a line management mechanism

A wire management and tie rod technology, applied in assembly machines, lighting and heating equipment, sorting and other directions, can solve problems such as non-occurrence, and achieve the effects of energy saving, simple structure and function implementation, and reduced floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

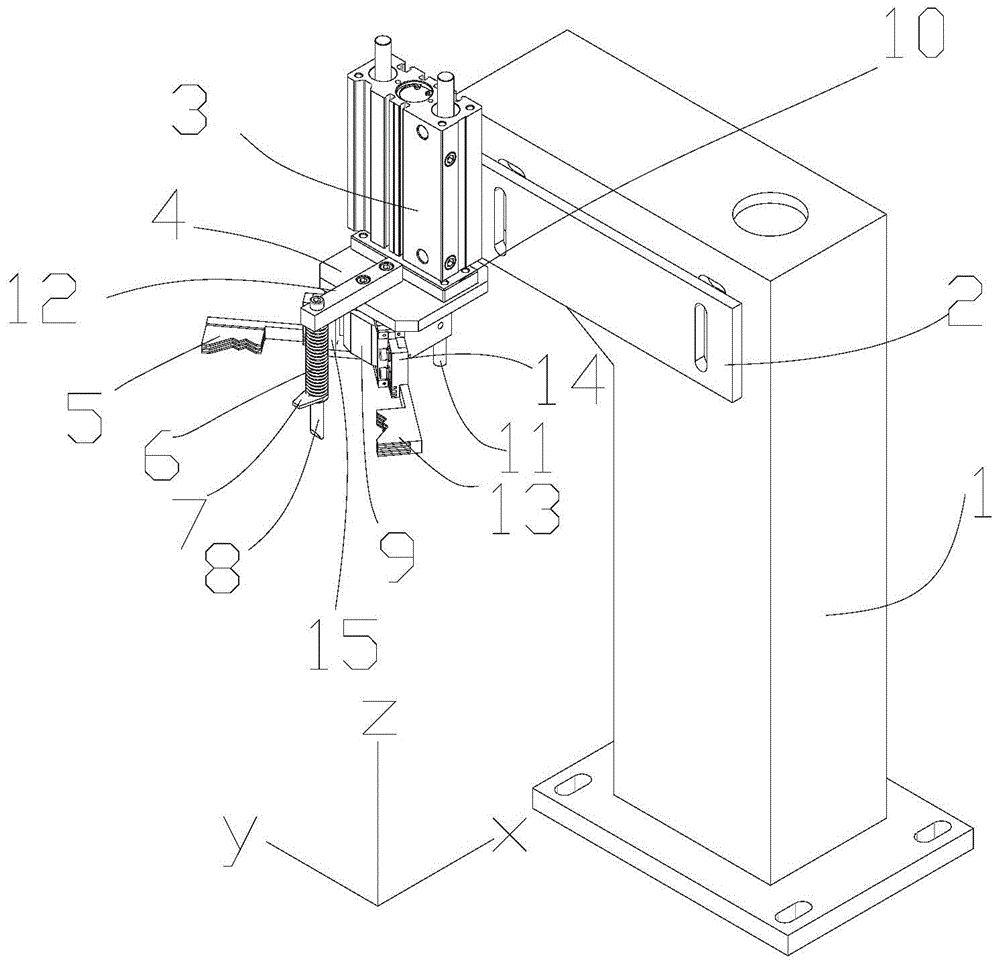

[0043] Such as figure 1 As shown, an embodiment of the cable management mechanism of the present invention includes: a support platform 1, a mounting plate 2, a cylinder 3, an adjustment device (which includes: a bearing plate 4, a pull rod 11, a cantilever 12, a guide rod 8, a spring 6, Fixing sheet 7), cable management clip (it includes: clip sheet, clip arm, clip hand cylinder 9), wherein:

[0044] The chassis of the support platform 1 is placed horizontally, and the remaining parts are above the chassis and vertically upward, and are used to fix the whole mechanism on the edge of a certain working platform or assembly line.

[0045] One side of the mounting plate 2 is fixed on the side of the support platform 1 with screws, and the other side extends out of the support platform 1 for installing the cylinder 3 and the adjustment device; generally, the length of the mounting plate 2 is selected to be longer than the side of the support platform 1 , so that the working parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com