Welding gun regulating device applied to welding of horizontal H-shaped steel

An adjustment device, H-beam technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult to guarantee the position accuracy of the welding torch, slow adjustment speed, etc., and achieve the effect of wide application and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the drawings:

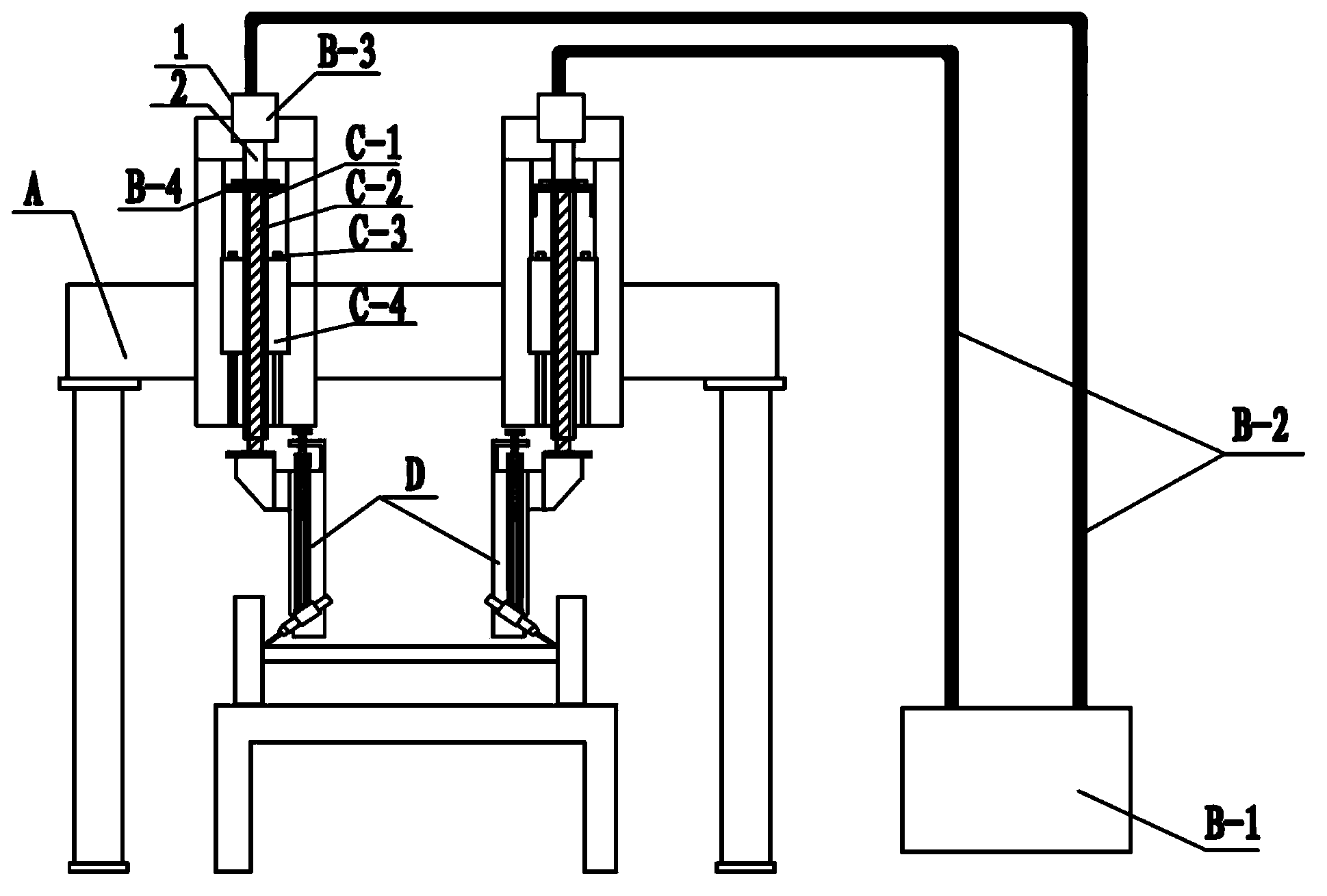

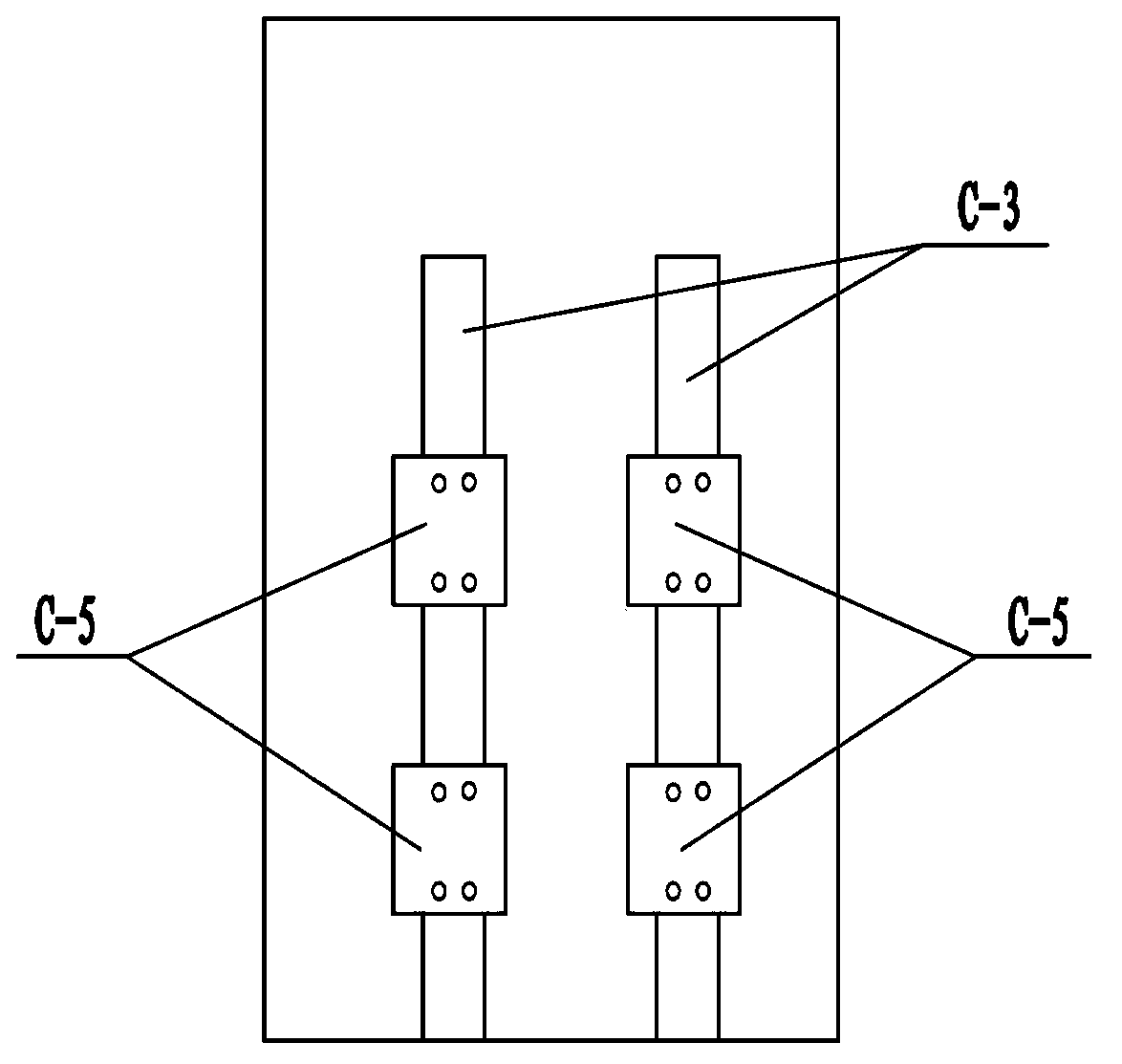

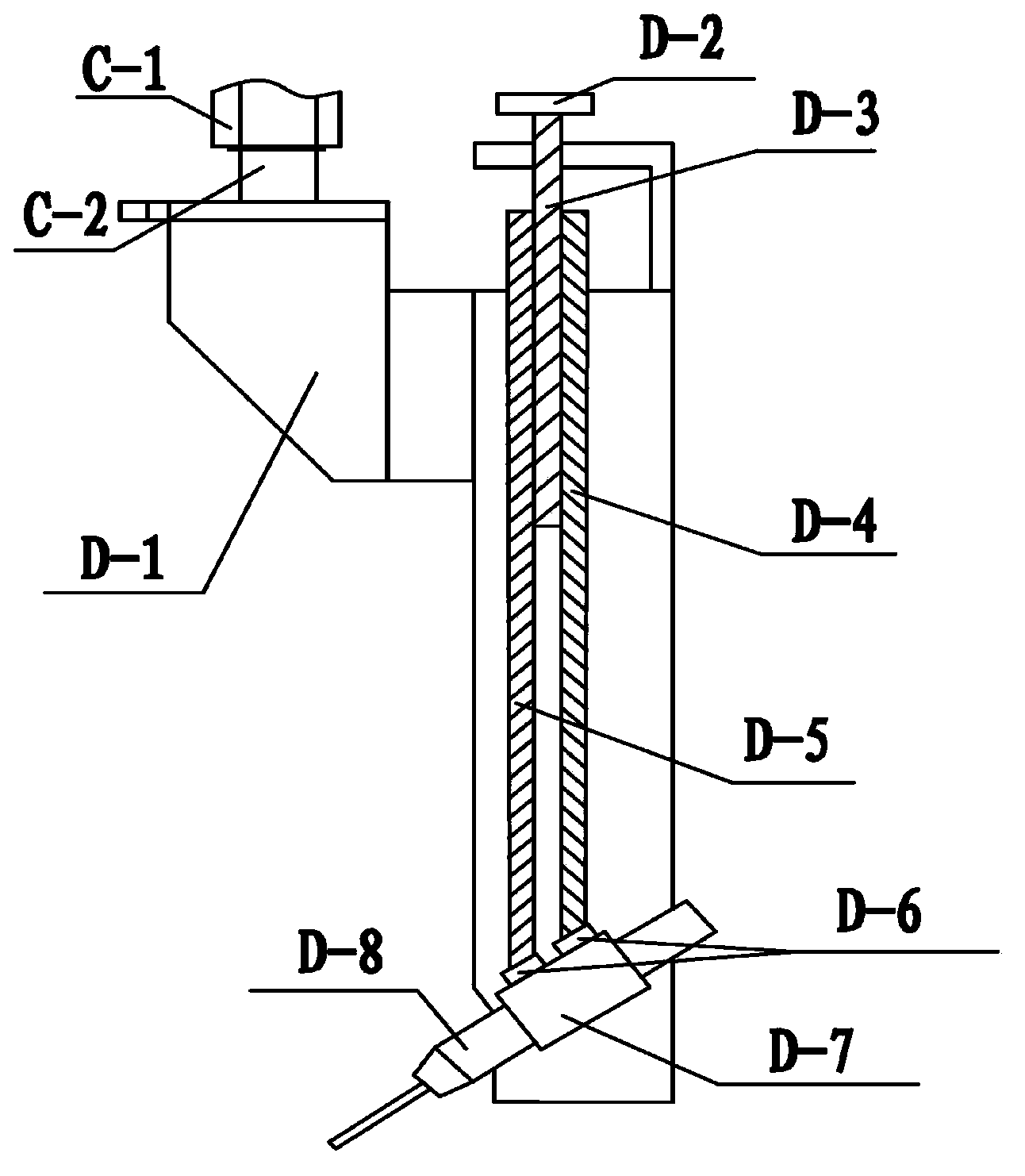

[0016] The present invention is a welding gun adjusting device for horizontal welding of H-shaped steel, which is composed of a frame, a hydraulic pushing device and a welding gun adjustable mechanism. The hydraulic pushing device B is composed of hydraulic station B-1, oil pipe B-2, and hydraulic cylinder B- 3 composition, through the control of the hydraulic station to automatically pressurize and release the pressure, the cylinder liner 1 of the hydraulic cylinder B-3 is connected to the frame A, the welding gun adjustable mechanism C is composed of a lifting mechanism and a rotating mechanism, the lifting mechanism It is composed of a lifting platform C-4, a running slide C-3, and a pin sleeve C-1. The running slide C-3 is longitudinally installed on the frame A, and the welding gun lifting platform C-4 runs through the slider C-5. The slide rail C-3 cooperates to slide up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com