Fuel gas watchcase leakage detection device and detection method

A detection device and gas meter technology, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of low efficiency during detection, damage and deformation, and affect the detection of gas leakage performance of products Results and other issues, to achieve the effect of improving detection efficiency and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with each specific embodiment and accompanying drawing, the present invention will be further described:

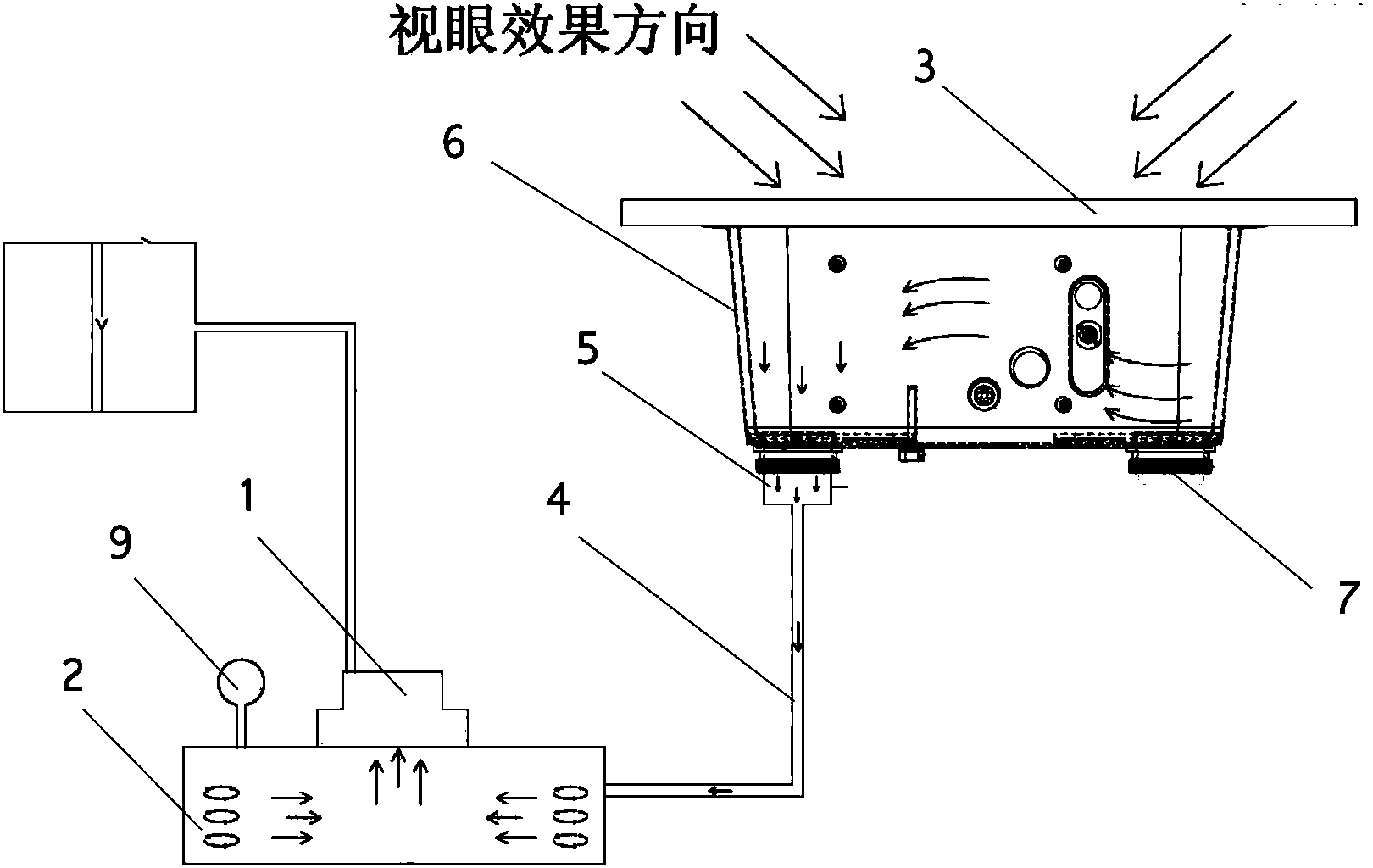

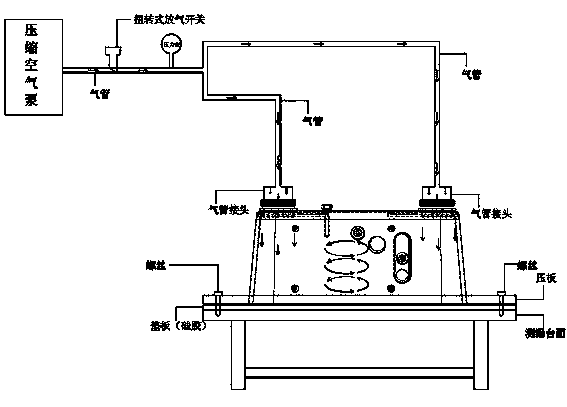

[0019] See figure 2 , the gas watch case air leakage detection device disclosed by the present invention, it comprises a vacuum pump 1, a pump case 2, a transparent watch case sealing plate 3, wherein the vacuum pump 1 is installed on the pump case 2, and communicates with the pump case 2 , the pump box 2 is airtightly connected with the external tooth head of the watch case 6 through the air pipe 4 and the air pipe joint 5, and rubber plugs 7 are installed on other corresponding open parts of the watch case 6, so that the gas is inhaled at the open part, and at the upper end of the watch case 6 The opening is laid with sealing ring, and the watch case sealing plate 3 is added above the sealing ring.

[0020] The pump box 2 is provided with a barometer 9 . To measure the degree of vacuum in the case 6 to determine whether it meets the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com