Quenching device

A technology of quenching device and quenching box, which is applied in the direction of quenching device, heat treatment equipment, manufacturing tools, etc., and can solve the problems such as water is easy to disperse, water in the quenching box splashes outside the box, and workpieces cannot be quenched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

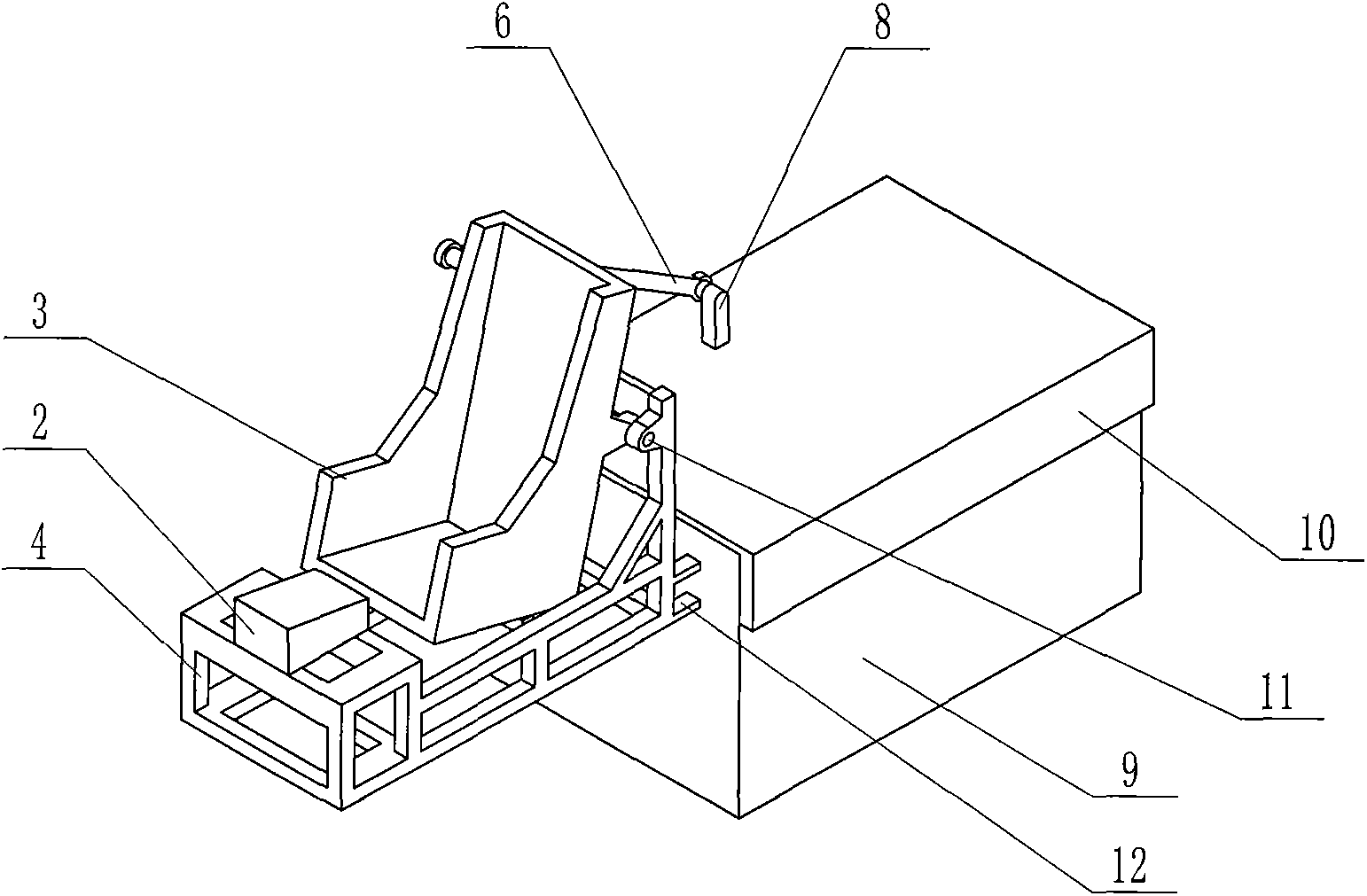

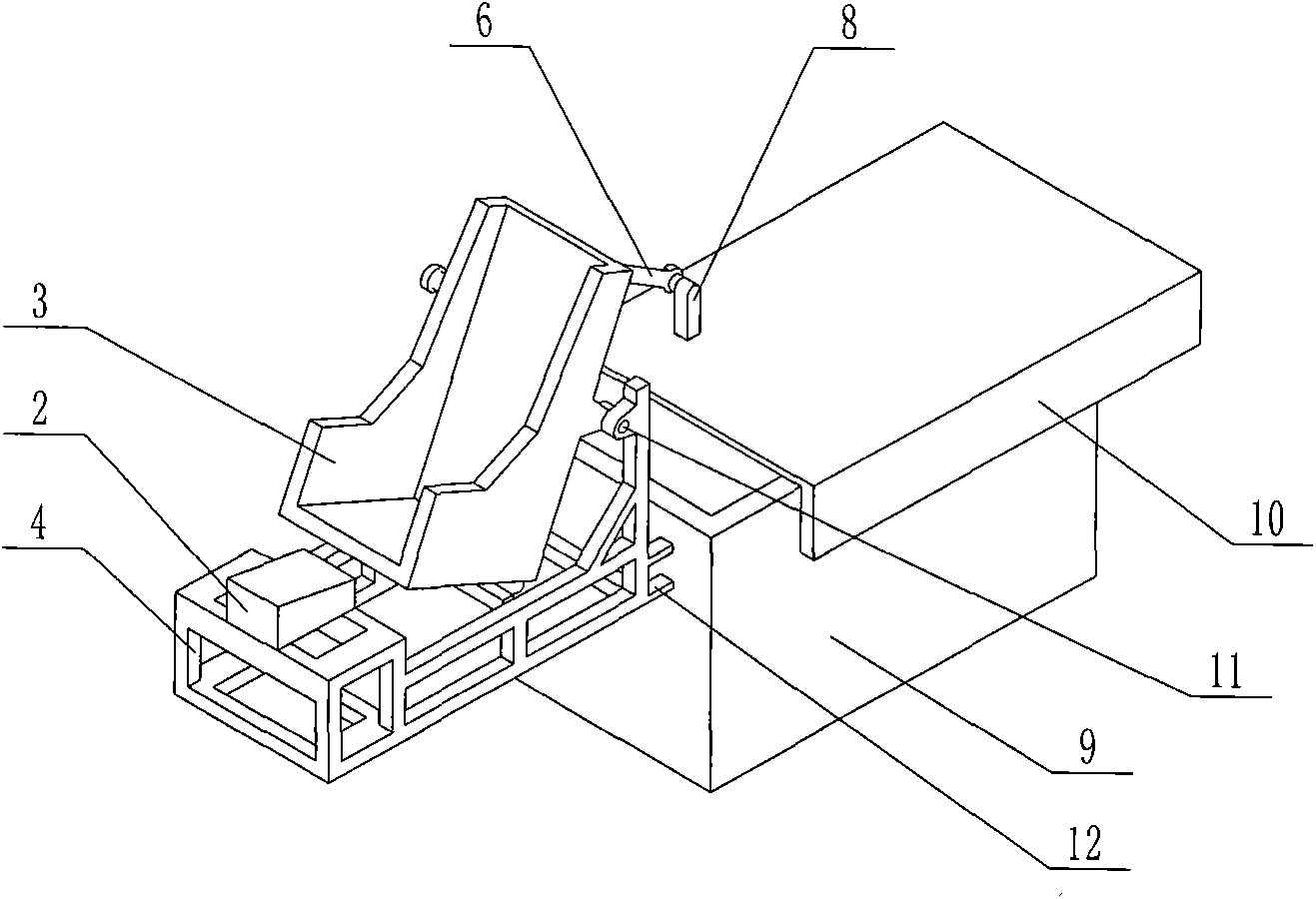

