Propeller boss cap comprising fins

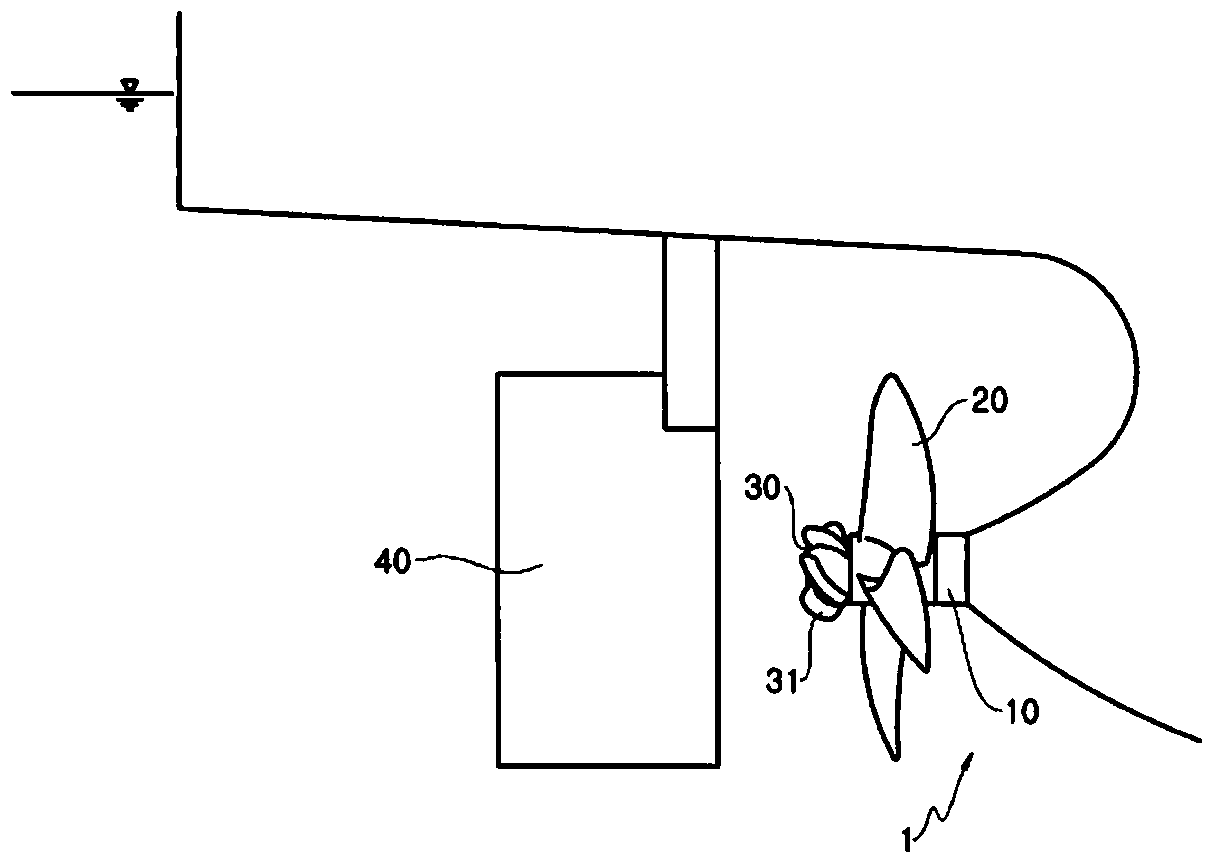

A propeller hub and propeller technology, applied in rotating propellers, rotary propellers, ship propulsion, etc., can solve the problems of reducing pressure difference, hindering propulsion efficiency, not greatly reducing hub vortex cavitation, etc., and achieving improved propulsion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

