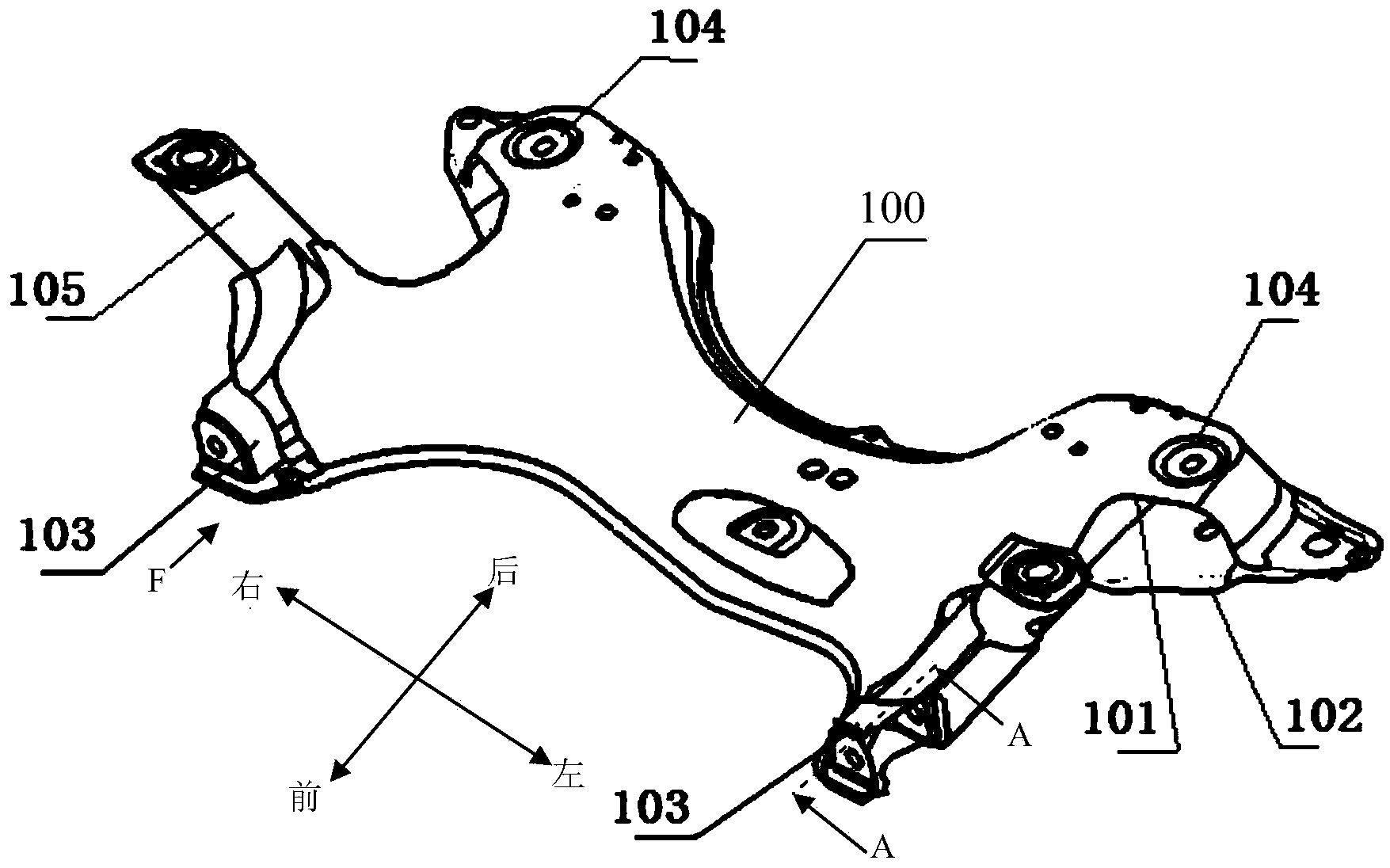

Front auxiliary frame

A front subframe and front side member technology, which is applied to vehicle components, substructures, transportation and packaging, etc., can solve the problems of bracket deformation welding stress, concentration, failure to form an ideal front and rear double-layer reinforcement structure, etc. The effect of force strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

