Penetrated screw nut

A nut and ring technology, applied in the field of penetrating nut, can solve the problems of inflow and riveting strength, etc., and achieve the effect of preventing strength reduction and excellent anti-rotation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, preferred embodiments of the present invention will be described.

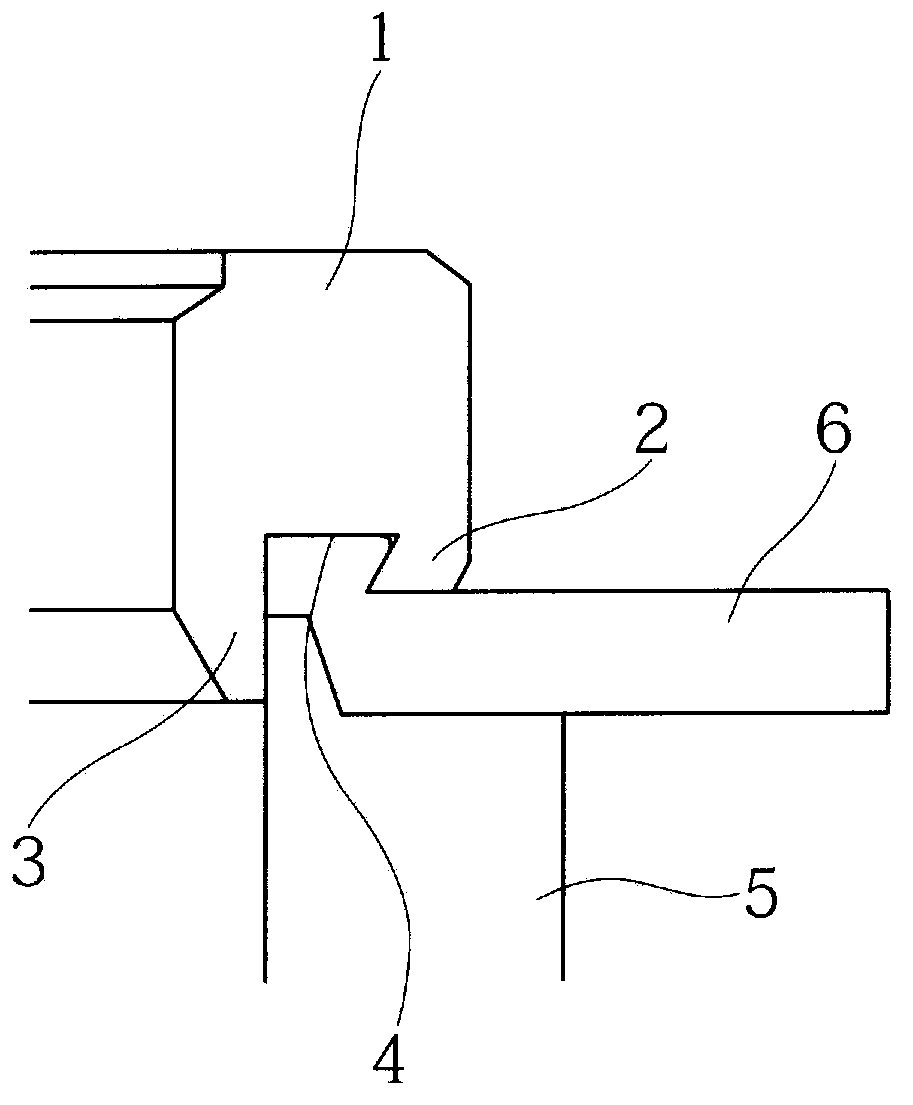

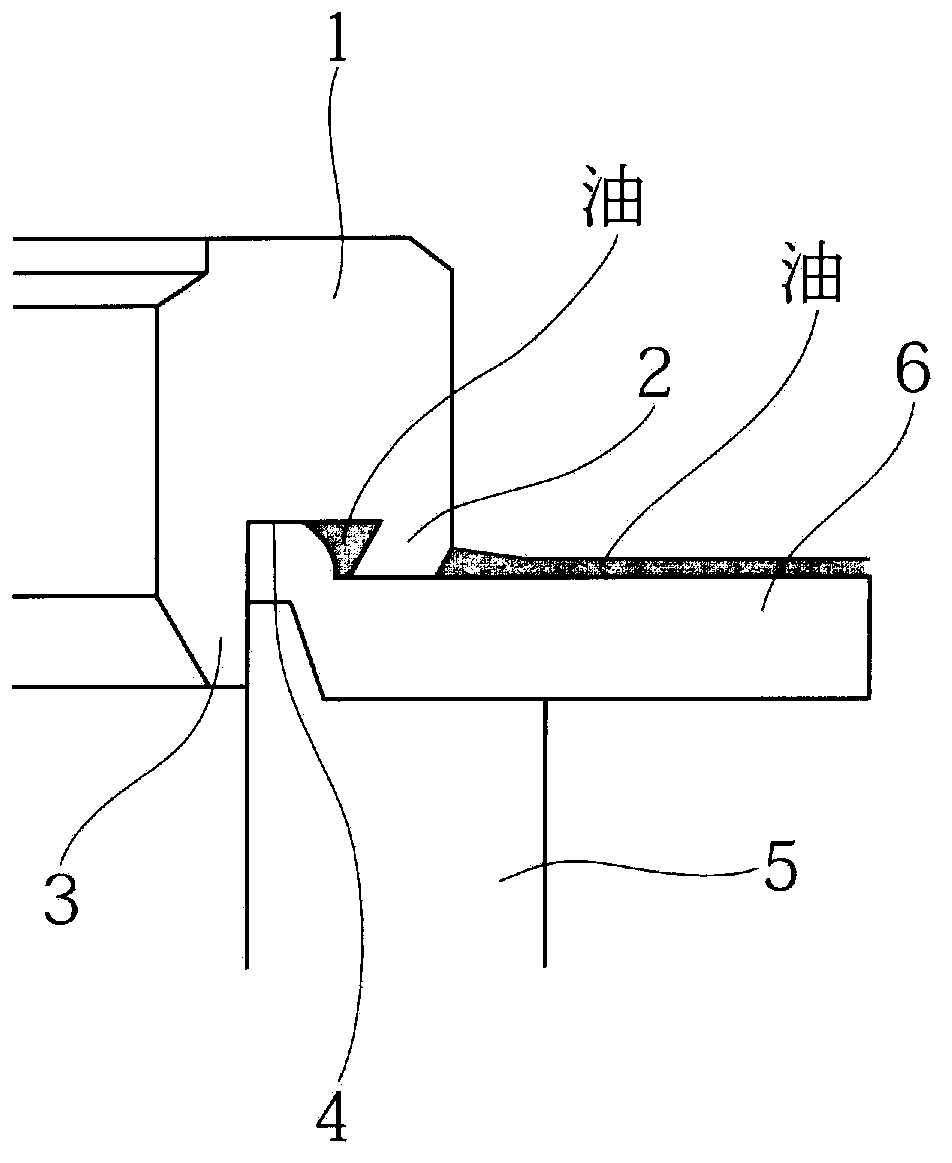

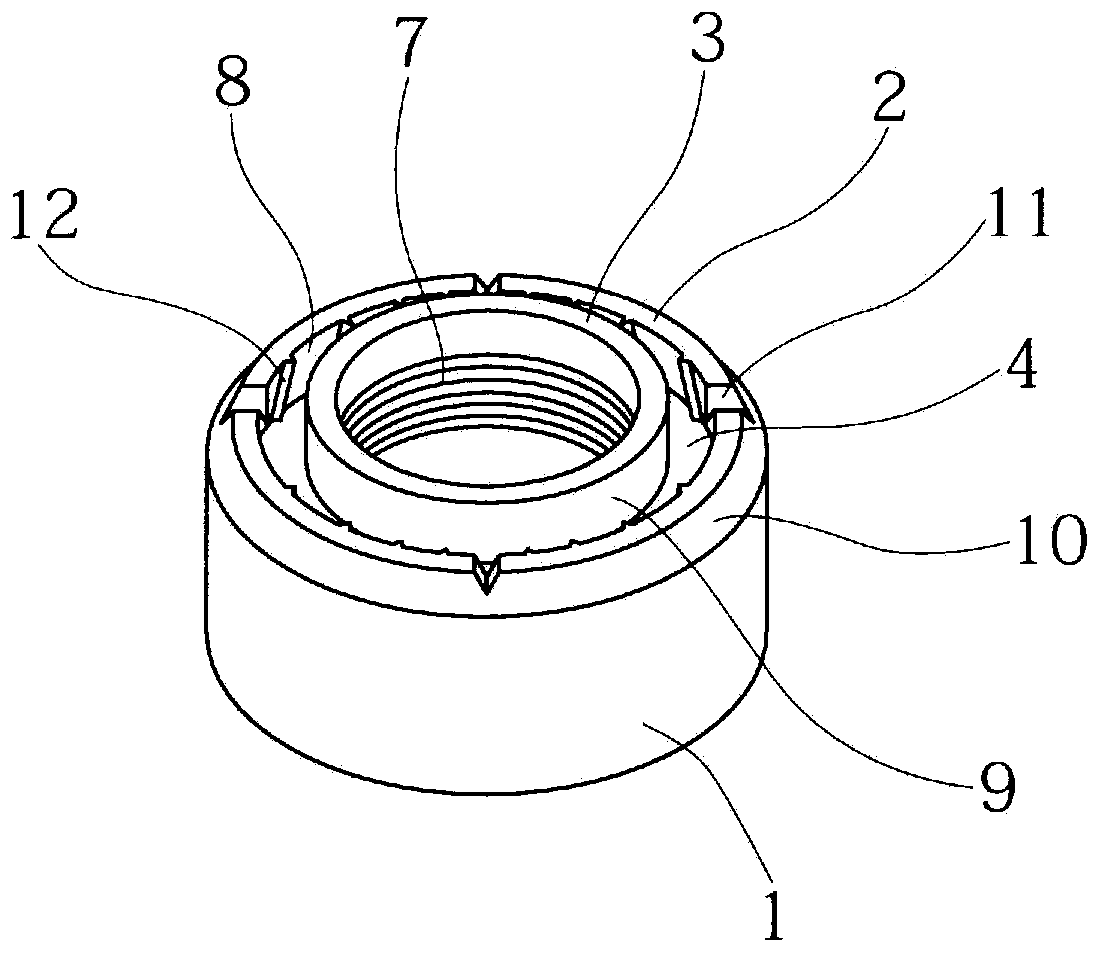

[0037] image 3 , Figure 4 It is a perspective view which shows 1st Embodiment of this invention. The penetrating nut of the present invention is also the same as the conventional penetrating nut, and has: an outer peripheral annular protrusion 2 protruding from the outer periphery of the lower surface of the nut main body 1; an inner periphery protruding from the center of the lower surface of the nut main body 1 An annular protrusion 3 ; and a riveting groove 4 formed between the outer peripheral annular protrusion 2 and the inner peripheral annular protrusion 3 . The inner annular protrusion 3 protrudes downward more than the outer annular protrusion 2 . In addition, the internal thread 7 is formed on the inner surface of the inner peripheral annular protrusion 3, which is used to fasten other components with bolts, which is self-evident.

[0038] The inner peripheral surface 8 of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com