Low-water-absorption-rate expansion vibration-damping glue

A technology of expansion damping rubber and low water absorption, which is applied in the field of expansion damping rubber, which can solve problems such as aging of vibration damping rubber, affecting beautification, corrosion of steel plates, etc., to achieve the effect of preventing rainwater corrosion, low water absorption, and ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

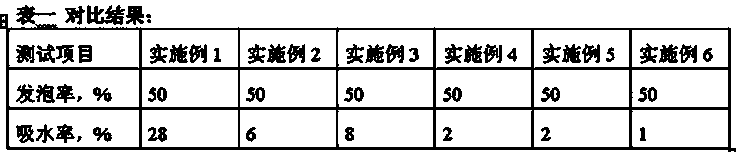

Examples

Embodiment 1

[0071] Example 1 (comparative example): 20 parts of Polyoil 110, 4 parts of butadiene rubber (solid), 10 parts of phenyl sulfonate, 7 parts of maleic anhydride modified polybutadiene, 4 parts of sulfur, accelerator DM 1.5 parts, 0.5 parts of antioxidant 2246, 1.4 parts of calcium oxide, 1.4 parts of zinc oxide, 2 parts of 4,4'-oxobisbenzenesulfonyl hydrazide (OBSH), 0.2 parts of carbon black, 22 parts of surface-treated calcium carbonate, Calcium carbonate 26 parts.

Embodiment 2

[0072] Example 2: 20 parts of Polyoil 110, 4 parts of styrene-butadiene rubber (solid), 10 parts of phenyl sulfonate, 7 parts of maleic anhydride modified polybutadiene, 4 parts of sulfur, 1.5 parts of accelerator DM, anti- 0.5 parts of oxygen agent 2246, 1.4 parts of calcium oxide, 1.4 parts of zinc oxide, 2 parts of 4,4'-oxobisbenzenesulfonyl hydrazide (OBSH), 0.2 parts of carbon black, 6 parts of polypropylene micropowder, 22 parts of surface-treated calcium carbonate Parts, 20 parts of calcium carbonate.

Embodiment 3

[0073] Example 3: 20 parts of Polyoil 110, 4 parts of butadiene rubber (solid), 10 parts of phenyl sulfonate, 7 parts of maleic anhydride modified polybutadiene, 4 parts of sulfur, 1.5 parts of accelerator DM, anti- 0.5 parts of oxygen agent 2246, 1.4 parts of calcium oxide, 1.4 parts of zinc oxide, 2 parts of 4,4'-oxobisbenzenesulfonyl hydrazide (OBSH), 0.2 parts of carbon black, 6 parts of polyethylene micropowder, 18 parts of surface-treated calcium carbonate parts, calcium carbonate 20 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com