Sealed formation testing process of high hydrogen sulfide well

A technology with high hydrogen sulfide content and process flow, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling and production, etc., can solve the problems of increased operating costs, increased dosage of injection chemicals, affecting flowback and oil well production, etc. Achieve the effect of improving production timeliness, ensuring life safety, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

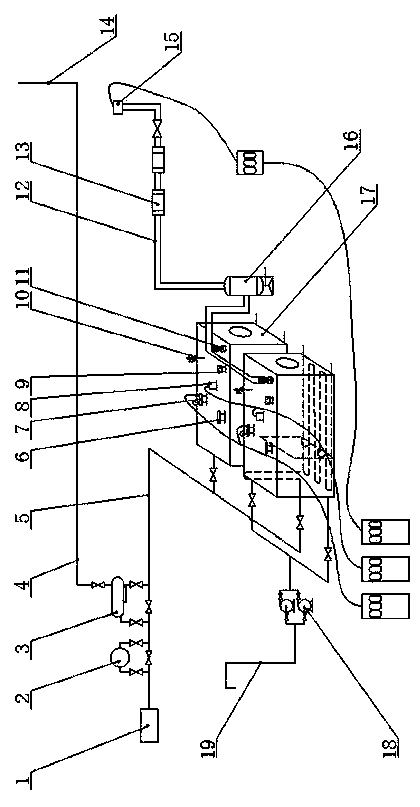

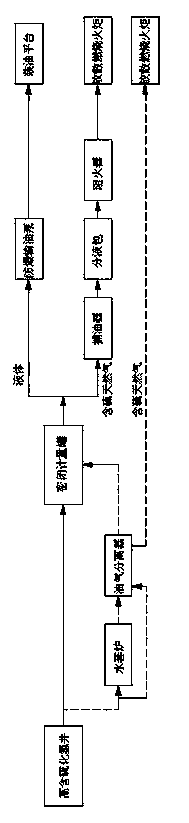

[0011] Example: such as figure 1 , 2 As shown, the closed oil testing process of high hydrogen sulfide wells includes two parts: on-site installation process and on-site oil testing process. Furnace (2), oil-gas separator (3). The gas outlet of the oil-gas separator (3) is divided into two paths, one path is connected to the installation clamp gate valve, the separator exhaust pipeline (4) to the ignition torch (14), and the other path is connected to the installation fluid delivery pipeline (5), the clamp gate valve to the Seal the oil inlet of the metering tank (17). The oil outlet of the airtight metering tank (17) is connected with the clamp gate valve and the explosion-proof oil delivery pump (18) to the oil loading platform (19). The exhaust port of the airtight metering tank (17) is installed and connected to the flanged gate valve, oil trap (11), liquid separation bag (16), exhaust pipeline (12), flame arrester (13), flanged gate valve to the venting combustion torc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com