Improved method of detecting wear of a tyre

A tire and tread pattern technology, applied in tire measurement, tire parts, tire tread/tread pattern, etc., can solve problems such as false warnings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

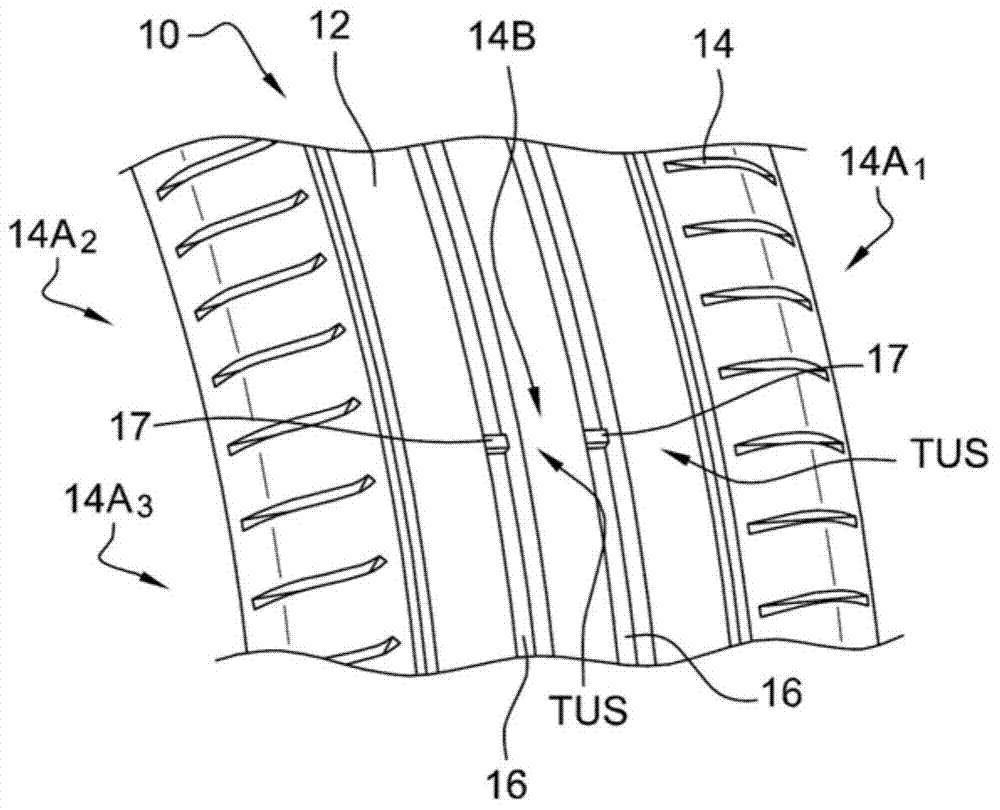

[0053] image 3 The tire is shown in a new condition, indicated by the general reference numeral 10 . The tire 10 is for a passenger vehicle. Tire 10 is essentially a solid body of rotation about an axis.

[0054] Tire 10 includes a tread 12 of substantially annular shape 12 having a tread pattern 14 on its outer surface. The tread pattern includes a first tread pattern element 14A and a second tread pattern element 14B.

[0055] The first tread pattern element 14A comprises circumferentially distributed circumferential portions 14A around an axis of rotation. 1 ,14A 2 ,14A 3 ,...,14A 75 , in this case number seventy-five. 14A per part i With the choice of patterns from a group of several different patterns (typically three or four patterns). The first element 14A comprises two parallel circumferential grooves 16 cut into the surface of the tire, the circumferential grooves 16 having a predetermined depth H when the tire 10 is new. Therefore, each section 14A i A ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com