A small-diameter tube extrusion welding device

A small-diameter tube and welding sealing technology, which is applied in the direction of auxiliary devices, welding equipment, tubular objects, etc., can solve the problems of technical specific method introduction, less extrusion welding sealing technology, etc., and achieve the problem of solving the implementation method, complete functions, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

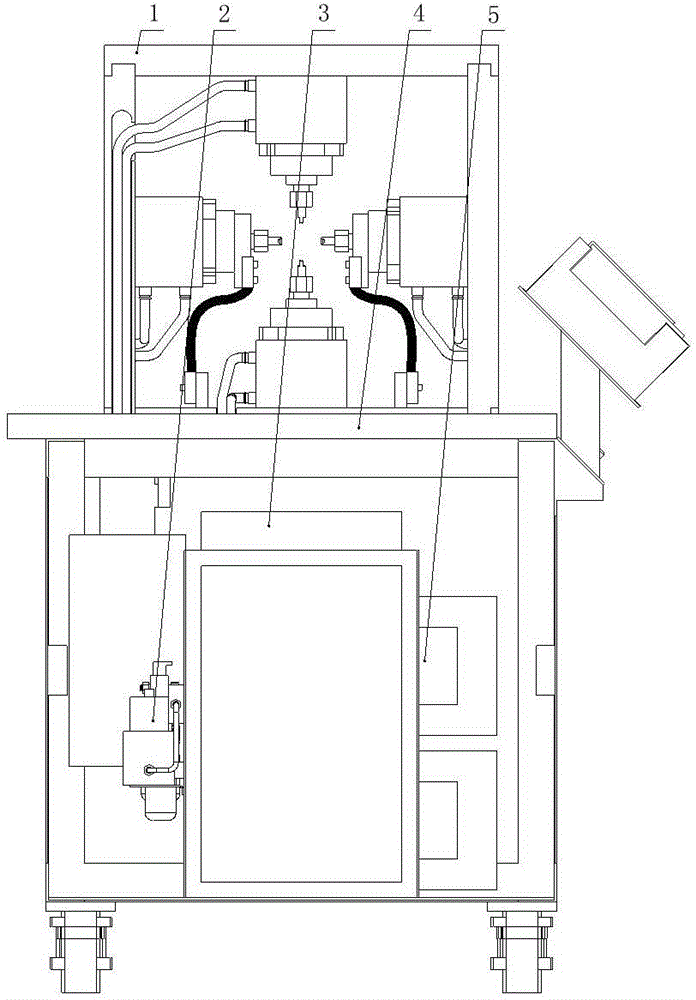

[0024] Such as figure 1 As shown in , a small-diameter tube extrusion welding device of the present invention includes a welding head 1, an air circuit system 2, a welding power supply 3, a support control cabinet 4, and a control system 5; a welding head 1 and an air circuit system 2 , Welding power supply 3, and control system 5 are all fixedly installed on the support control cabinet body 4, and the support control cabinet body 4 is equipped with casters and can be moved.

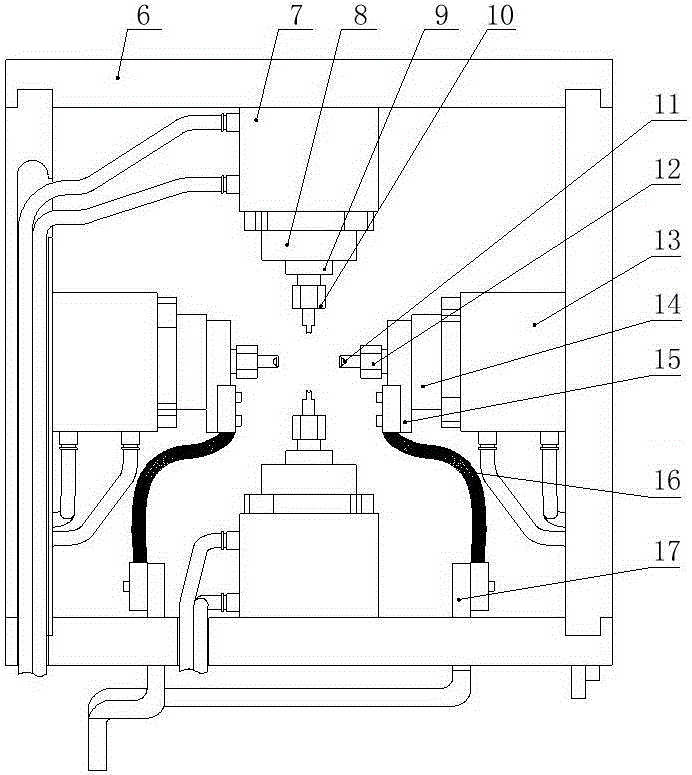

[0025] Such as figure 2 As shown in , the welding head 1 includes a welding head frame 6, a limit mold cylinder 7, a limit mold insulating support plate 8, a limit mold quick change seat 9, a limit mold nut 10, a welding tool 11, Welding electrode nut 12, welding electrode cylinder 13, welding electrode insulating support seat 14, welding electrode quick-change seat 15, conductive soft copper strip 16, conductive hard copper strip 17; welding head frame 6 is a "mouth" shaped frame body, for The limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com