Novel winding method and novel winding machine

A winding method and winding technology, which are used in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve problems such as inability to meet the winding requirements and user inconvenience, achieve simple structure, improve efficiency, and achieve and Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below according to accompanying drawing:

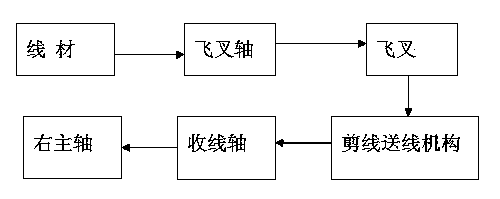

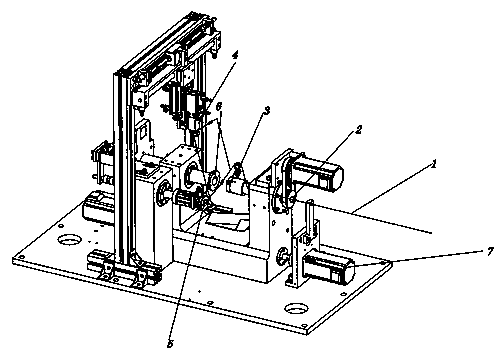

[0013] Such as figure 1 A new winding method is shown, the wire 1 passes through the center of the axis of the fly fork 3, and the thread end is sent to the take-up shaft 5 by the wire cutting and feeding device 4 through the fly fork 3, and then the take-up shaft 5 winds the wire in this direction The required wire 1 is stored to a sufficient length; the right spindle 6 is driven by the spindle motor 7 to wind synchronously, and the take-up shaft 5 is fed synchronously, and the other direction is wound by the flying fork shaft 2 in the same direction as the right spindle at twice the speed of the right spindle , until a coil is wound.

[0014] The so-called "α" winding process is characterized by first sending the end of the thread to one end by a mechanical device, and then storing the length of the wire required for winding in one direction of the coil by the take-up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com