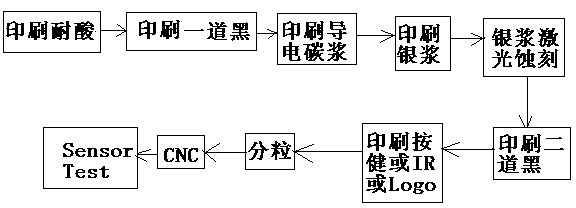

Manufacturing process for functional sheet of OGS (One Glass Solution) touch screen

A manufacturing process and touch screen technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc., can solve the problems of high cost of projected capacitive touch modules and low GG bonding yield, etc. The effect of low cost, simple production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The invention is an OGS touch screen with a low-cost printing process. The OGS touch screen with a low-cost printing process includes the strengthening and printing of the structural component CG of the touch screen, and the coating and graphic production of the functional component sensor. The present invention abandons the sensor bonding of the traditional double-layer structure (CG+sensor) of the capacitive touch screen, reduces the link that has the greatest impact on the yield rate of the touch screen, and reduces costs. The present invention is different from the Huangguang OGS capacitive screen. The present invention is clearly positioned on the automatic capacitive solution of single-point and 2-point touch, and focuses on the field of low-end capacitive screens. Compared with the traditional yellow light OGS capacitive touch screen, the present invention reduces the number of processes. The normal yellow light single-sided multi-point metal bridging OGS needs to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com