Substrate processing line and substrate processing method

A substrate processing and substrate technology, which is applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve the problems that the substrate cannot be supported, and the movement of the movable conveyor belt cannot be carried out at any time, so as to achieve the effect of inhibiting movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

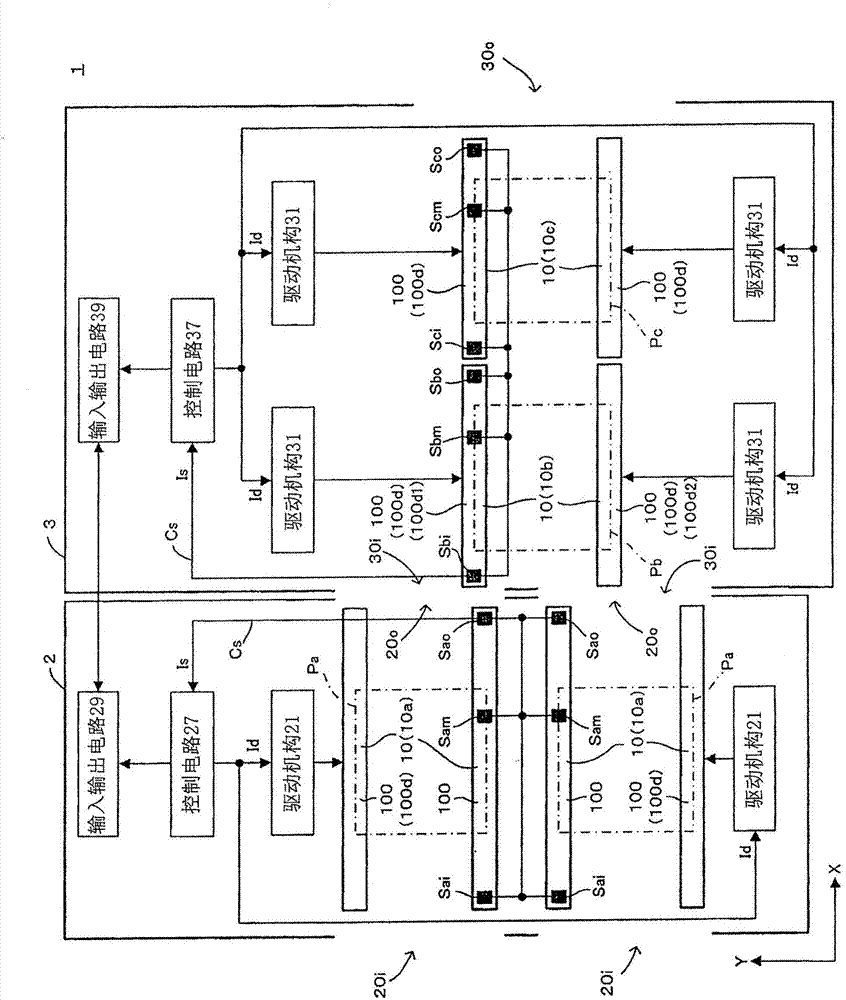

[0020] figure 1 It is a figure which schematically shows an example of the substrate processing line concerning 1st Embodiment of this invention. In this figure and the figures shown below, the XY orthogonal coordinate axes which set the board|substrate conveyance direction as the X-axis direction, and the direction orthogonal to the X-axis direction as the Y-axis direction are shown suitably. In this substrate processing line 1, a plurality of (two) substrate processing apparatuses 2 and 3 (a plurality of processing apparatuses) are arranged (arranged) in sequence along the substrate conveying direction X, and the substrate A is conveyed along the substrate conveying direction X ( Figure 4 ), and the substrate A is subjected to specified processing in each of the substrate processing apparatuses 2 and 3 .

[0021] In the substrate processing line 1, the substrate processing apparatus 2 (another processing apparatus, that is, the second processing apparatus) arranged on the ...

no. 2 approach >

[0070] Figure 7 It is a figure which schematically shows an example of the substrate processing line concerning 2nd Embodiment of this invention. The substrate processing line 1 of the second embodiment differs from the substrate processing line 1 of the first embodiment in that the arrangement of the substrate processing apparatuses 2 and 3 is reversed from that of the first embodiment. Therefore, the detailed structure of each of the substrate processing apparatuses 2 and 3 is the same as that described above in the first embodiment, and description thereof will be appropriately omitted here.

[0071] In the substrate processing line 1 of the second embodiment, two substrate processing apparatuses 3 and 2 are arranged sequentially along the substrate conveyance direction X, and the substrate A is conveyed along the substrate conveyance direction X, and the substrate A is processed in each of the substrate processing apparatuses 3 and 2 . In such a substrate processing lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com