Connecting device for U-shaped steel bracket

A technology of connecting device and section steel, which is used in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of damage to the support body, the collapse of the cable connection, and the easy breakage of the curved beam, so as to avoid connection failure, The effect of ensuring connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

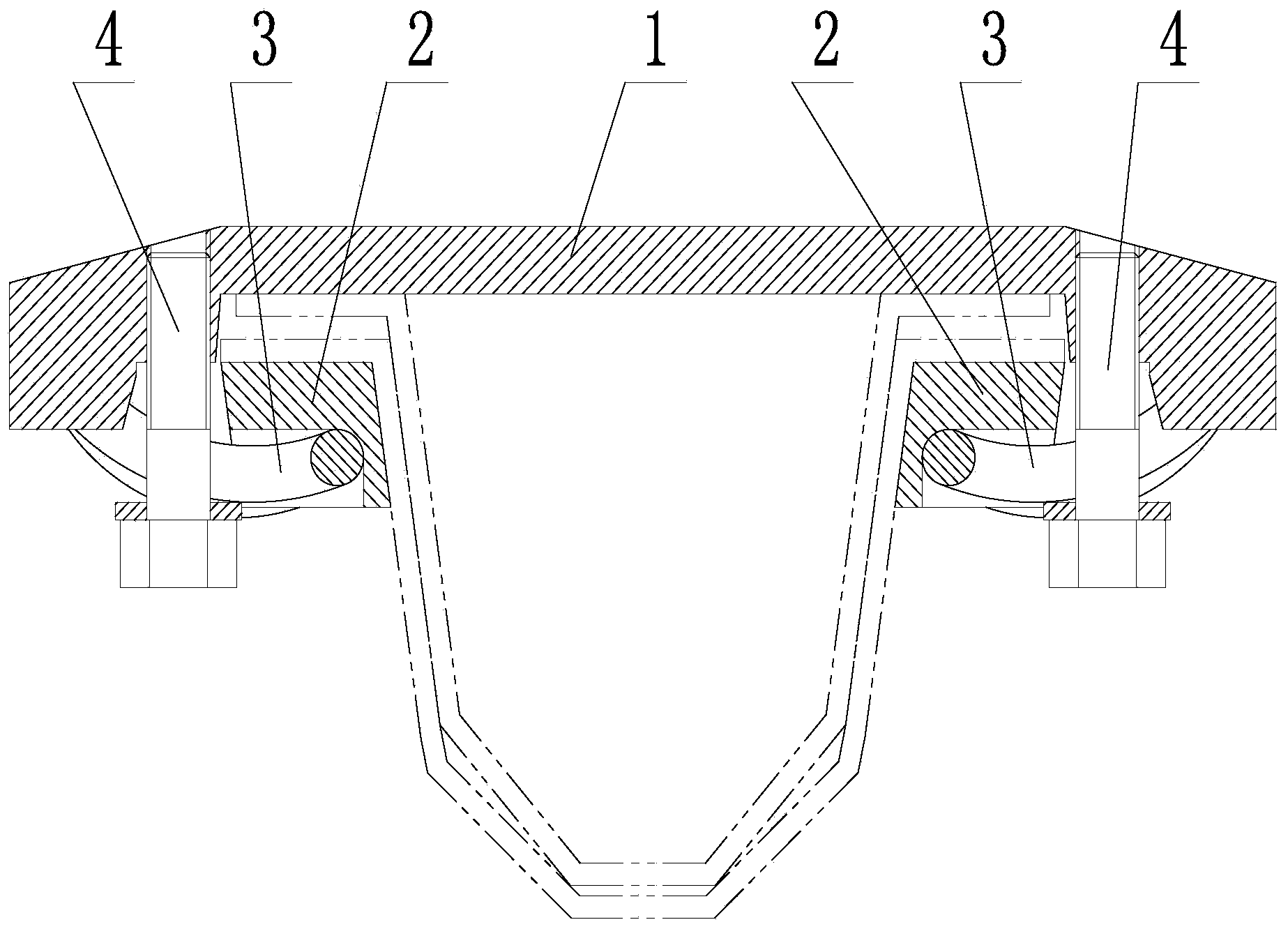

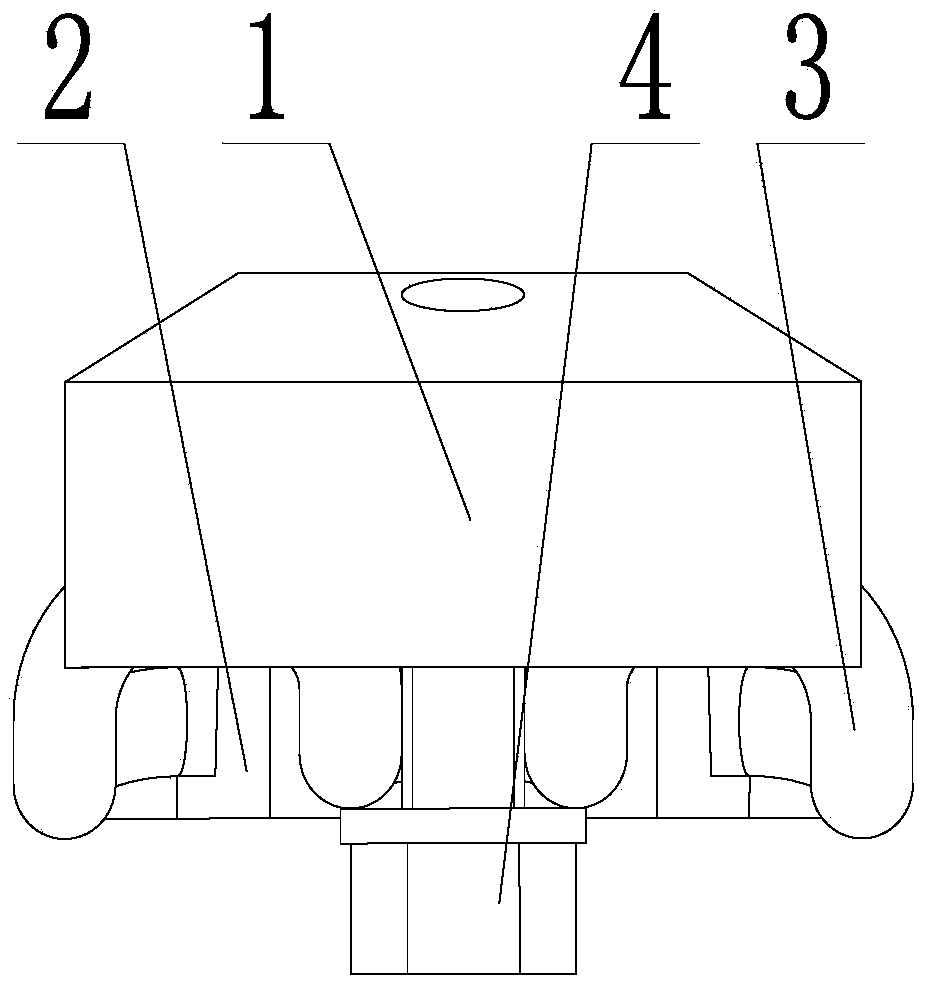

[0017] like figure 1 , 2 , 3, a connecting device for a U-shaped steel bracket, including a top cover 1, a base 2 and a W-shaped elastic fastener 3, the top cover 1 corresponds to the outer side arc beam, and the base 2 corresponds to the inner side arc beam. The side arc beam corresponds; the top of the W-shaped elastic fastener 3 corresponds to the base 2, the tail end of the W-shaped elastic fastener 3 corresponds to the top cover 1, and the W-shaped elastic fastener 3 passes through the lock. Tight bolt 4 is fixed on the top cover 1.

