High-speed feeding and continuous sorting method and device of regular objects

A sorting device and object technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems of continuous sorting, increase the difficulty of delivery inventory, and not close together, so as to shorten the delivery time , reduce equipment configuration, reduce the effect of land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

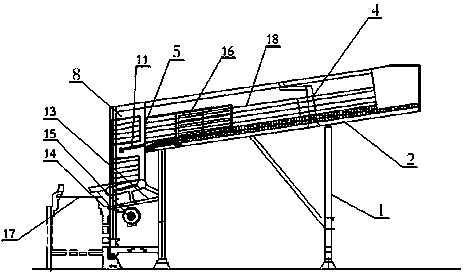

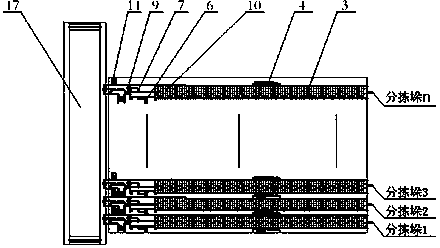

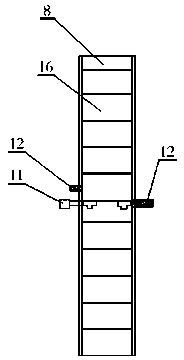

[0026] The front view of the high-speed replenishment continuous sorting device for regular objects of the present invention is as follows figure 1 said, figure 2 Shown the top view of this device, the high-speed replenishment continuous sorting device of the regular object of the present invention comprises frame 1, is provided with the storage bin 2 of oblique arrangement on frame 1, and storage bin 2 is provided with guardrail 18, and described regular object It is a pile-shaped object 16. A roller bar 3 installed in a misplaced position is installed at the bottom of the storage bin 2. A shaping mechanism 4 with a notched baffle is provided at the lower end of the storage bin 2 entrance so that the guardrail 18 can pass through front and back. The stacked object 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com