Electric power converter

A technology of power converters and capacitors, which is applied in the direction of output power conversion devices, electrical components, circuit devices, etc., and can solve problems such as voltage shocks and shortened extension lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

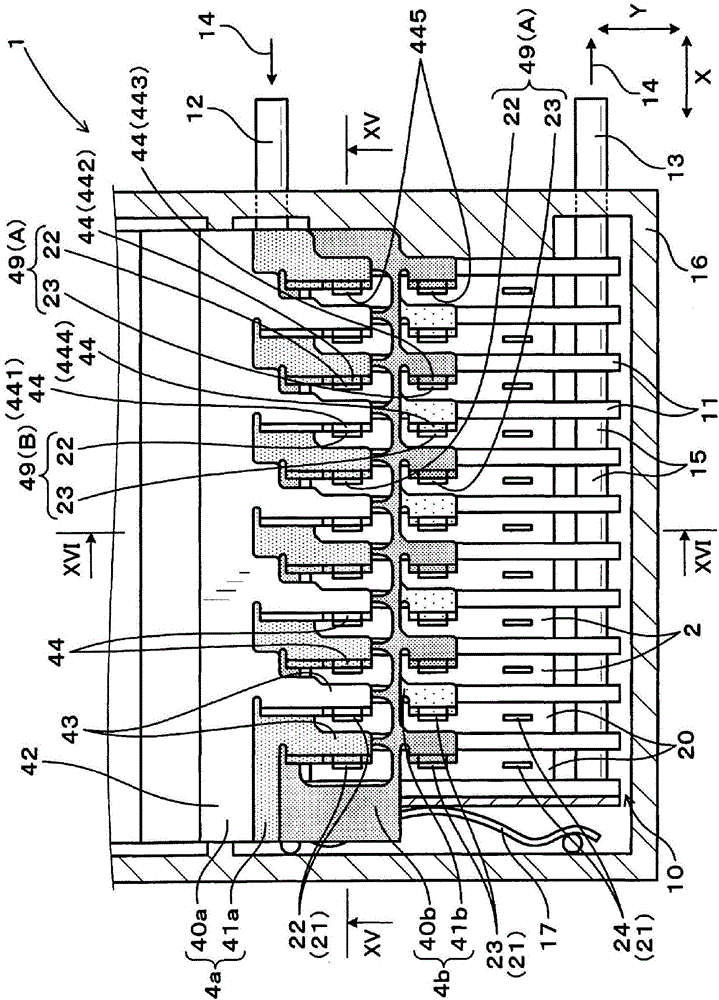

[0179] This embodiment is an example in which the shape of the bus bar 4 and the connection state of the terminal pair 49 are changed.

[0180] Such as Figure 18 As shown, in this embodiment, the terminal pair 49 will adopt any one of the third connection state C or the fourth connection state D.

[0181] In the third connection state C, the positive terminal 22 is connected to the terminal connection portion 441 of the distal plate member 40a of the positive bus bar 4a, and the negative terminal 23 is connected to the terminal connection portion 443 of the distal plate member 40b of the negative bus bar 4b.

[0182] In addition, in the fourth connection state D, the positive terminal 22 is connected to the terminal connection portion 442 of the proximal plate member 41a of the positive bus bar 4a, and the negative terminal 23 is connected to the terminal connection portion 444 of the proximal plate member 41b of the negative bus bar 4b .

