Steel pipe discharge mechanism

A technology of unloading mechanism and steel pipe, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of heavy workload and poor safety of operators, and achieve the goal of reducing labor intensity, reducing collisions, ensuring the degree of automation and continuous production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

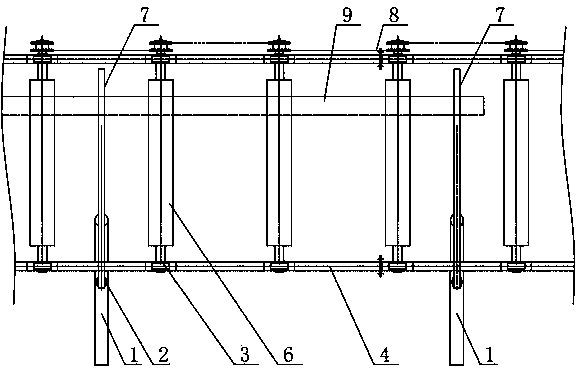

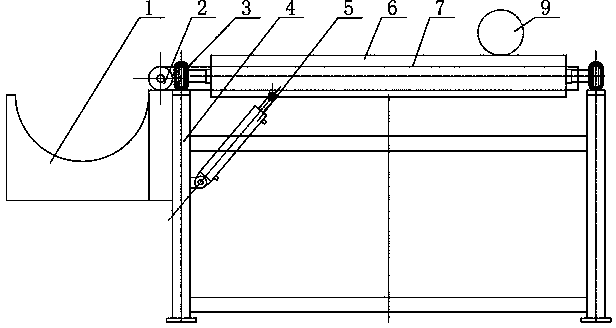

[0013] Such as figure 1 In the unloading section of the steel pipe production line shown, several rollers 6 are supported on the frame 4 of the assembly line by the rollers 3 at both ends to form the main roller table, and are driven and rotated by the traction chain 8 at one end of the rollers 6 to drive the rollers above the rollers 6. Steel pipe 9 is sent forward. Turning plate 7 of the present invention is arranged between two rollers 6, as figure 2 As shown, the flap 7 of the cantilever structure is pivotally installed on the frame 4 through the rotating shaft 2 at one end, and the collecting frame 1 is installed on the outside of the side of the rotating shaft 2 of the frame 4, and the inside is installed with Overturning cylinder 5, one end of overturning cylinder 5 is pivotally connected to frame 4, and the other end is pivotall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com