Guide belt correcting device of rotary screen printing machine

A technology of rotary screen printing and deviation correction device, applied in the textile field, can solve the problems of unfavorable production, shutdown, complex structure, etc., and achieve the effect of simple detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

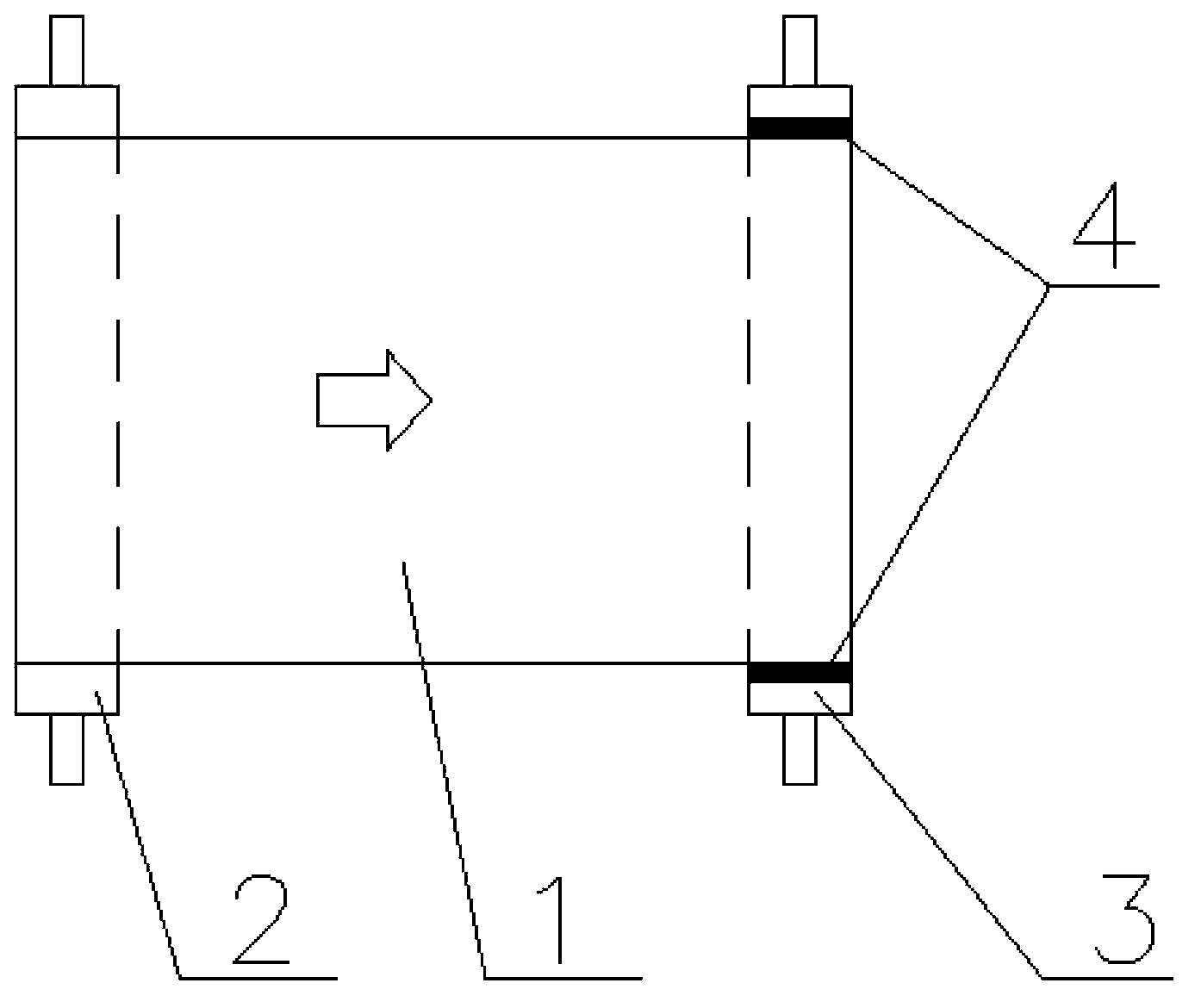

[0017] Such as figure 1 Shown is a guide belt deviation correction device for a rotary screen printing machine, which includes a guide belt 1, a tension roller 2, a drive roller 3, a deviation correction motor, a camera and a controller. The guide belt 1 is stretched between the tension roller 2 and the drive roller 3, and driven by the driving roller 3, the outer surface of the driving roller 3 or the tension roller 2 is provided with a colored coating 4; during normal operation, the colored coating 4 protrudes from both sides of the guide belt 1, and will be colored at this time. The coating 4 protrudes two widths on both sides of the conduction band 1 as the standard width;

[0018] The camera collects the images of both sides of the colored coating 4 protruding from the guide belt 1 in real time, and transmits the images collected in real time to the controller; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com