Quick cooling temperature control injection molding mold

An injection mold and rapid cooling technology, which is applied in the field of molds, can solve the problems of long pouring runners and heat preservation shapes, affecting the pouring amount of materials, etc., and achieve the effects of improving quality, increasing capacity, and enhancing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

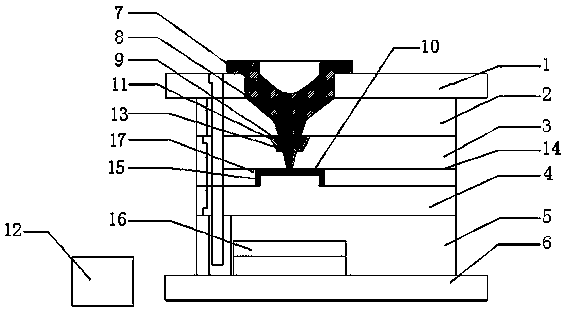

[0013] Such as figure 1 As shown, a rapid cooling temperature-controlled injection mold includes an upper fixed template 1, a stripper plate 2, a female template 3, a male template 4, a lower fixed template 5 and a bottom plate 6, and the stripper plate 2 is fixed on the top of the upper fixed template 1. Below, the female formwork 3 is fixed below the stripper plate 2, the male formwork 4 is fixed on the lower fixed formwork 5, the lower fixed formwork 5 is fixed on the bottom plate 6, and the upper fixed formwork 1 is provided with a guide trough 7, and the bottom of the guide trough 7 A flow channel 8 is communicated, a groove 9 is provided on the master template 3, the flow channel 8 communicates with the groove 9, a cavity 10 is connected at the bottom of the groove 9, and a heating device 11 is arranged outside the groove 9. The device 11 is connected with a control device 12 , and a temperature sensor I13 is arranged on one side of the outer wall of the groove 9 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com