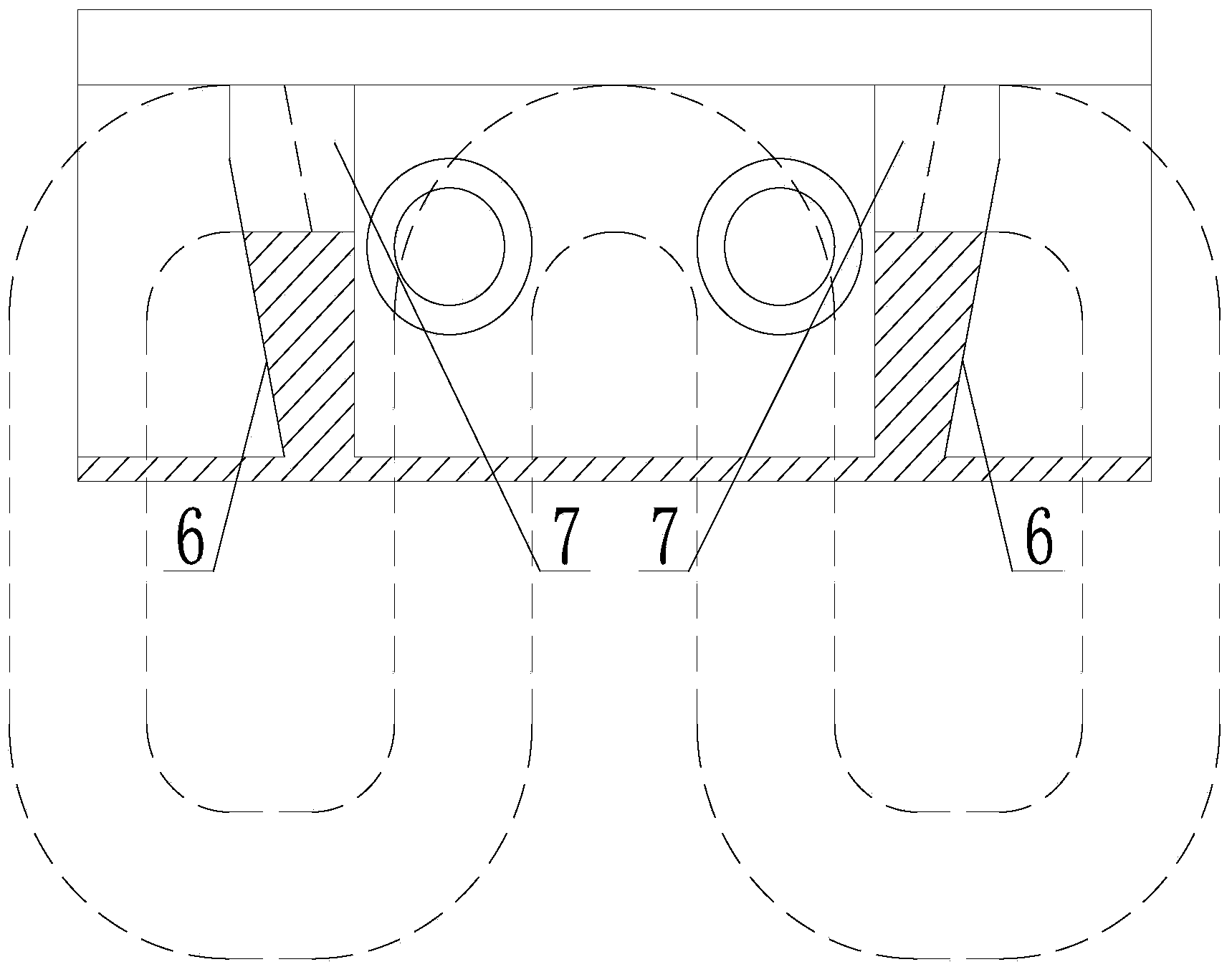

[0018] Two slopes 6 are arranged on the base 2, and the two slopes 6 are arranged symmetrically, and limit holes 7 are arranged at the ends of the two slopes 6; It is a hook structure, and the limit hole 7 corresponds to the hook structure at the end of the arm of the W-shaped elastic fastener 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com