Flat elevator accompanying cable for super high-rise super high-speed elevators

An accompanying cable and ultra-high-speed technology, applied in the direction of flat/ribbon cables, insulated cables, cables, etc., can solve the problems that coaxial cables and TPS shielded wires cannot meet the transmission of high-definition images, etc., and achieve dynamic balance and movement stability Good performance and small torsion angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

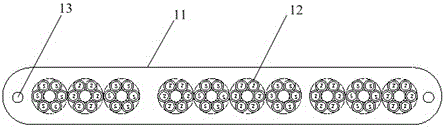

[0062] A flat type elevator accompanying cable for super high-rise ultra-high-speed elevators, such as Figure 1-3 As shown, the flat sheath 11 is included, and 10 core units 12 and load-bearing elements 13 are arranged in a straight line in the flat sheath 11 .

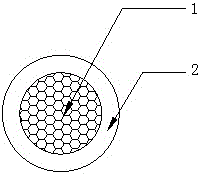

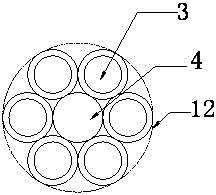

[0063] The core unit 12 has a primary cabling structure. Select a cross-sectional area of 0.5mm 2 (20 / 0.18mm) 5 kinds of soft structure bundled copper wires are used as the conductor core 1, and the PE insulating material 2 is coated outside the conductor core 1 as the insulating core 3; a PVC is surrounded by 6 insulating cores 3 The core unit 12 is formed by stranding the filler core 4 in one stranding, the twisting direction of the stranding in the stranding direction is the same as that of the insulated core conductor strands, and the cabled pitch is 10-12 times the outer diameter of the core unit, which can be used The non-back-twisting equipment forms the cable, and the core pay-off tension is properly cont...

Embodiment 2

[0067] A flat type elevator accompanying cable for super high-rise ultra-high-speed elevators, such as Figure 4-5 As shown, including the flat sheath 21, there are 6 core units 22 and load-bearing elements 23 arranged in a straight line in the flat sheath 21, and there are 4 units in the middle of the core unit 22 in the flat sheath. TPS shielded pair composite optical cable 24.

[0068] The core unit 22 has a primary cabling structure. Select the cross-sectional area as 1.0mm 2 (40 / 0.18mm) 5 kinds of soft structure bundled copper wires are used as the conductor core, and the PE insulating material is coated outside the conductor core as the insulating core; it is composed of 6 insulating cores around a PVC lining core at one time. The cable is twisted to form a core unit 22. The twisting direction of the first cable is the same as the direction of the insulated core conductor bundle, and the cable pitch is 10-12 times the outer diameter of the core unit. It can be cabled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com