Hinged rectangular-pipe assembled buckling restrained brace with end rotation limiting function

A kind of anti-buckling bracing and prefabricated technology, applied in the direction of anti-vibration, building components, etc., can solve the problems of high production precision, increased production cost, poor durability, etc., and achieve the effect of convenient precision control, easy production thickness, and easy processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

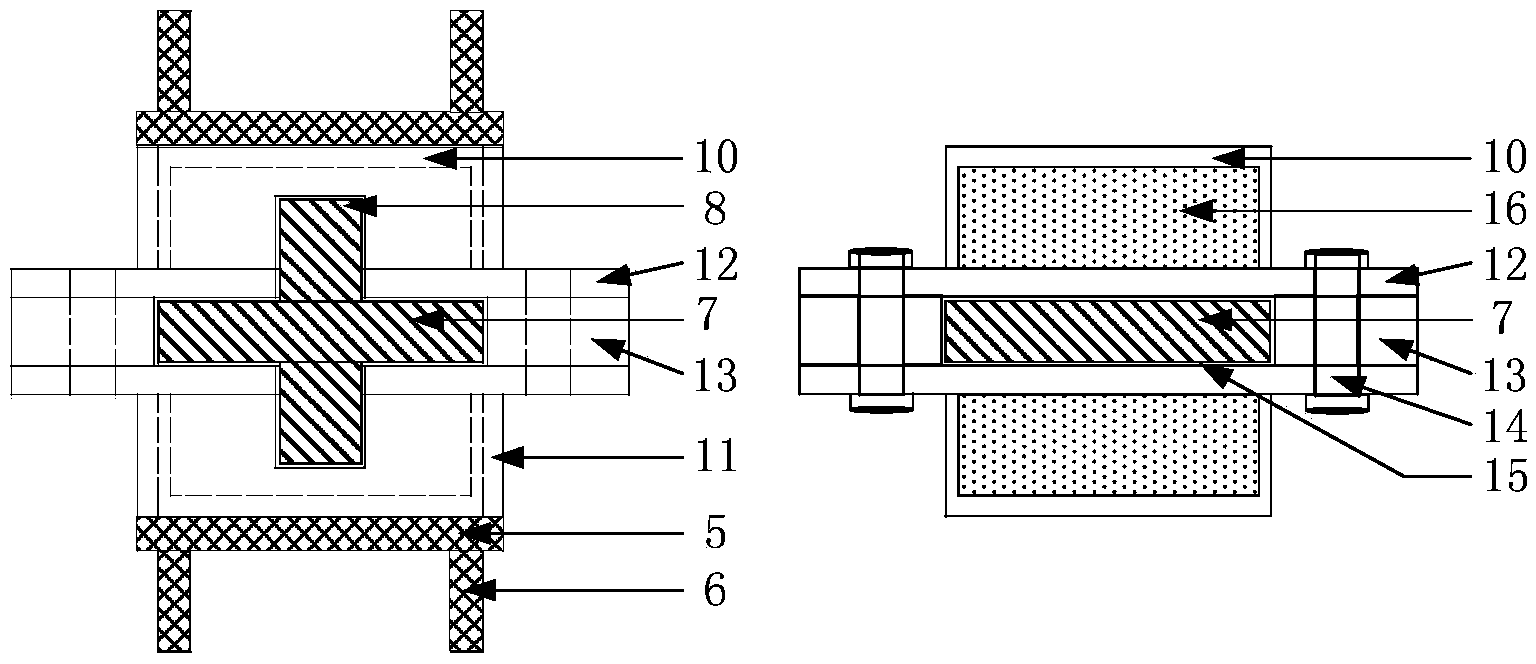

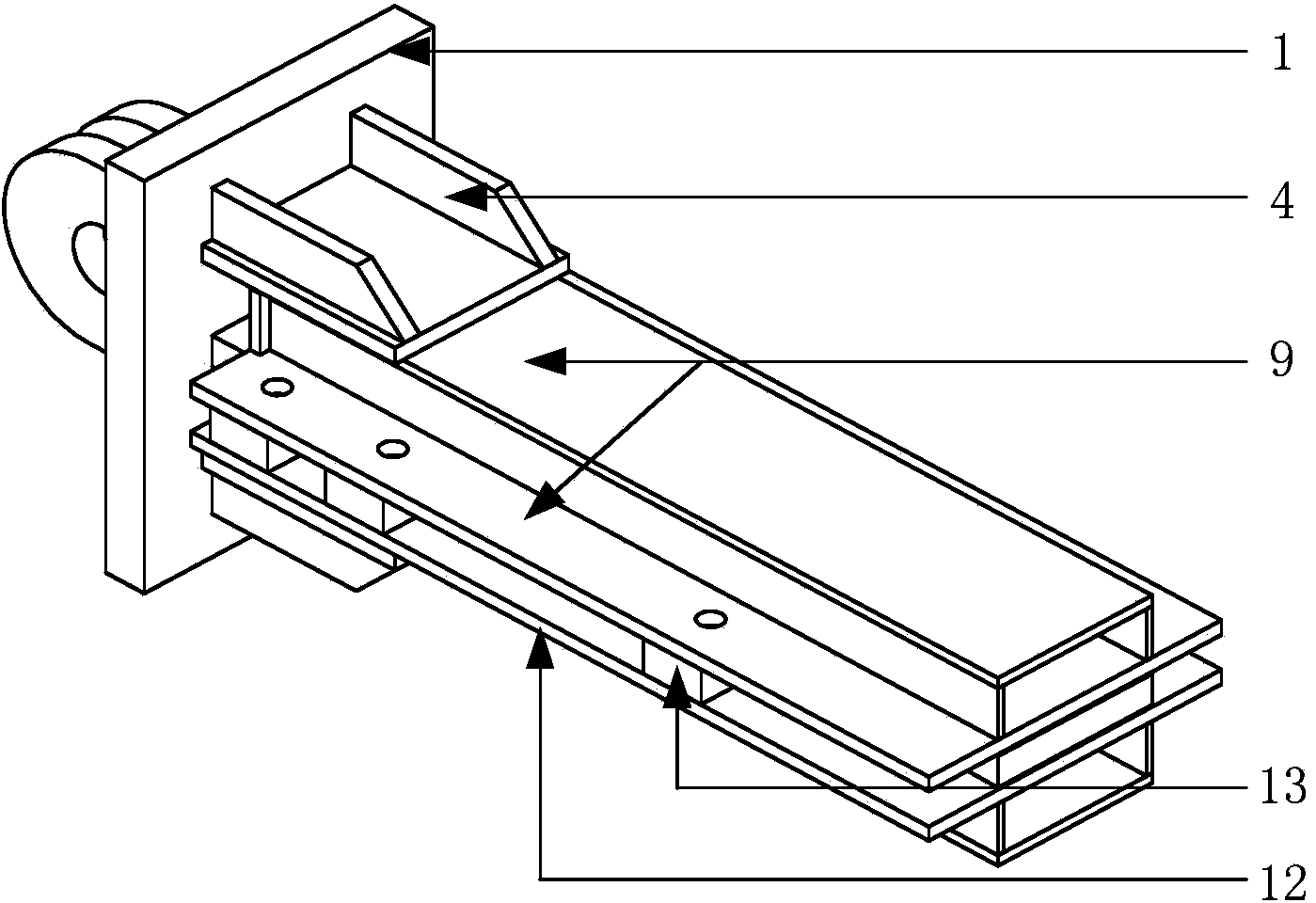

