Fuse assembly

一种熔断器、组件的技术,应用在电气元件、电路、紧急保护装置等方向,能够解决不利影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described by way of embodiments with reference to the accompanying drawings.

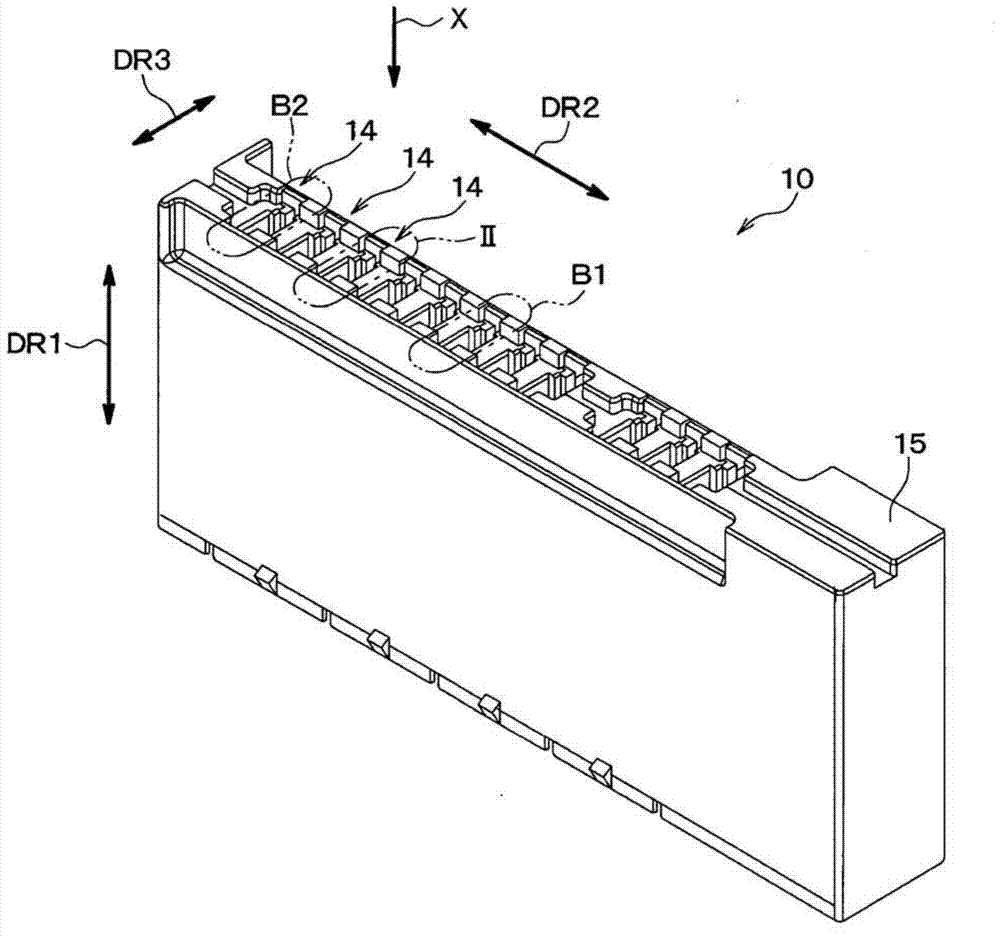

[0031] Such as Figure 1A As shown, the electrical connector box 10 has a plurality of fuse mounting portions 14, a fuse subassembly 12 (shown in Figure 6 and Figure 7A to Figure 7D ) mounted to each fuse mounting section 14. For example, the electrical connector box 10 is a fuse box for a vehicle, or a relay box having a plurality of fuse mounting parts 14 and electronic parts and / or components (for example, relays). For example, the electrical connector box 10 is installed in an engine room of a vehicle. The housing 15 forming a part of the housing of the electrical connector box 10 is made of resin such as PBT resin, PP resin, or the like.

