A Cube-Rod Mechanism Realizing the Rotation of Ball-like Joints with Three Degrees of Freedom in Space by Linear Drive

A linear drive, degree of freedom technology, applied in the field of robotics, can solve problems such as complex calculations and poor decoupling, and achieve the effects of improved motion performance, light structure, and convenient motion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

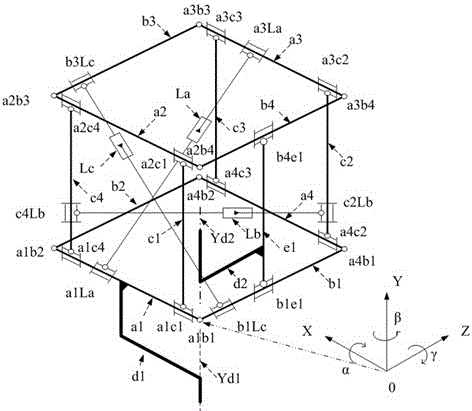

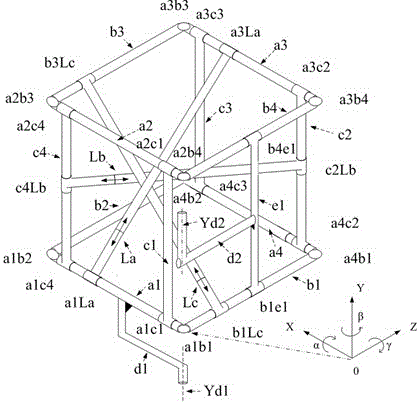

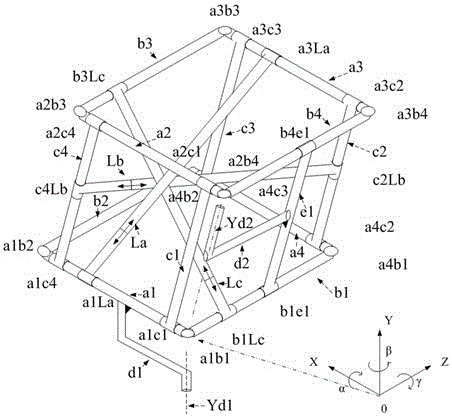

[0032] combine figure 1 , 2 , 3. This embodiment is a linear drive to realize the three-degree-of-freedom spherical joint rotation of the cube rod mechanism, including: coordinate system XYZ, ball joint angle αβγ, X-axis first rigid body a1, X-axis second rigid body a2, X-axis third rigid body a3, X-axis fourth rigid body a4, Y-axis first rigid body c1, Y-axis second rigid body c2, Y-axis third rigid body c3, Y-axis fourth rigid body c4, Z-axis first rigid body b1, Z Axis second rigid body b2, Z axis third rigid body b3, Z axis fourth rigid body b4, first base d1, second base d2, auxiliary rigid body e1, first telescopic rod La, second telescopic rod Lb, third Telescopic rod Lc, first hinge point a1b1 on XZ1 plane, second hinge point a4b1 on XZ1 plane, third hinge point a4b2 on XZ1 plane, fourth hinge point a1b2 on XZ1 plane, first hinge point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com