A supermarket shopping trolley with variable telescopic distance and its realization method

A technology for trolleys and supermarkets, applied to trolleys, multi-axis trolleys, motor vehicles, etc., can solve the problems of large telescopic distance, short service life, and no protective device, etc., to reduce processing difficulty, improve service life, and increase the bottom The effect of rack slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

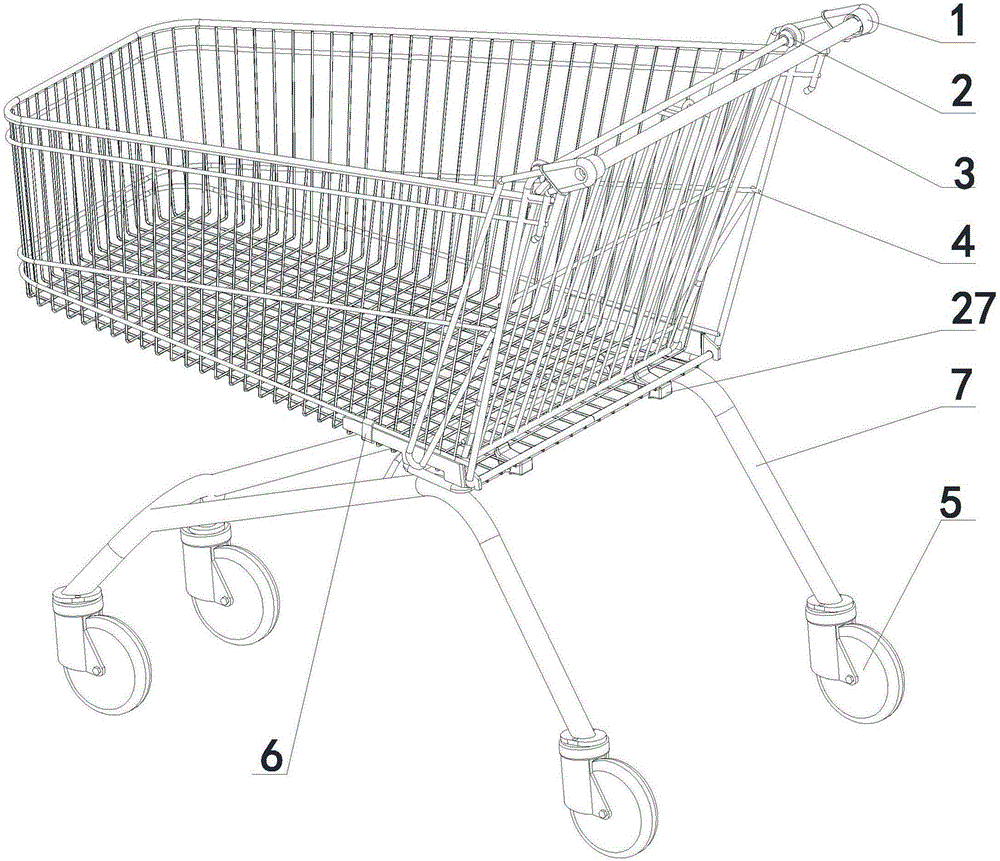

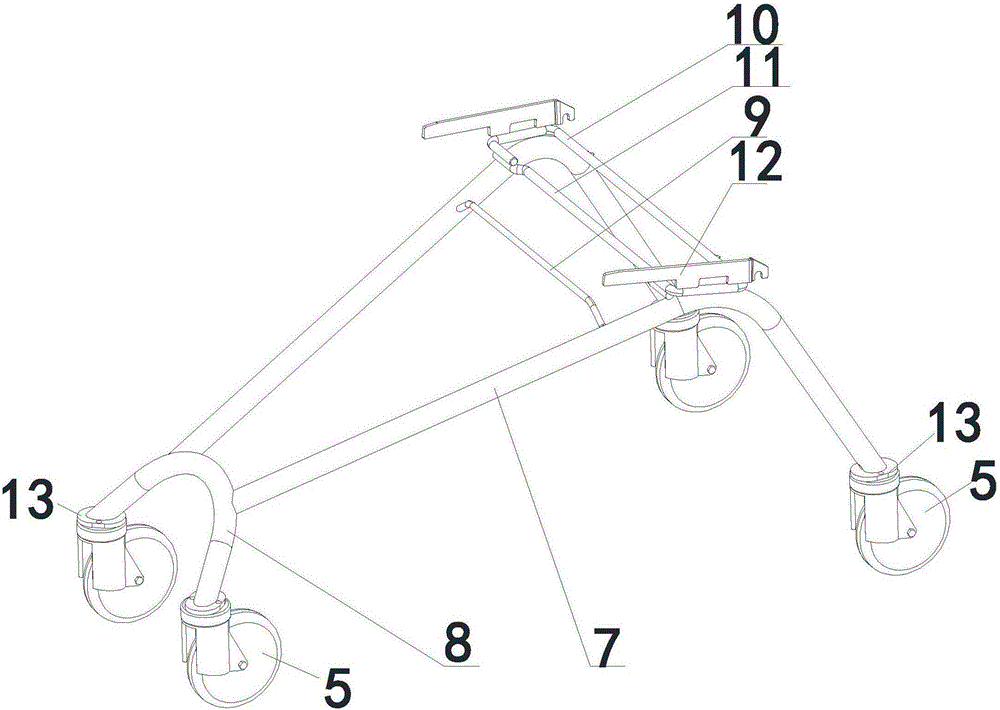

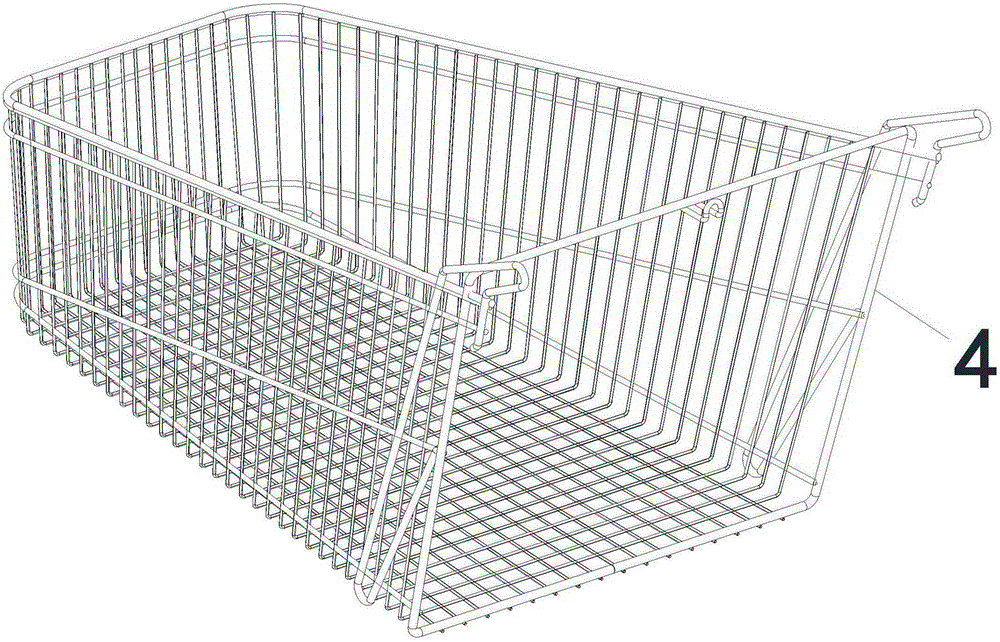

[0058] Such as Figure 1-9 As shown in and 14, a supermarket shopping trolley with variable nesting distance includes a handle 1, a handrail net installation part 2, a handrail net 3, a basket 4, an anti-collision piece 27, a chassis, casters 5 and buckles 6 Wherein, the handle 1 is fixedly connected with the upper end of the basket 4, the upper end of the basket 4 is provided with a crossbeam, and the two ends of the crossbeam are respectively provided with handrail net installation parts 2, the handrail net 3 is connected with the handrail net installation part 2, and the bottom frame passes through The buckle 6 is connected with the basket 4, the anti-collision member 27 is located at the bottom of the basket 4, and the bottom frame includes the bottom frame pipe 7, the front connecting pipe 8, the front positioning rod 9, the rear positioning rod 10, the lower connecting rod 11, the connection Plate 12 and caster mounting plate 13; the front connecting pipe 8 is in the sha...

Embodiment 2

[0075] Such as Figure 10-13 As shown, the difference between this embodiment and Embodiment 1 is that the anti-collision member 27 in this embodiment is a second anti-collision member, and there are several second anti-collision members. The second anti-collision member includes a body 14, The rear end of the main body 14 is bent backward, and a rotating part 15 is provided on the main body 14. The rotating part 15 is in interference fit with the rear end of the rear positioning rod 10. The upper and lower ends of the main body 14 are respectively a first arc end 16 and a second arc end 17 , the first arc end 16 rotates in the grid of the basket 4, the bottom of the main body 14 when it is horizontal is higher than the front positioning rod 9 of the next supermarket shopping trolley when it is nested, and the second arc end when the body is vertical 17 buckle the door frame bottom beam 28 of the basket. In this embodiment, the angle between the front end of the chassis pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com