equivalent to a small heating source, which not only increases the heating area, but also reduces the high-temperature gathering surface between food and the bottom of the stainless steel pot. It h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com