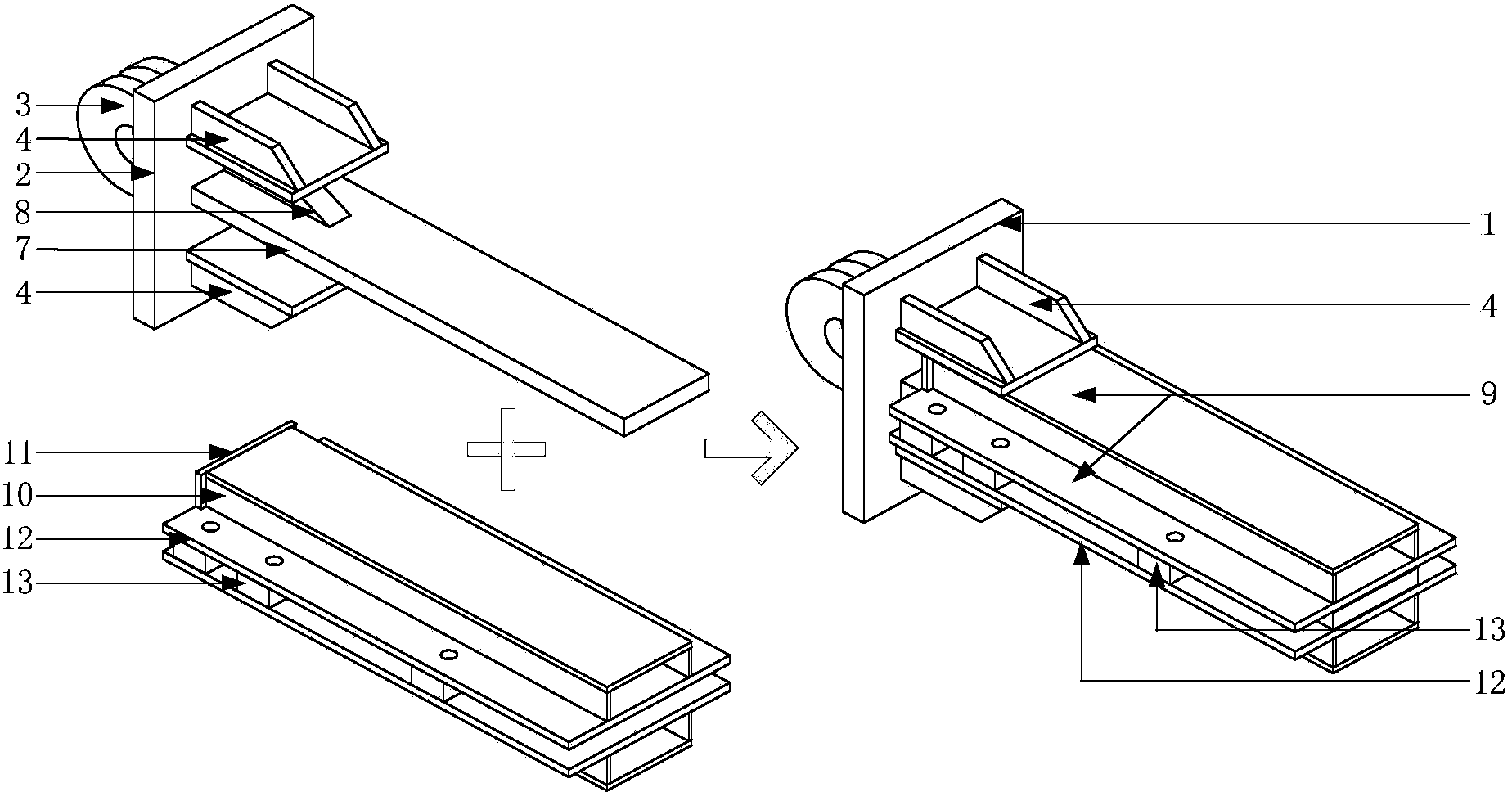

[0024] In the present invention, upper and lower wings are added to the end of the in-line inner core member to form a reinforced section of the inner core member; the reinforced section of the inner core member is divided into two types: the extended section and the restraint section, and the length of the reinforced restraint section of the inner core member should ensure that the support is under the action of the axial tension load. There is still a certain length below.

[0025] At the same time, in order to meet the requirement of free expansion and contraction of the reinforcement section of the inner core member in the longitudinal direction, the end of the flat steel plate constraining the square steel pipe is grooved, and the groove is locally reinforced, and the length of the reinforcement is consistent with the length of the groove; the end of the outer restraint member The local reinforcement at the center is mainly realized by setting the outer cover plate of chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com