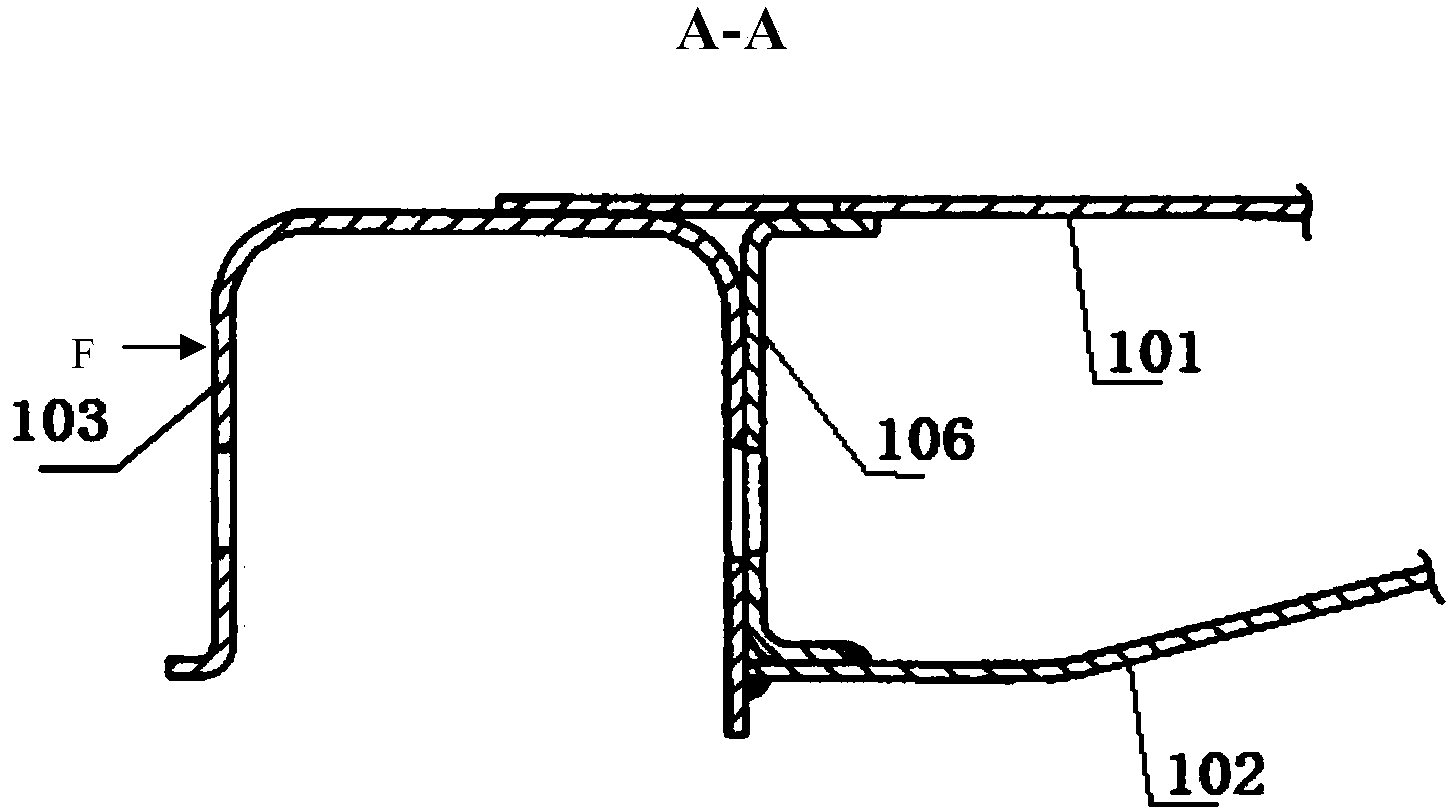

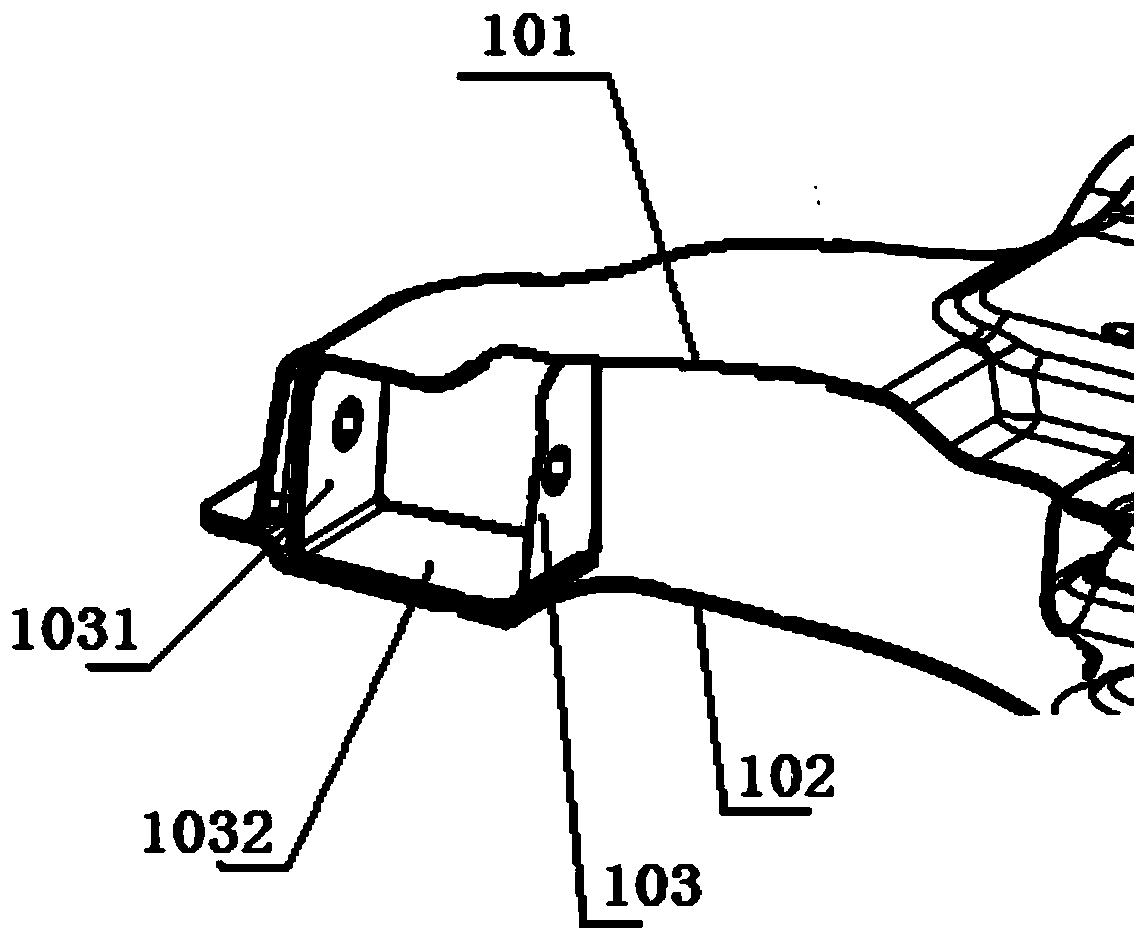

[0031] refer to Figure 5 , it can be seen that the front side member 105 and the front mounting bracket 103 are integrally stamped and formed. Front mounting bracket 103 has front side wall 1031, bottom wall 1032 and rear side wall 1033, and for front side member 105, it has a common wall portion 1033 with front mounting bracket 103, and this wall 1033 and front side member 105 The other side wall 1053 of the front side member 105 and the bottom wall 1054 of the front side member 105 jointly form a groove structure. Moreover, the upper end cover 1051 of the front side member 105 is used to realize connection with the vehicle body, and the lower end 1052 has a flange structure for realizing welding with the lower plate 102 . A boss 1034 is also stamped on the rear side wall 1033 . In addition, under the upper end cover 1051 , a backing plate 1056 is welded between the side wall 1033 and the side wall 1053 of the front side member 105 , and the backing plate 1055 and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com