A marking hole drilling jig for plunger

A marking and hole drilling technology, applied in the direction of drilling dies, clamping, and manufacturing tools for workpieces, can solve the problems of affecting processing efficiency, increasing labor intensity, time-consuming and laborious, etc., to reduce labor intensity, improve processing efficiency, Precisely positioned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

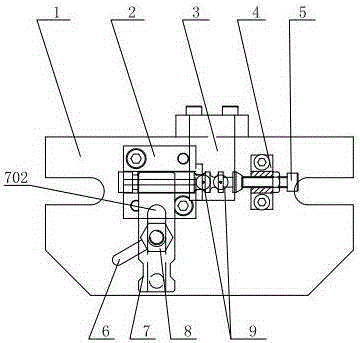

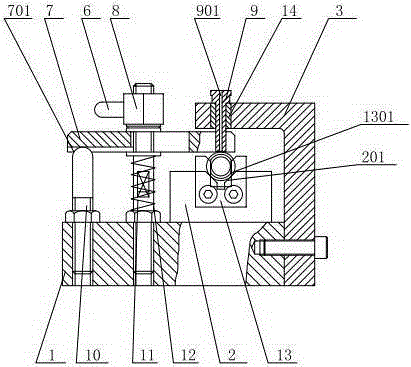

[0018] Such as figure 1 , figure 2 As shown, a marking hole drilling jig for plunger parts includes a bottom plate 1, one end of a double-ended screw 12 is screwed to the bottom plate 1 and locked by a nut (not shown in the figure), and the other end penetrates the pressure plate 7 And be screwed in locking nut 8, locking nut 8 is welded with locking handle 6, in the bottom of pressing plate 7, be positioned at the outer periphery of double-ended screw rod 12 and also sleeve spring 11. Have groove 701 and waist-shaped hole 702 on pressing plate 7; Be positioned at the side of double-ended screw rod 12, also install top post 10 on bottom plate 1, one end of top post 10 stretches out bottom plate 1 and opens with pressing plate 7 Groove 701 abuts; drill sleeve positioning plate 3 is installed on one side of base plate 1, drill sleeves 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com