Multifunctional filter unit

A filter device and multi-functional technology, applied in the direction of filtration separation, fixed filter element filter, foam dispersion/prevention, etc., can solve the problems of unguaranteed product quality, high production cost, slow production speed, etc., to facilitate mass production , low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

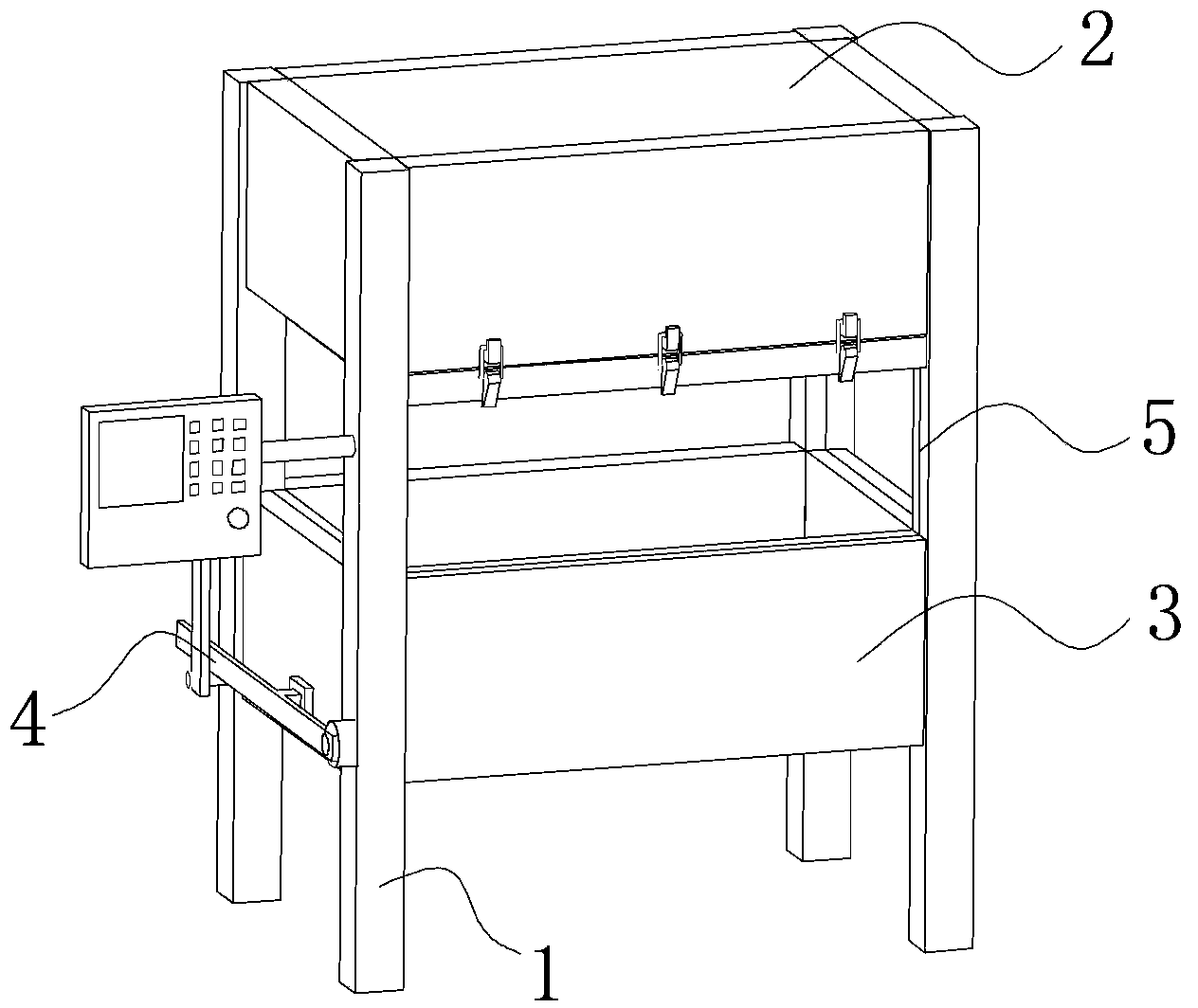

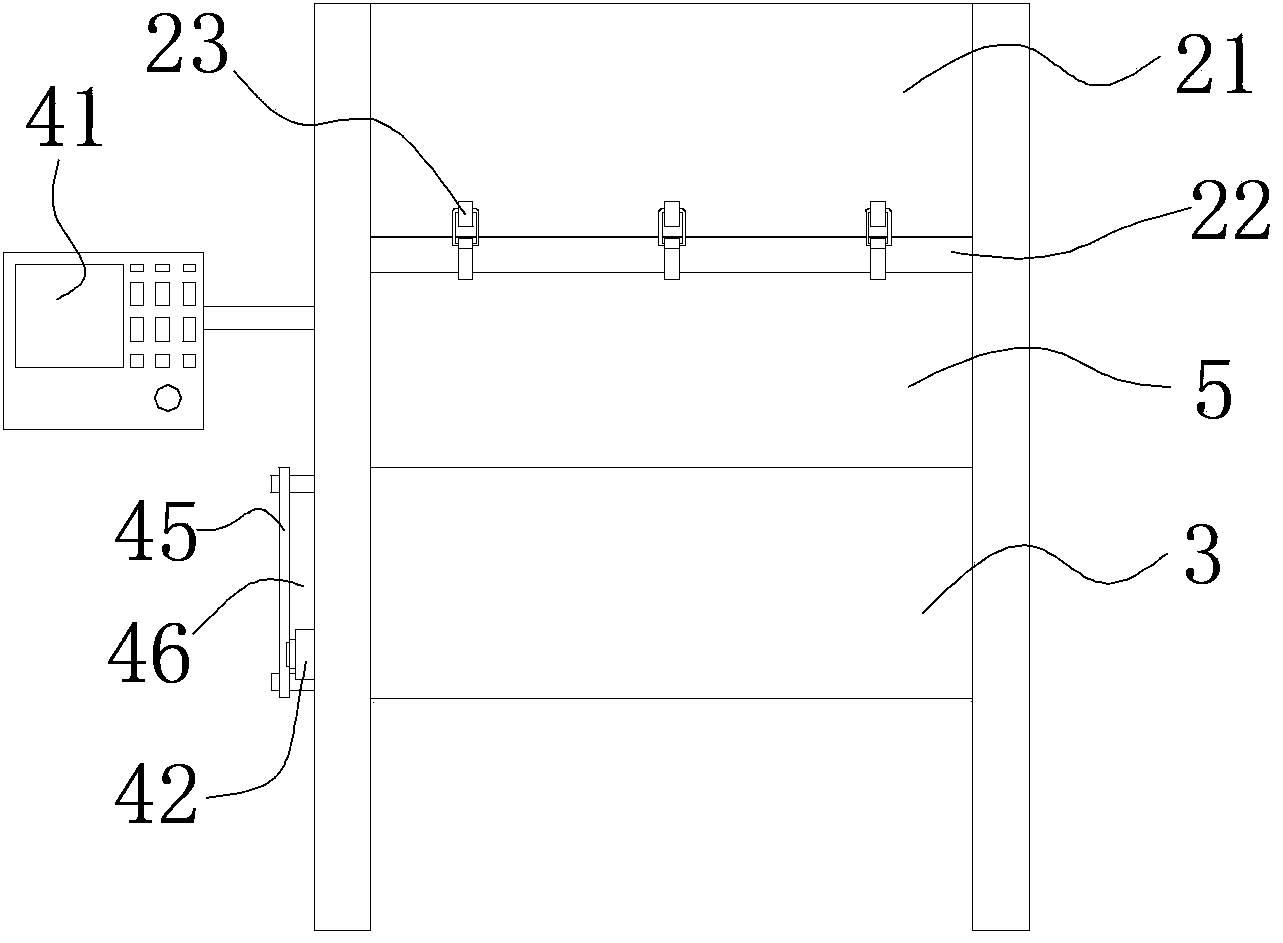

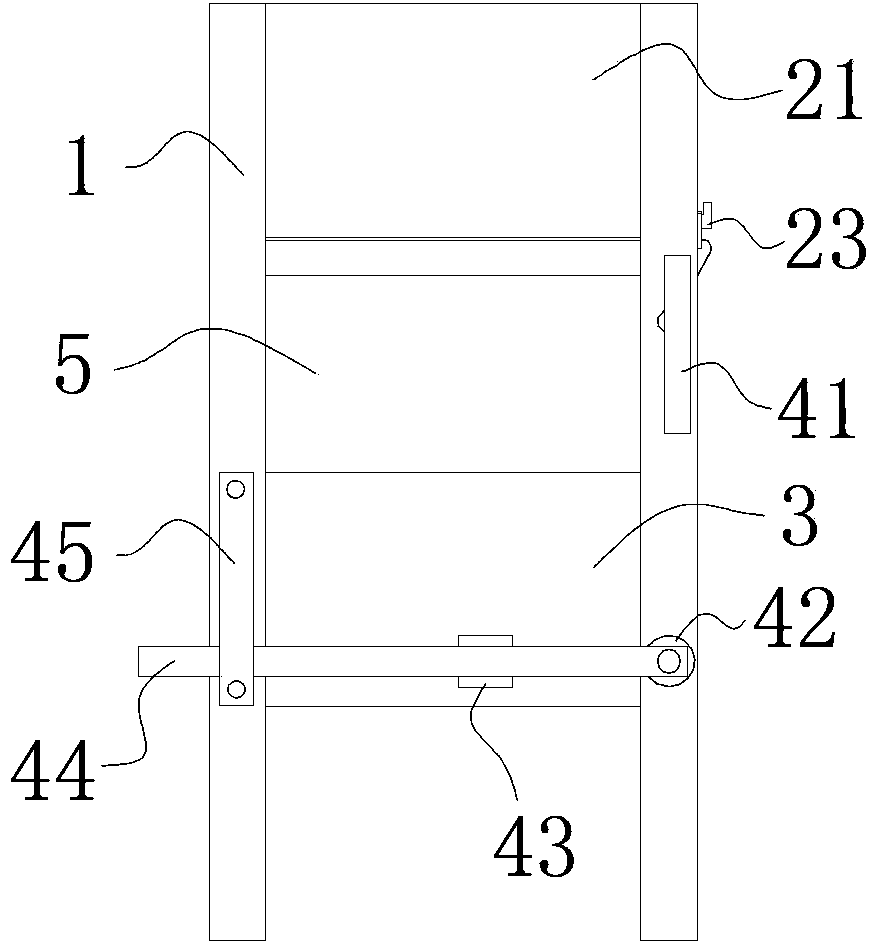

[0015] Example: see figure 1 , figure 2 and image 3 , a multifunctional filter device provided in this embodiment, which includes a frame 1, a filter assembly 2 is provided on the top of the frame 1, and a defoaming assembly 3 is provided at a certain distance directly below the filter assembly 2, The bottom of the side wall of the defoaming component 3 is provided with a discharge port, and an automatic discharge mechanism 4 that can seal or open the discharge port is provided on the side wall. It also includes a transparent protective cover 5, the transparent protective cover 5 is arranged between the filter assembly 2 and the defoaming assembly 3, which ensures the airtightness of the equipment, prevents moisture and dust, further improves the quality of the product, and is convenient for monitoring the equipment. working process. The filter assembly 2 includes a box body 21 with an opening at the bottom, a bottom frame 22 and a filter screen arranged on the bottom fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com