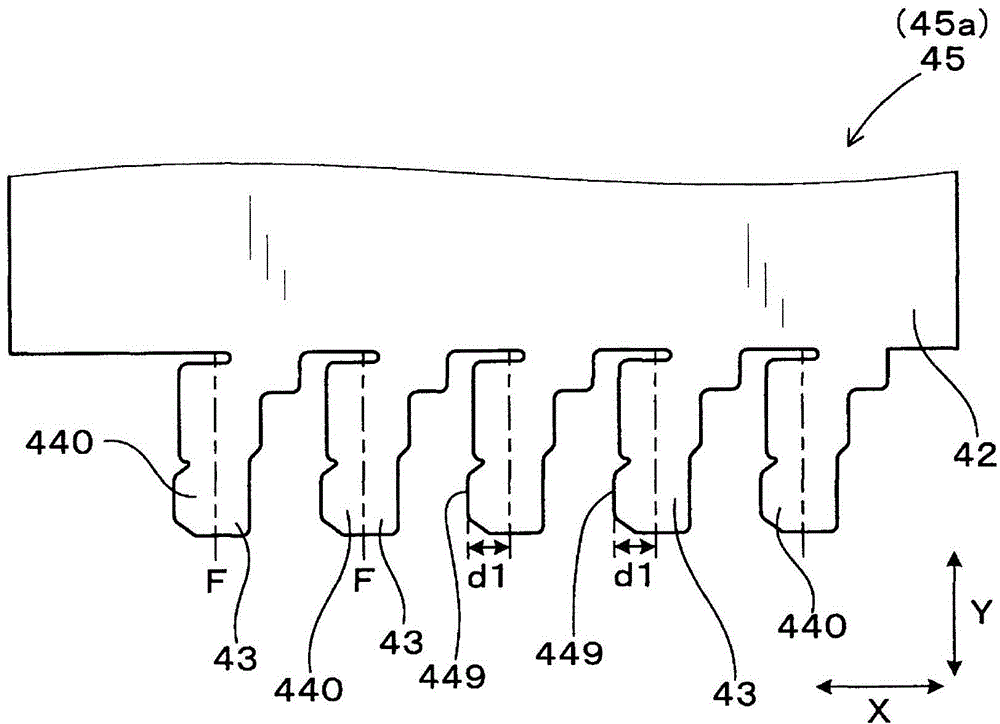

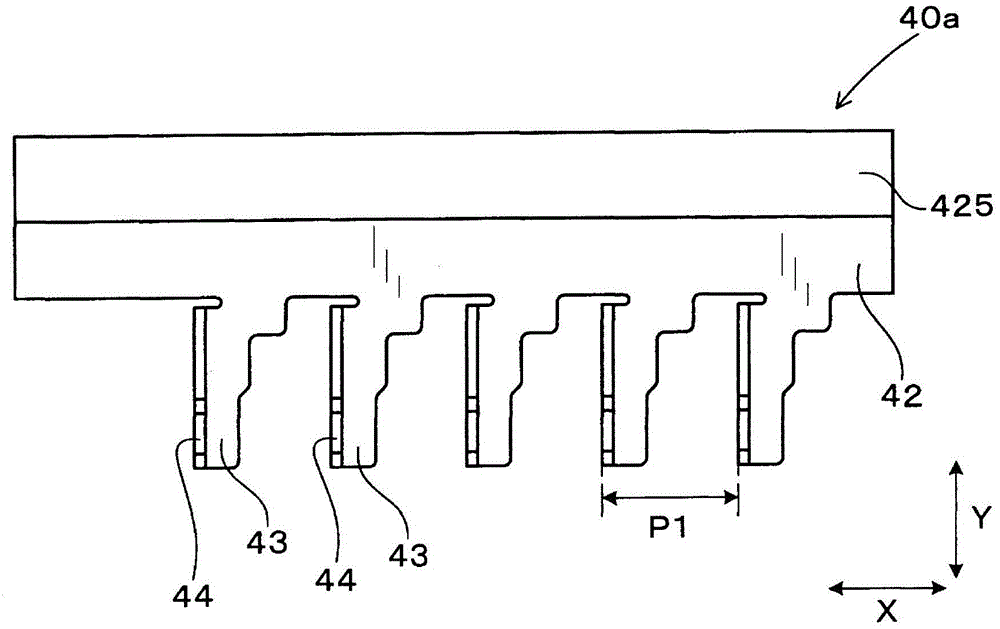

[0183] Such as Figure 19 As sho...

no. 3 approach

[0191] This embodiment is an example in which the configuration of the capacitor 3 is changed.

[0192] Such as Figure 20 and Figure 21 As shown, the capacitor 3 of the present embodiment has a plurality of capacitor elements 30 ( 30 a , 30 b ) connected in parallel to each other.

[0193] Then, each of the plate members 40, 41 constituting the bus bar 4 is connected to a different capacitor element 30a, 30b, respectively.

[0194] The capacitor element 30 includes a proximal capacitor element 30b disposed at a position closer to the sealing portion 20 in the Z direction and a distal capacitor element 30a disposed at a distance from the sealing portion 20 in the Z direction than the distal capacitor element 30a. The proximal capacitor element 30b is further away.

[0195] The distal plate member 40a of the positive bus bar 4a is connected to the positive electrode 33 of the distal capacitor element 30a, and the proximal plate member 41a is connected to the positive electr...

no. 4 approach

[0212] This embodiment is an example in which the positions of the electrodes of the capacitor elements 30a and 30b are changed.

[0213] In this embodiment, if Figure 22 and Figure 23 As shown, the end surface of the proximal capacitor element 30b closer to the control circuit board 19 in the Z direction and the end surface of the distal capacitor element 30a farther from the control circuit board 19 in the Z direction are configured as positive electrodes 33 .

[0214] Furthermore, the end surface of the proximal capacitor element 30b remote from the control circuit board 19 in the Z direction and the end surface of the distal capacitor element 30a close to the control circuit board 19 in the Z direction are configured as negative electrodes 34 .

[0215] The distal plate member 40a of the positive bus bar 4a is connected to the positive electrode 33 of the distal capacitor element 30a.

[0216] Furthermore, the proximal plate member 41a of the positive bus bar 4a is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com