A valve core group switching control mechanism

A control mechanism and spool technology, applied to valve details, multi-way valves, valve devices, etc., can solve problems such as inconvenient use and troublesome operation, and achieve the effect of short operation stroke, small operation force and novel control mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

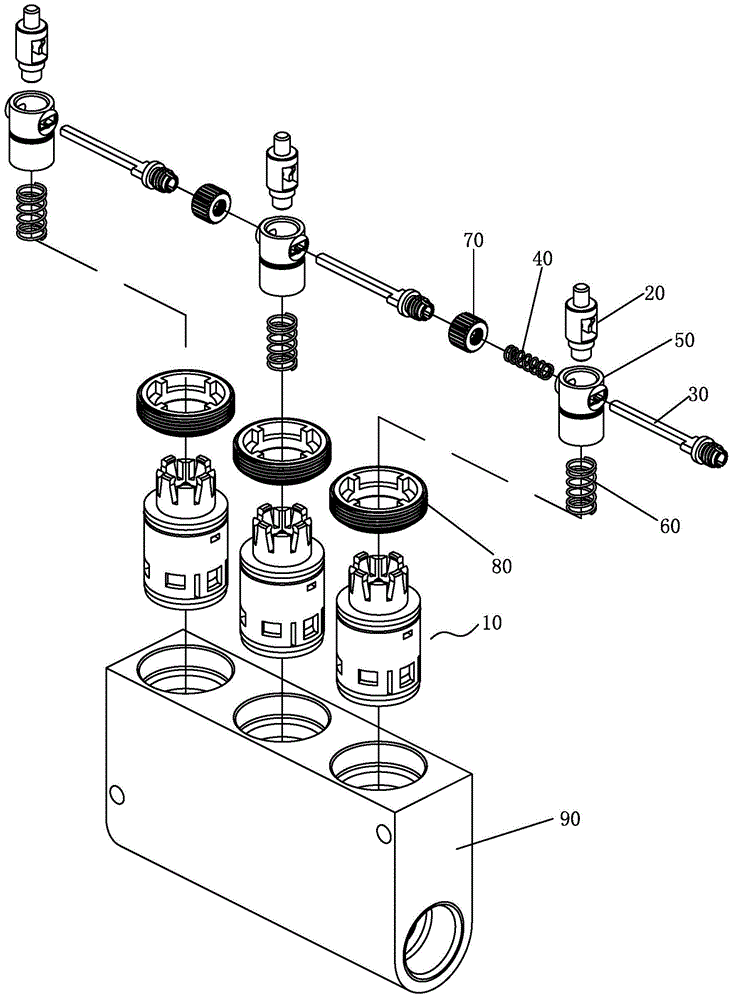

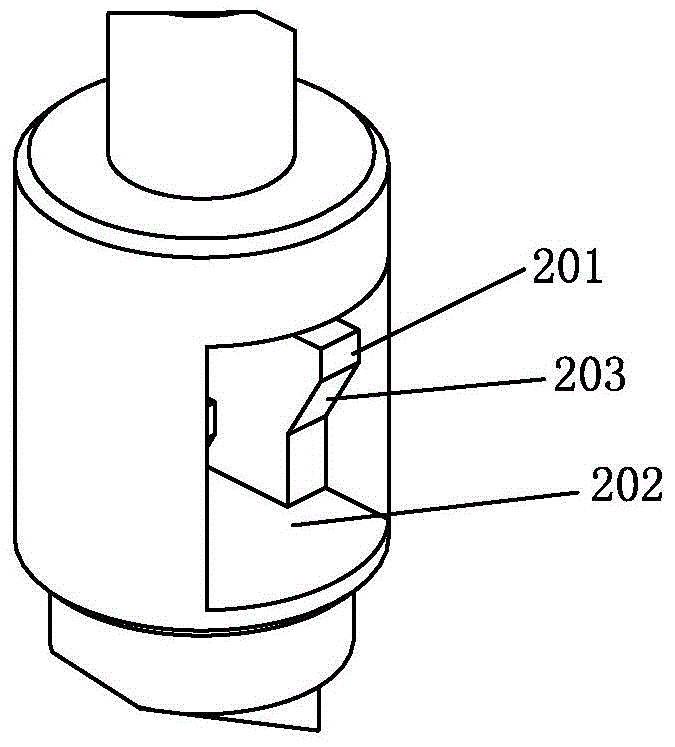

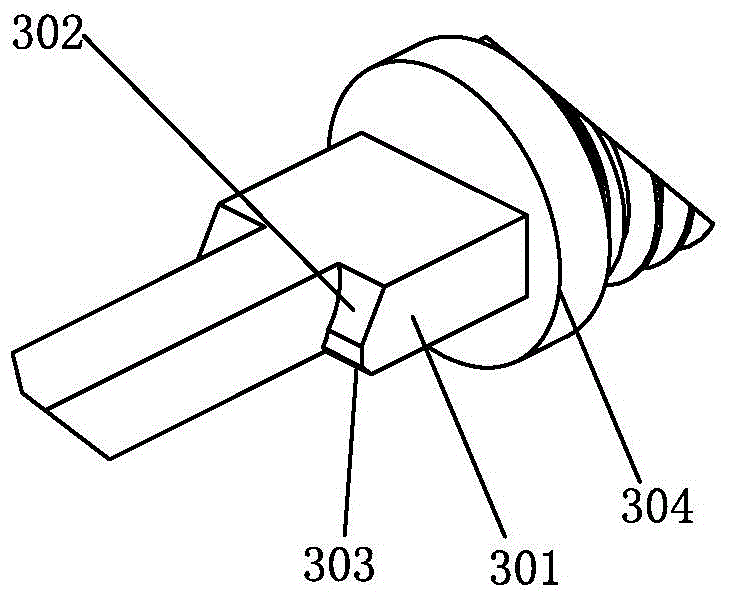

[0030] For the embodiment, please refer to the accompanying drawings, a spool group switching control mechanism of the present invention includes three spools 10 (the spools 10 are push-type spools), and also includes three button modules and a first The elastic member 40, each button module includes a button 20 and a control rod 30 for opening the spool 10, the button 20 is matched with the spool 10, the control rod 30 can move along its axial direction and is assembled on the button 20, and the control rod A locking structure for locking the key 20 is fitted between the key 30 and the key 20 . The control rods of the three button modules are coaxially linked, and one of the control rods is connected with a first elastic member 40 for returning (of course, the three control rods can also be connected to a first elastic member 40 respectively). Among the three buttons 20, two buttons are in the state of returning, and one button is in the state of being pressed. Any button in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com