An edge shielding device of the cooling system after medium and heavy plate rolling

A shielding device and cooling system technology, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve problems such as difficult maintenance, broken chains, and simple structure of chain edge shielding devices, and achieve simple device structure , Safe and reliable operation, and the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

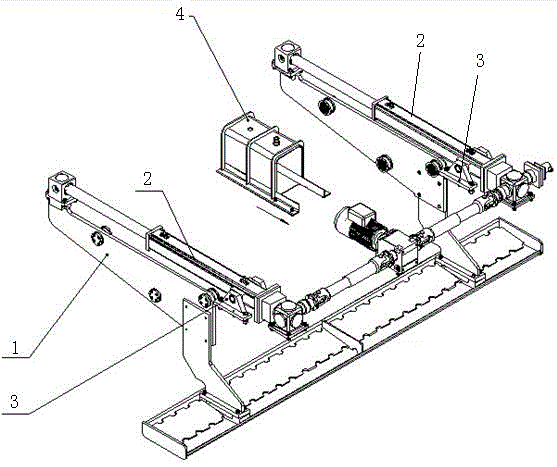

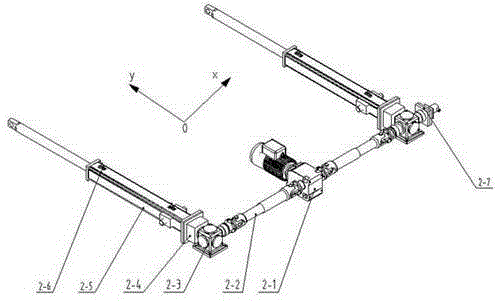

[0016] see figure 1 , the edge shielding device of the medium and heavy plate post-rolling cooling system of the present invention includes a unit shielding bracket assembly 1, an electric cylinder linkage assembly 2, a push rod support assembly 3 and a motor shield assembly 4; the unit shielding bracket assembly 1 is connected by bolts On the electric cylinder linkage assembly 2, it can be connected with the bolts to the cylinder body and the power group rod 2-5 of the electric cylinder linkage assembly 2 (see image 3 ) stretches and moves. The push rod end of the electric cylinder linkage assembly 2 is fixedly connected to the bracket assembly 1 , and the cylinder end of the electric cylinder linkage assembly 2 is connected to the push rod support assembly 3 .

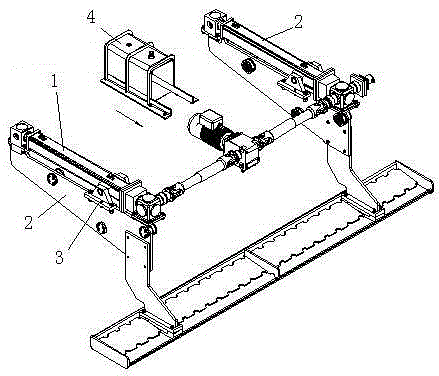

[0017] figure 1 , the push rod of the electric cylinder linkage assembly 2 is in the extended state, and figure 2 in the state of income.

[0018] image 3 It is a structural diagram of the electric cylinder l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com