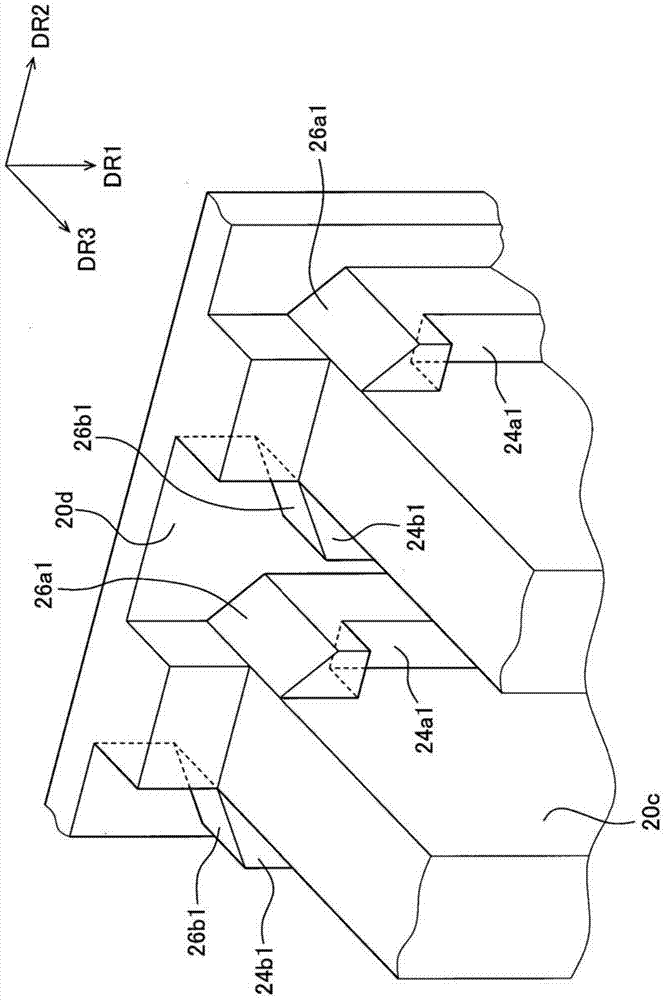

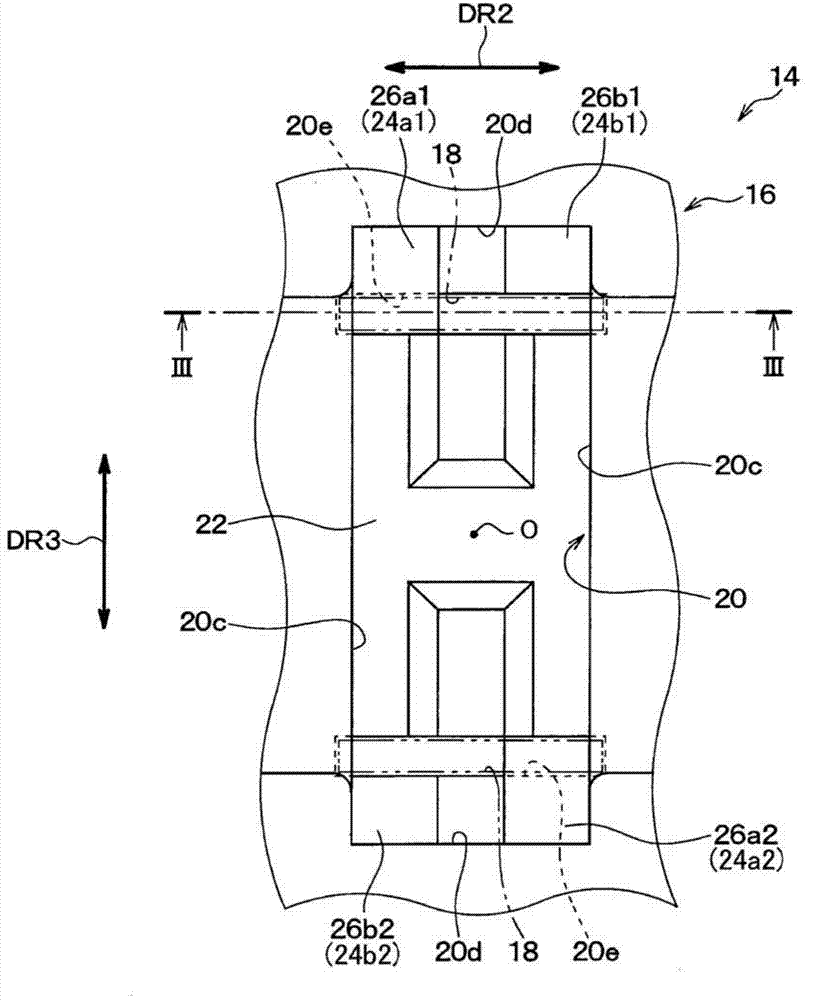

[0032] The structure of the fuse mounting portion 14 of the electrical connector box 10 will be described. Although the electrical connector box 10 has a plurality of fuse mounting portions 14 arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com