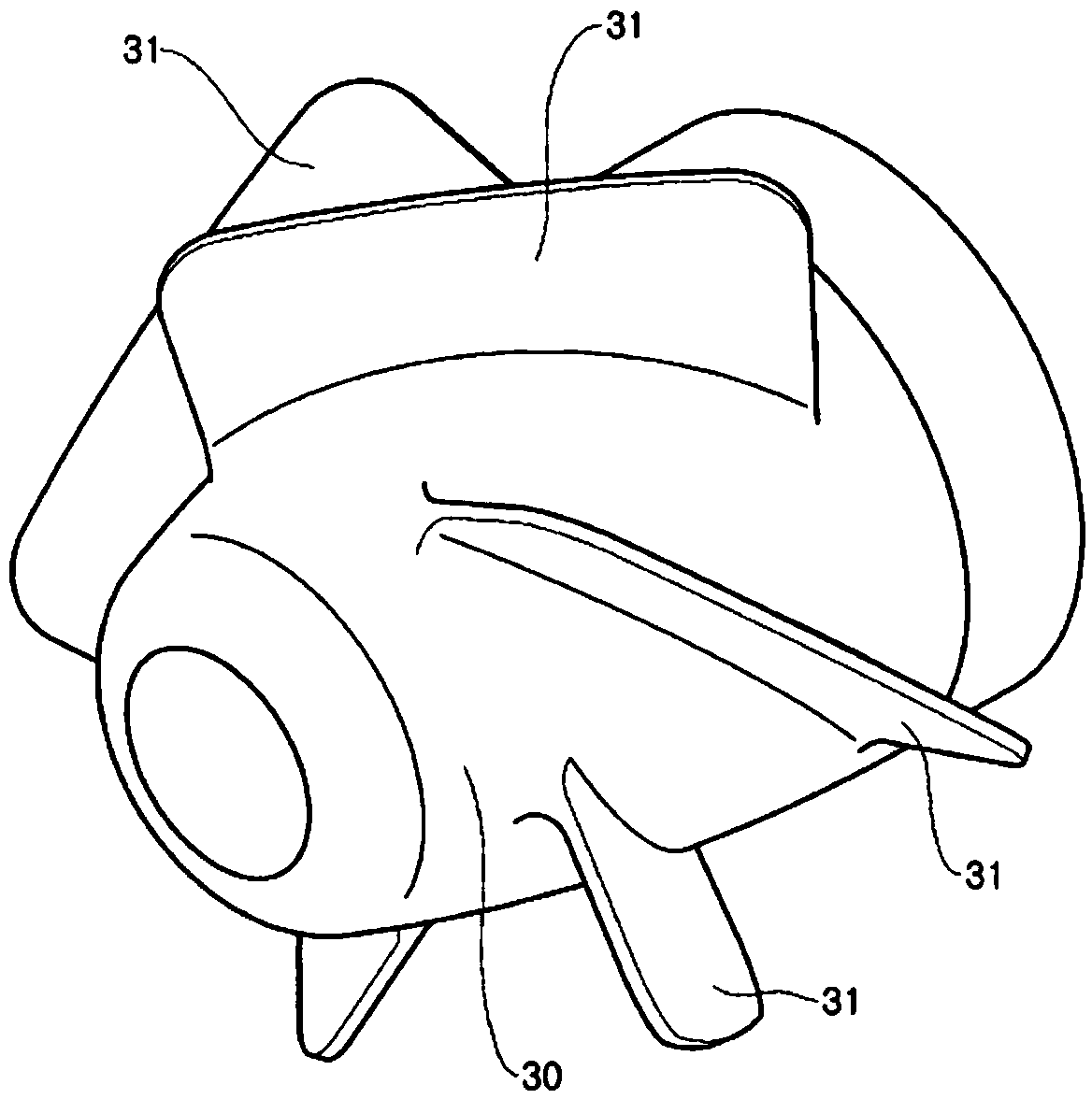

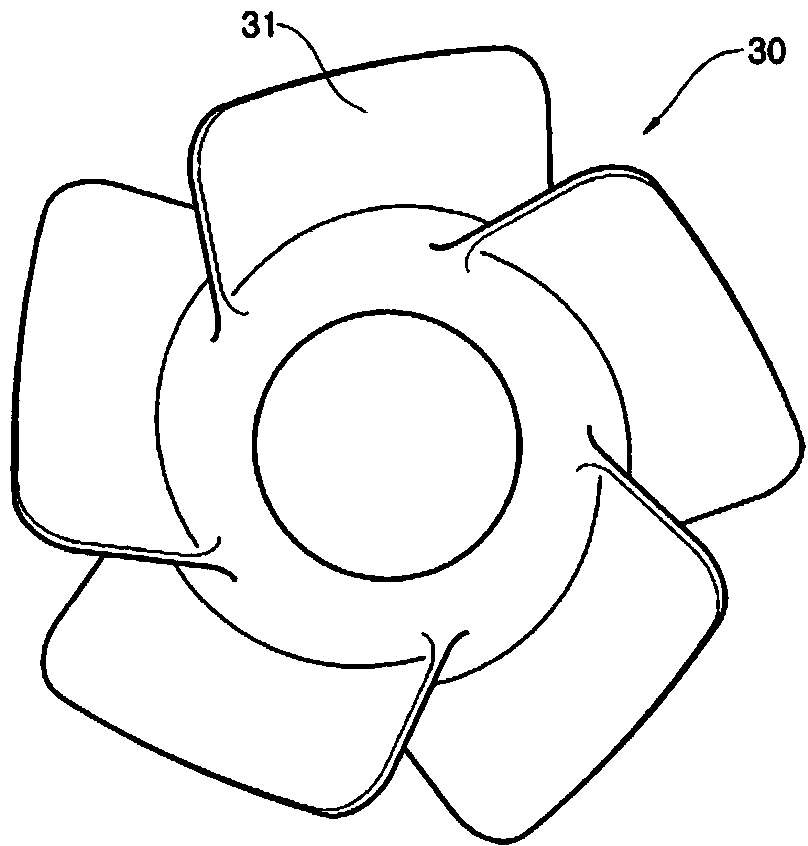

[0044] Figure 5 is a perspective view showing a hub cap according to the present invention. Such as Figure 5 As shown, a hub cap 100 according to the present invention includes a plurality of fins 110 formed along a perimeter, and an end plate 111 formed at the end of each fin 110 .

[0045] Figure 6 for showing Figure 5 A side view of the hub cap 100 of , and depicts the arrangement of the fins 110 formed along the periphery of the hub cap 100 . The fins 110 are disposed along the circumference of the hub cap 100 in a helical form.

[0046] Figure 7 A side view of the fin 110 of the hub cap 100 according to the present invention is shown. The end plate 111 is formed on the end of the fin 110, and the end plate 111 functions to prevent fluid flow, which is between the front (propeller side) surface and the rear (rudder side) surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com