Damping blade with piezoelectric material vibration reduction structure

A technology of piezoelectric material and vibration damping structure, applied in the direction of blade support element, engine element, machine/engine, etc., can solve the problems of increasing the damping contact surface area, increasing the centrifugal force of the blade, changing the flow part, etc., to increase the number of blades The effect of dry friction damping, increasing the contact dry friction area, and adjusting the resonant frequency of the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

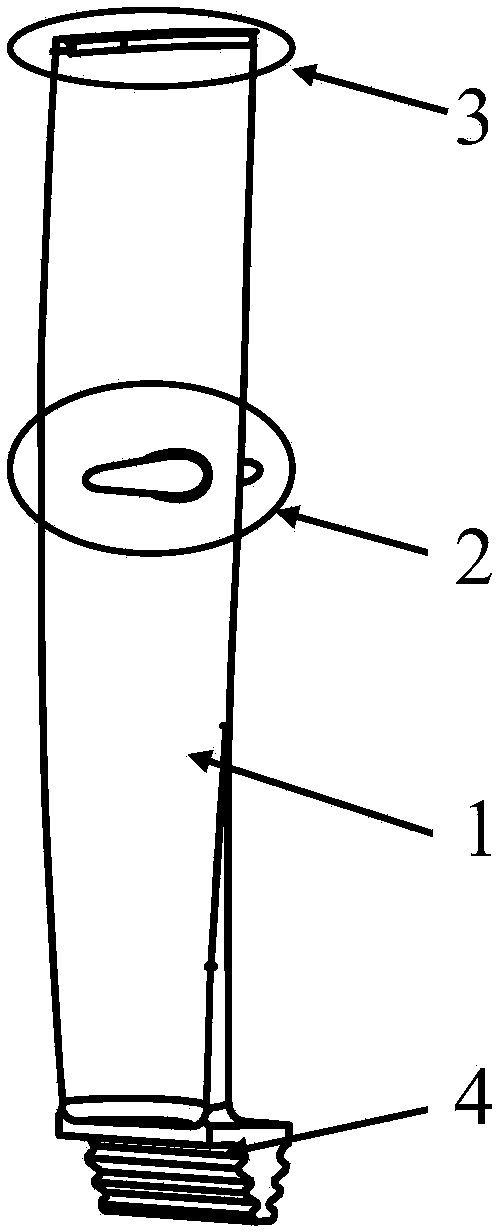

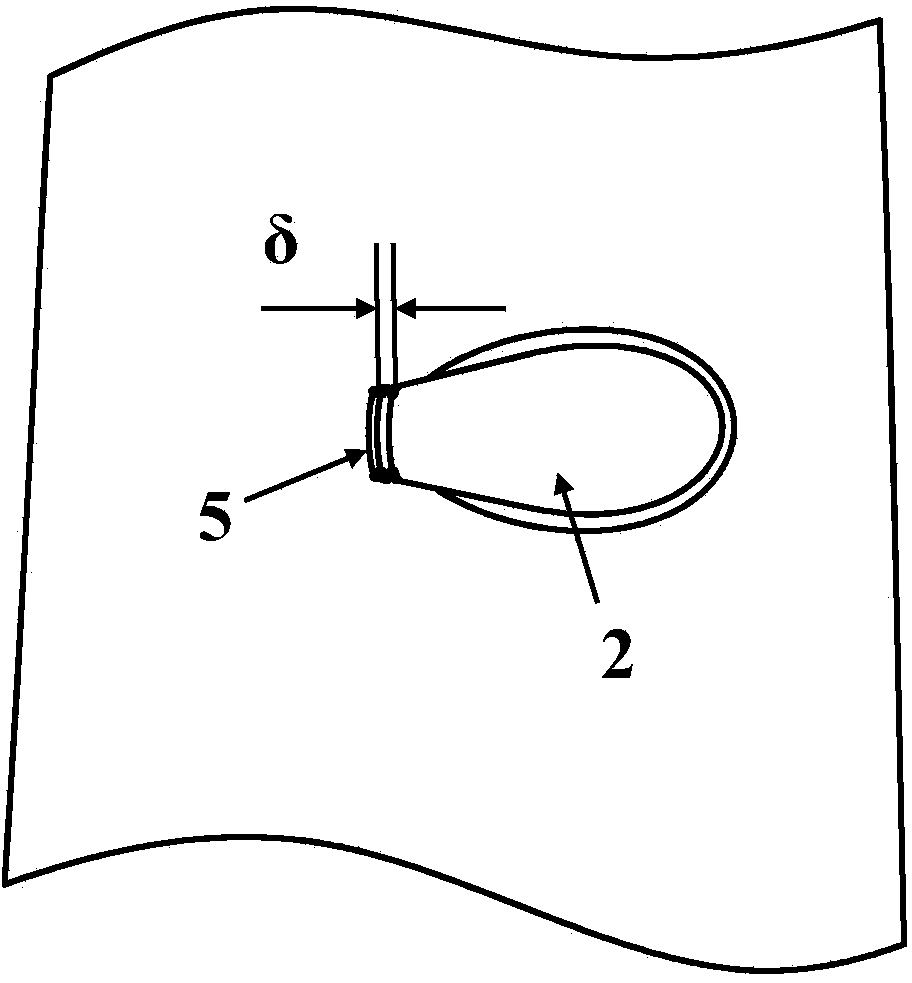

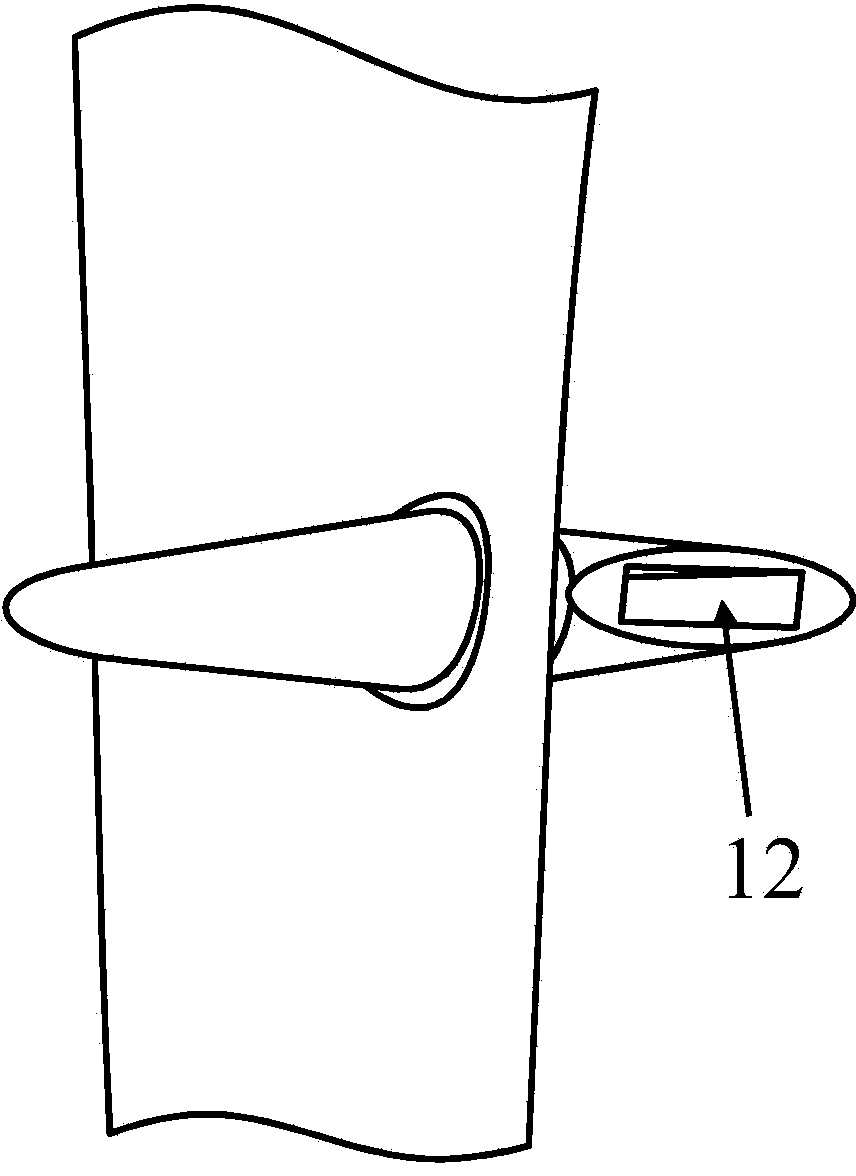

[0027] see Figure 1 to Figure 3 , the damping blade with a piezoelectric material damping structure of the present invention includes: a blade body 1, a blade root 4 and a boss pull 2 arranged on the blade body 1, and the boss pull 2 is provided with a boss pull through Holes 12, a boss pull gold pressure surface contact block 5 is provided on the boss pull gold through hole 12 on the damping blade pressure side side, and a boss pull gold through hole 12 is provided on the damp blade suction side side. The platform pull gold suction surface contact block 6 is provided with an insulating slide block 7 in the boss pull gold through hole 12 between the boss pull gold pressure surface contact block 5 and the boss pull gold suction surface contact block 6. The block 7 has a hollow cavity, and the contact block 5 on the pressure surface of the raised gold pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com