LED lamp for inspection and maintenance

A technology for inspection and maintenance of LED lamps, which is applied to components of lighting devices, damage prevention measures for lighting devices, semiconductor devices of light-emitting elements, etc., can solve problems such as inability to obtain bright light and small limitations, and achieve good stability Low cost and damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

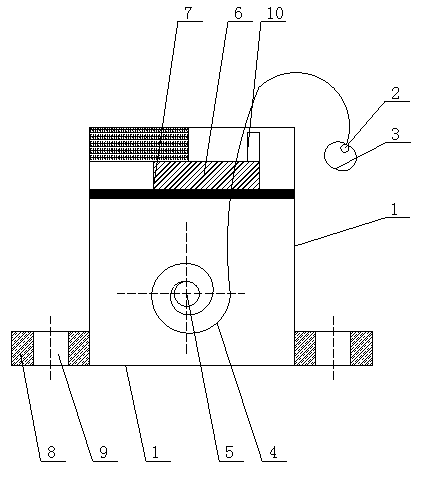

[0015] Such as figure 1 As shown, an LED lamp for inspection and maintenance of the present invention includes a lamp body 1, an LED lamp 2 is movably arranged in the lamp body 1, and an LED lamp protective cover 3 is arranged on the periphery of the LED lamp 2. The LED lamp 2 is fixed on one end of the connecting tape 4, the other end of the connecting tape 4 is fixed on the movable shaft 5, the movable shaft 5 is fixed inside the lamp body 1, and the lamp body 1 has a sliding door on the top of the lamp body 1 6. The lamp body sliding door 6 is movably fixed to the inside of the lamp body 1 through a guide rail 7. A lamp body fixing plate 8 is provided on both sides of the lamp body 1, and a screw hole 9 is provided on the lamp body fixing plate 8. The lamp body 1 is fixed by a screw hole 9, the lamp body sliding door 6 is provided with a handle 10, and the LED lamp protective cover 3 is a spherical translucent plastic cover, which is small in size, energy-saving and envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com