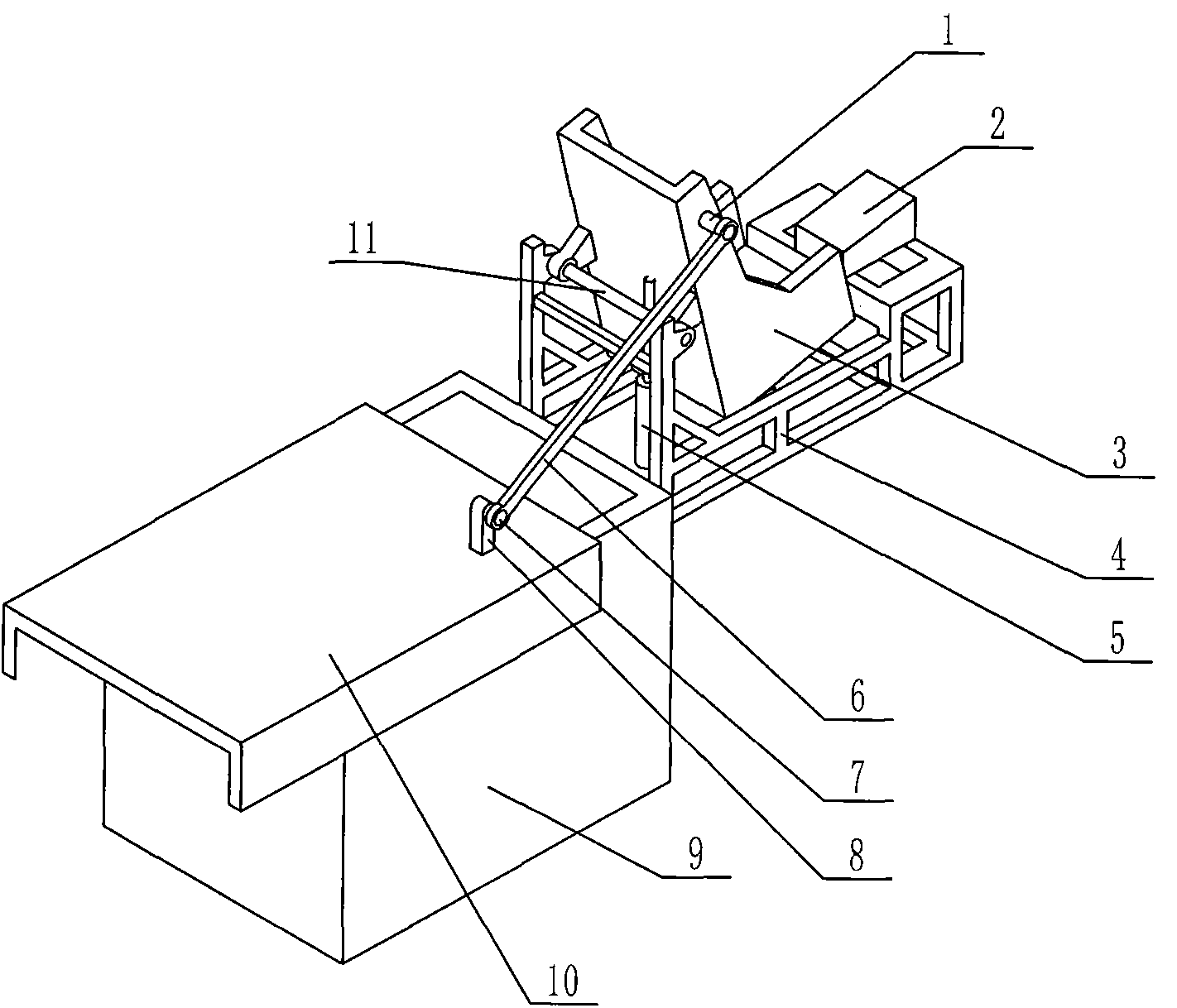

[0013] like Figure 1 to Figure 3 The quenching device shown, Figure 4 guide rod shown and Figure 5 It can be seen from the shown slide cover that the quenching device includes a slide table 2, a loading hopper 3, a support 4, a hydraulic cylinder 5, a long pin shaft 11, and a quenching box 9; the slide table 2 is fixedly arranged on the support 4. At the bottom of the bracket 4 and between the quenching box 9, a rod 12 welded on the quenching box 9 is arranged, and then the bracket 4 is fixed on one side of the quenching box 9. The loading hopper 3 is located above and in the middle of the bracket 4, and is movably connected to the bracket 4 through a long pin shaft 11. A hydraulic cylinder 5 is arranged below the loading hopper 3, and the hydraulic cylinder 5 can drive the loading hopper 3 around through its telescopic movement. The long pin shaft 11 is turned ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com